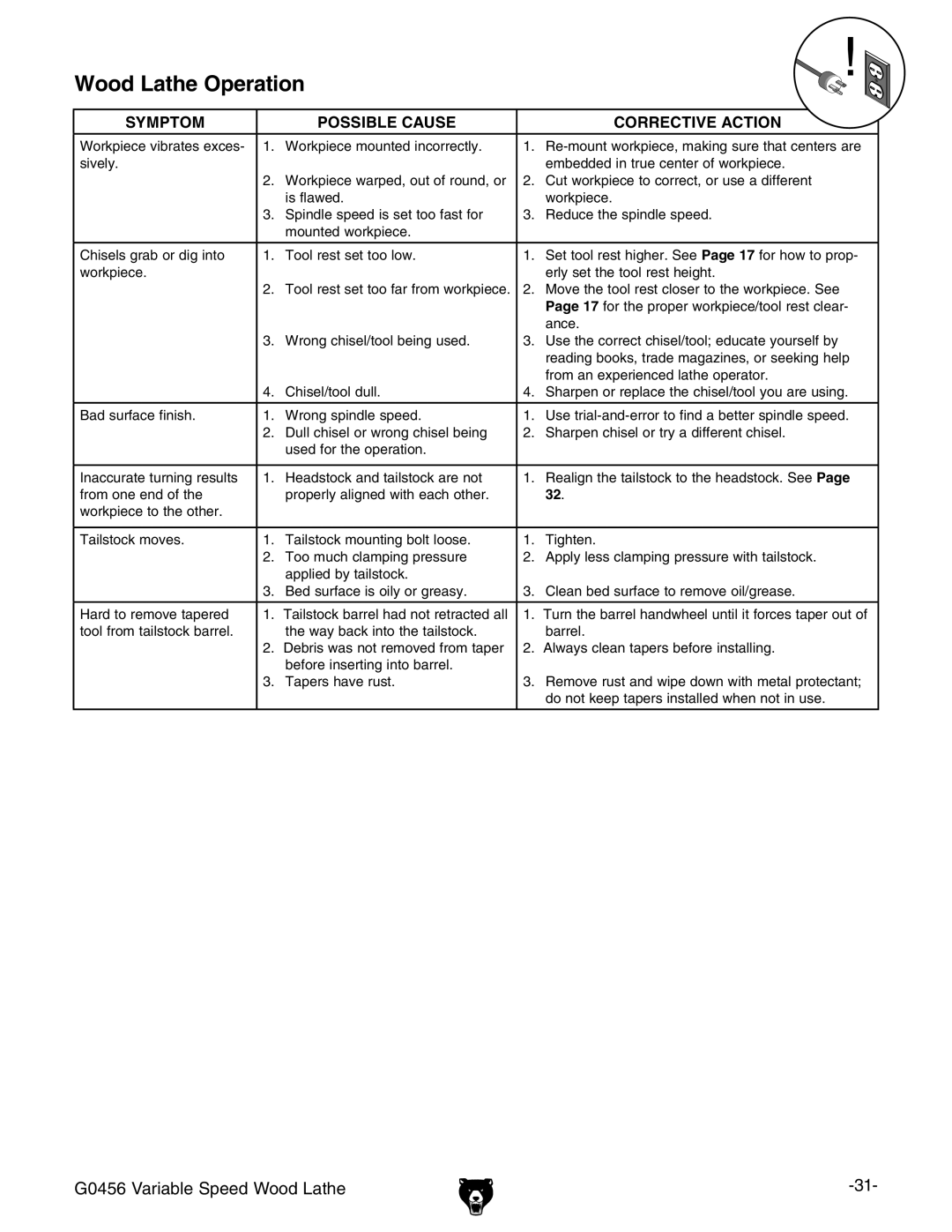

Wood Lathe Operation

SYMPTOM |

| POSSIBLE CAUSE |

| CORRECTIVE ACTION |

|

|

|

|

|

Workpiece vibrates exces- | 1. | Workpiece mounted incorrectly. | 1. | |

sively. |

|

|

| embedded in true center of workpiece. |

| 2. | Workpiece warped, out of round, or | 2. | Cut workpiece to correct, or use a different |

|

| is flawed. |

| workpiece. |

| 3. | Spindle speed is set too fast for | 3. | Reduce the spindle speed. |

|

| mounted workpiece. |

|

|

|

|

|

|

|

Chisels grab or dig into | 1. | Tool rest set too low. | 1. | Set tool rest higher. See Page 17 for how to prop- |

workpiece. |

|

|

| erly set the tool rest height. |

| 2. | Tool rest set too far from workpiece. | 2. | Move the tool rest closer to the workpiece. See |

|

|

|

| Page 17 for the proper workpiece/tool rest clear- |

|

|

|

| ance. |

| 3. | Wrong chisel/tool being used. | 3. | Use the correct chisel/tool; educate yourself by |

|

|

|

| reading books, trade magazines, or seeking help |

|

|

|

| from an experienced lathe operator. |

| 4. | Chisel/tool dull. | 4. | Sharpen or replace the chisel/tool you are using. |

|

|

|

|

|

Bad surface finish. | 1. | Wrong spindle speed. | 1. | Use |

| 2. | Dull chisel or wrong chisel being | 2. | Sharpen chisel or try a different chisel. |

|

| used for the operation. |

|

|

|

|

|

|

|

Inaccurate turning results | 1. | Headstock and tailstock are not | 1. | Realign the tailstock to the headstock. See Page |

from one end of the |

| properly aligned with each other. |

| 32. |

workpiece to the other. |

|

|

|

|

|

|

|

|

|

Tailstock moves. | 1. | Tailstock mounting bolt loose. | 1. | Tighten. |

| 2. | Too much clamping pressure | 2. | Apply less clamping pressure with tailstock. |

|

| applied by tailstock. |

|

|

| 3. | Bed surface is oily or greasy. | 3. | Clean bed surface to remove oil/grease. |

|

|

|

|

|

Hard to remove tapered | 1. | Tailstock barrel had not retracted all | 1. | Turn the barrel handwheel until it forces taper out of |

tool from tailstock barrel. |

| the way back into the tailstock. |

| barrel. |

| 2. | Debris was not removed from taper | 2. | Always clean tapers before installing. |

|

| before inserting into barrel. |

|

|

| 3. | Tapers have rust. | 3. | Remove rust and wipe down with metal protectant; |

|

|

|

| do not keep tapers installed when not in use. |

|

|

|

|

|

G0456 Variable Speed Wood Lathe |