4.Thread the faceplate onto the headstock spindle and tighten securely.

Note: If screws cannot be placed in the workpiece, then a backing block can be glued to the workpiece and attached to the faceplate with screws.

To mount your workpiece to a backing block:

1.Make the backing block from a piece of scrap wood that is flat on both sides.

2.Locate and mark the center of both the workpiece and the backing block.

3.Drill a 1⁄4" hole in the center of the backing block.

4.Glue the center of the backing block to the center of the workpiece (look through the drilled hole to line up centers), clamp the backing block to the workpiece, and wait for the glue to cure according to the manufactur- er’s recommendation.

Changing Speeds

To change between High and Low speeds:

1.DISCONNECT LATHE POWER SOURCE!

2.Remove the front and rear headstock covers (located just behind the sanding disc).

3.Loosen the adjustment bolt (Figure 28).

4.Use the handle to loosen the belt.

5.Place the belt on the next pulley step to select the other speed range.

6.Use the handle to tension the belt, then tighten adjustment bolt to keep the belt tight.

7.Replace the front and rear covers.

Sanding/Finishing

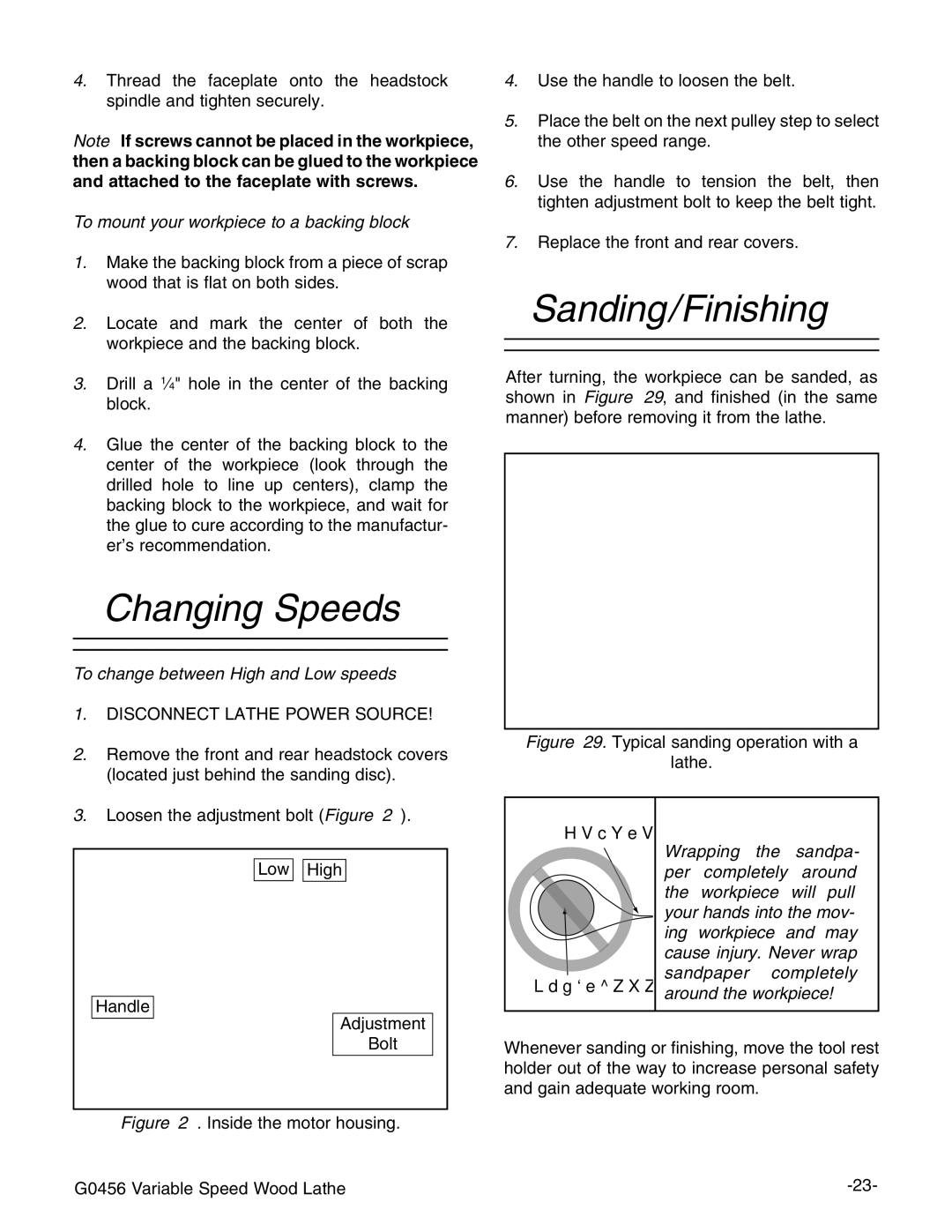

After turning, the workpiece can be sanded, as shown in Figure 29, and finished (in the same manner) before removing it from the lathe.

Figure 29. Typical sanding operation with a

lathe.

Low High

Handle

Adjustment

���������

���������

Wrapping the sandpa- per completely around the workpiece will pull your hands into the mov- ing workpiece and may cause injury. Never wrap sandpaper completely around the workpiece!

Bolt