Installation

Connect Fluid Line

Before connecting the fluid line, blow it out with air and flush it with solvent. Use solvent that is compat- ible with the fluid to be sprayed.

A fluid drain valve(s) is required in your system to assist in relieving fluid pressure in the displacement pump, hose and gun; triggering the gun to relieve pressure may not be sufficient.

A fluid pressure regulator must be installed in the system if the pump's maximum working pressure exceeds the gun's maximum fluid working pressure (see the front cover).

1.Install a fluid filter and drain valve(s) close to the pump's fluid outlet.

2.Install a fluid pressure regulator to control fluid pres- sure to the gun.

Some applications require

3.Install a fluid shutoff valve to shut off the fluid supply to the gun.

4.Install an

5.In a circulating system, connect a grounded fluid supply hose to the gun fluid fitting. Connect a grounded return hose to the other port.

In a

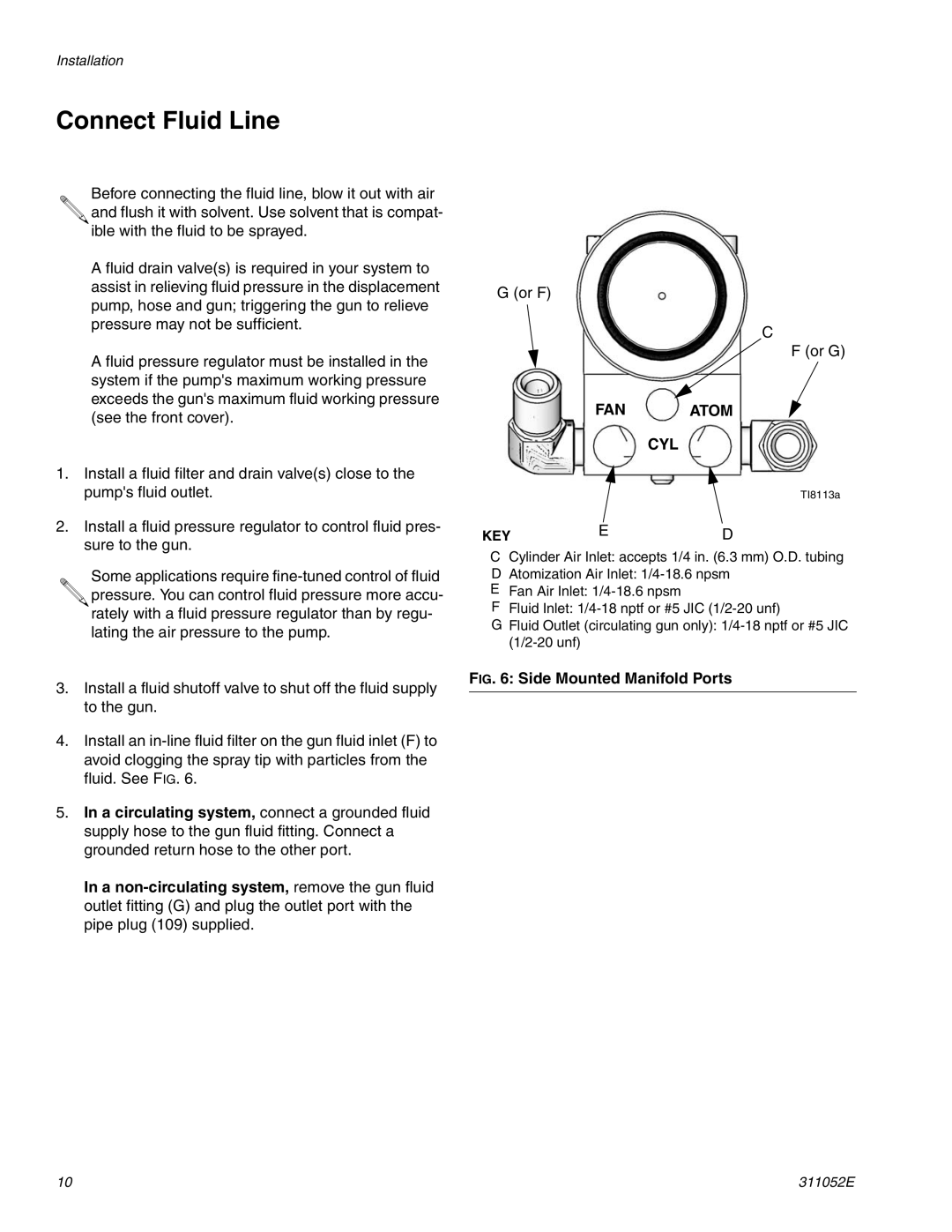

G (or F)

C

F (or G)

FAN ATOM

CYL

TI8113a

KEY | E | D |

CCylinder Air Inlet: accepts 1/4 in. (6.3 mm) O.D. tubing D Atomization Air Inlet:

E Fan Air Inlet:

F Fluid Inlet:

G Fluid Outlet (circulating gun only):

FIG. 6: Side Mounted Manifold Ports

10 | 311052E |