Maintenance

Maintenance

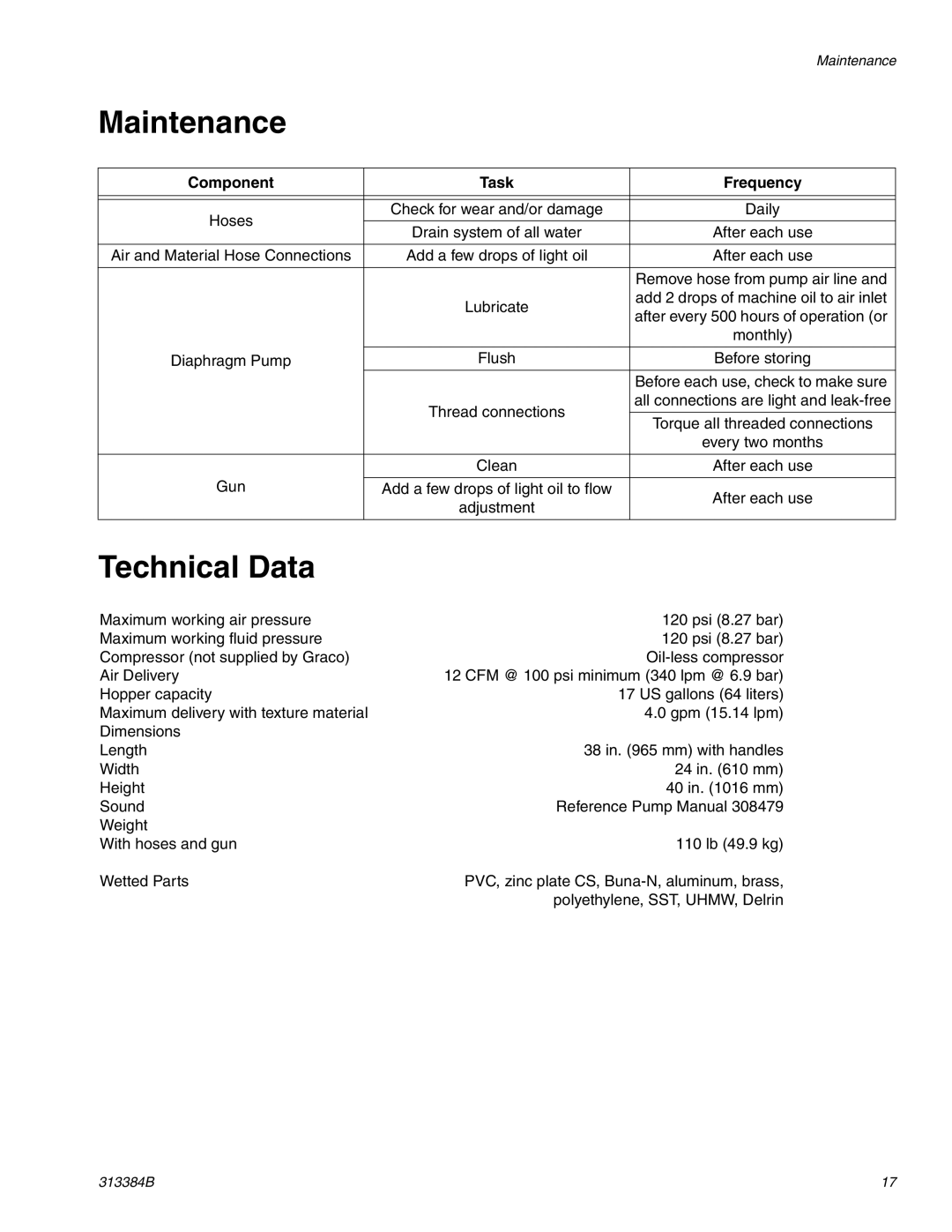

Component | Task | Frequency | |

|

|

| |

|

|

| |

Hoses | Check for wear and/or damage | Daily | |

|

| ||

Drain system of all water | After each use | ||

| |||

|

|

| |

Air and Material Hose Connections | Add a few drops of light oil | After each use | |

|

|

| |

|

| Remove hose from pump air line and | |

| Lubricate | add 2 drops of machine oil to air inlet | |

| after every 500 hours of operation (or | ||

|

| ||

|

| monthly) | |

|

|

| |

Diaphragm Pump | Flush | Before storing | |

|

| Before each use, check to make sure | |

| Thread connections | all connections are light and | |

|

| ||

| Torque all threaded connections | ||

|

| ||

|

| every two months | |

|

|

| |

| Clean | After each use | |

Gun |

|

| |

Add a few drops of light oil to flow | After each use | ||

| adjustment | ||

|

| ||

|

|

|

Technical Data

Maximum working air pressure Maximum working fluid pressure Compressor (not supplied by Graco) Air Delivery

Hopper capacity

Maximum delivery with texture material Dimensions

Length

Width

Height

Sound

Weight

With hoses and gun

Wetted Parts

120 psi (8.27 bar)

120 psi (8.27 bar)

17 US gallons (64 liters)

4.0 gpm (15.14 lpm)

38 in. (965 mm) with handles

24 in. (610 mm)

40 in. (1016 mm) Reference Pump Manual 308479

110 lb (49.9 kg)

PVC, zinc plate CS,

313384B | 17 |