Optional Configurations

Optional Hose Position

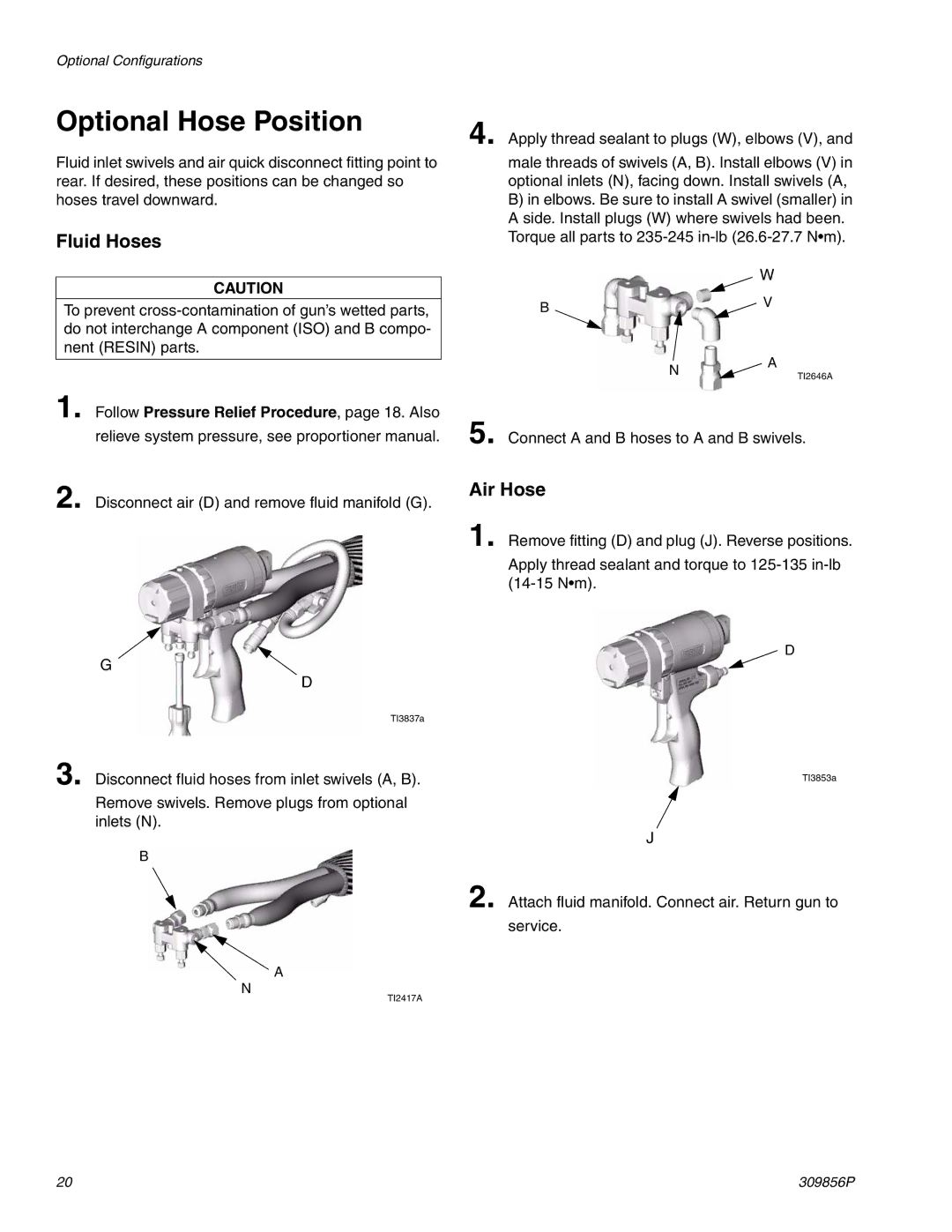

Fluid inlet swivels and air quick disconnect fitting point to rear. If desired, these positions can be changed so hoses travel downward.

Fluid Hoses

CAUTION

To prevent

1. Follow Pressure Relief Procedure, page 18. Also

relieve system pressure, see proportioner manual.

2. Disconnect air (D) and remove fluid manifold (G).

G

D

TI3837a

3. Disconnect fluid hoses from inlet swivels (A, B).

Remove swivels. Remove plugs from optional inlets (N).

B

A

N

TI2417A

4. Apply thread sealant to plugs (W), elbows (V), and

male threads of swivels (A, B). Install elbows (V) in optional inlets (N), facing down. Install swivels (A,

B)in elbows. Be sure to install A swivel (smaller) in A side. Install plugs (W) where swivels had been. Torque all parts to

|

| W |

B |

| V |

|

| |

| N | A |

| TI2646A | |

|

|

5. Connect A and B hoses to A and B swivels.

Air Hose

1. Remove fitting (D) and plug (J). Reverse positions.

Apply thread sealant and torque to

D

TI3853a

J

2. Attach fluid manifold. Connect air. Return gun to

service.

20 | 309856P |