Maintenance

Capture Tank

The interior surfaces of the hood capture tank should be wiped down weekly.

Filters

The Grease Grabber filters (bead filters) require visually inspection (not removed from hood) two weeks after

To inspect the bead filters, remove the fasteners holding the access doors; each door has five (5) fasteners. Remove every other door to inspect the filters.

After inspecting the filters, put the access doors back on and put the fasteners back in. Be careful not to

Floats

The floats need to be inspected two weeks after

The float can be inspected by first turning the disconnect switch on the control cabinet to the ‘OFF’ position. Then remove the large access panel door. Once the access panel

is removed, you will have access to the floats.

Access Panel Door

Float Installed

The Grease Grabber filters (bead filters) need to be removed from the hood once every three months to visually inspect and ensure the filters are structurally sound.

Remove all the doors and remove the filters for inspection. Depending on the equipment under the hood, it will probably be easier to remove the filters from the right side of each hood. Slide the other filters down to the end access door for removal.

After inspecting the filters, place them back in the hood. Be careful to install the filters with the handles up and make sure not to hit the fire detection line when removing or installing the filters. Ensure no gaps are between filters after installation.

If any filter appears damaged, consult factory for replacement.

Slide each float (Low Float, |

|

|

|

| |

High Float and Safety Float) |

|

|

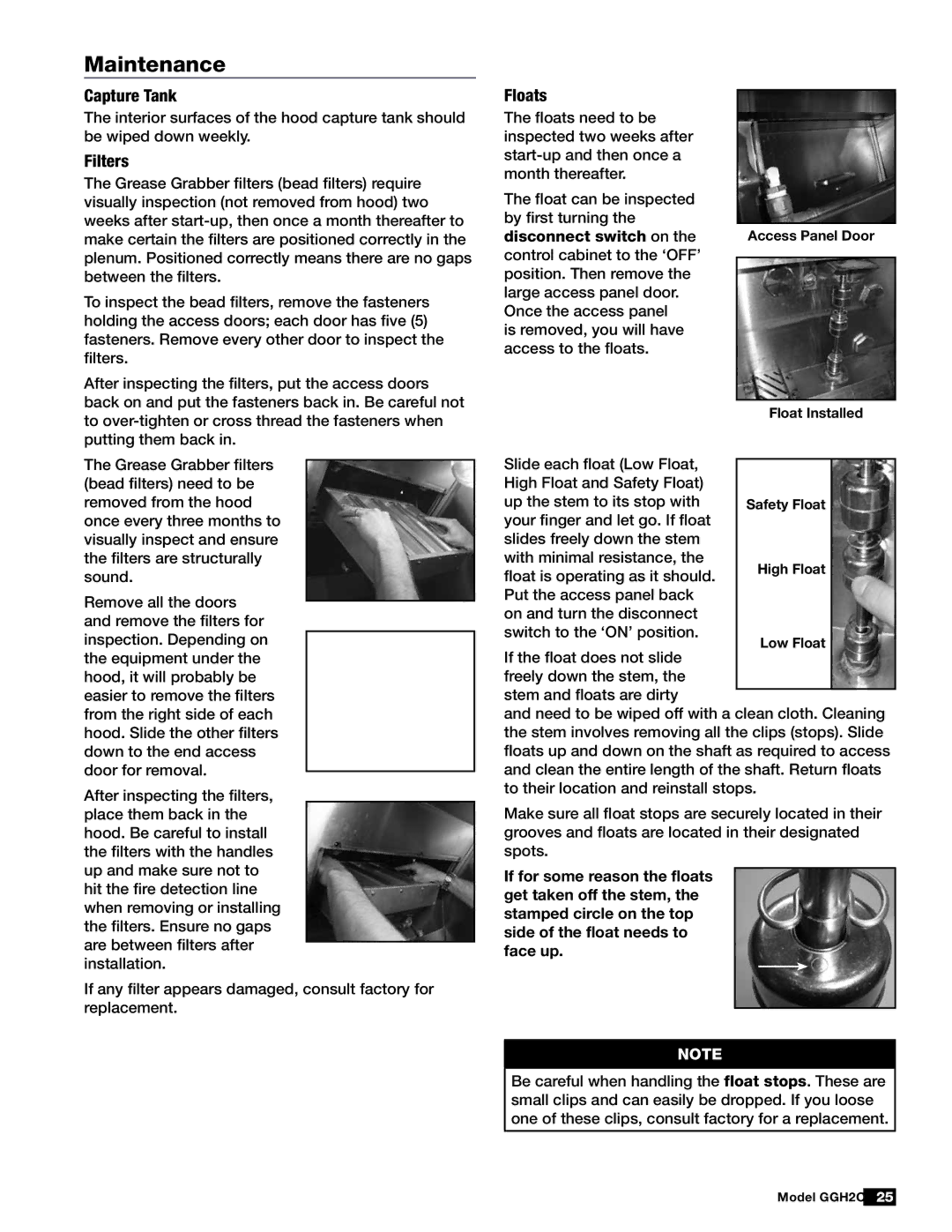

up the stem to its stop with | Safety Float |

|

your finger and let go. If float |

|

|

slides freely down the stem |

|

|

with minimal resistance, the | High Float |

|

float is operating as it should. |

| |

|

| |

Put the access panel back |

|

|

on and turn the disconnect |

|

|

switch to the ‘ON’ position. | Low Float |

|

If the float does not slide |

| |

|

| |

freely down the stem, the |

|

|

stem and floats are dirty |

|

|

|

|

and need to be wiped off with a clean cloth. Cleaning the stem involves removing all the clips (stops). Slide floats up and down on the shaft as required to access and clean the entire length of the shaft. Return floats to their location and reinstall stops.

Make sure all float stops are securely located in their grooves and floats are located in their designated spots.

If for some reason the floats get taken off the stem, the stamped circle on the top side of the float needs to face up.

NOTE

Be careful when handling the float stops. These are small clips and can easily be dropped. If you loose one of these clips, consult factory for a replacement.

®

Model GGH2O 25