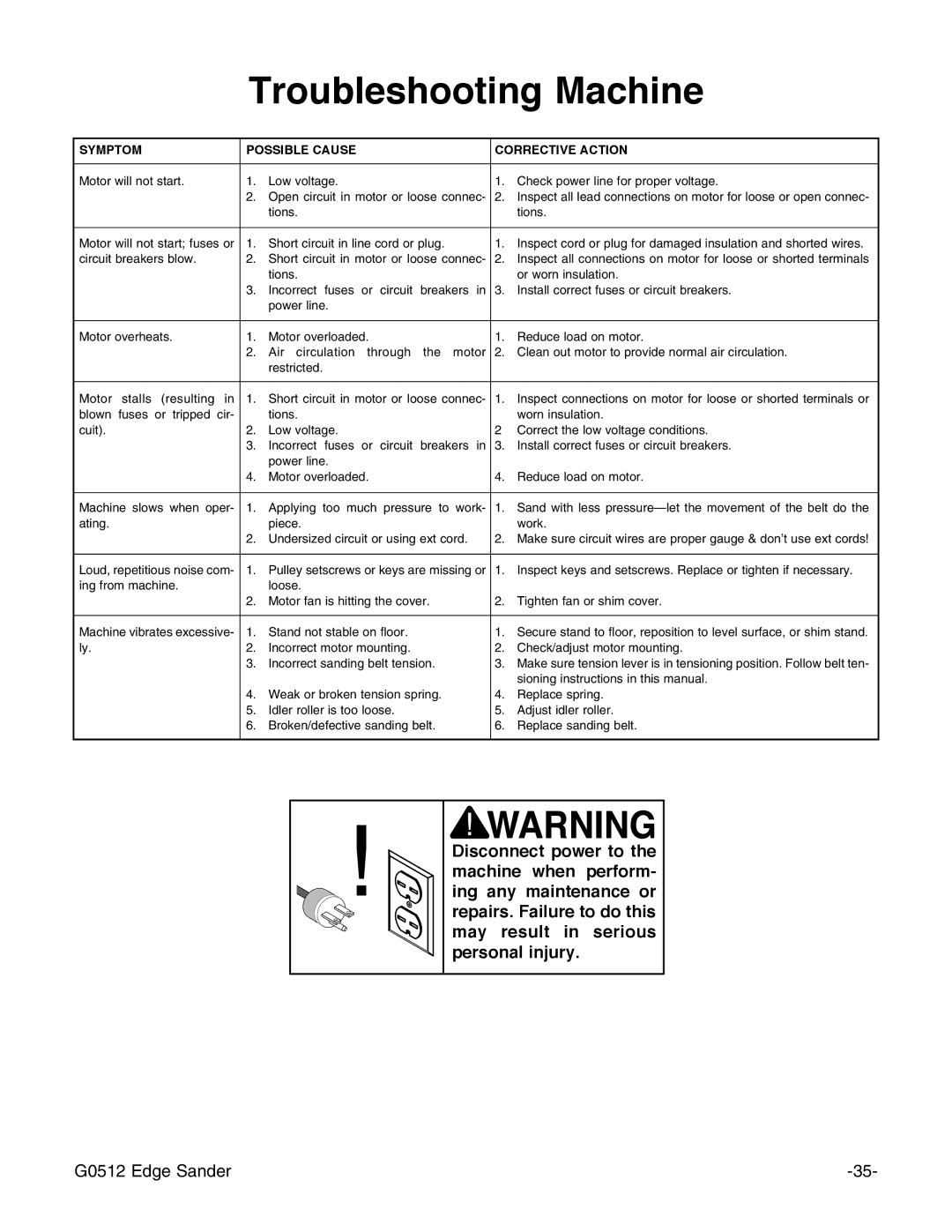

Troubleshooting Machine

SYMPTOM | POSSIBLE CAUSE | CORRECTIVE ACTION | ||

|

|

|

|

|

Motor will not start. | 1. | Low voltage. | 1. | Check power line for proper voltage. |

| 2. | Open circuit in motor or loose connec- | 2. | Inspect all lead connections on motor for loose or open connec- |

|

| tions. |

| tions. |

|

|

|

|

|

Motor will not start; fuses or | 1. | Short circuit in line cord or plug. | 1. | Inspect cord or plug for damaged insulation and shorted wires. |

circuit breakers blow. | 2. | Short circuit in motor or loose connec- | 2. | Inspect all connections on motor for loose or shorted terminals |

|

| tions. |

| or worn insulation. |

| 3. | Incorrect fuses or circuit breakers in | 3. | Install correct fuses or circuit breakers. |

|

| power line. |

|

|

|

|

|

|

|

Motor overheats. | 1. | Motor overloaded. | 1. | Reduce load on motor. |

| 2. | Air circulation through the motor | 2. | Clean out motor to provide normal air circulation. |

|

| restricted. |

|

|

|

|

|

|

|

Motor stalls (resulting in | 1. | Short circuit in motor or loose connec- | 1. | Inspect connections on motor for loose or shorted terminals or |

blown fuses or tripped cir- |

| tions. |

| worn insulation. |

cuit). | 2. | Low voltage. | 2 | Correct the low voltage conditions. |

| 3. | Incorrect fuses or circuit breakers in | 3. | Install correct fuses or circuit breakers. |

|

| power line. |

|

|

| 4. | Motor overloaded. | 4. | Reduce load on motor. |

|

|

|

|

|

Machine slows when oper- | 1. | Applying too much pressure to work- | 1. | Sand with less |

ating. |

| piece. |

| work. |

| 2. | Undersized circuit or using ext cord. | 2. | Make sure circuit wires are proper gauge & don’t use ext cords! |

|

|

|

|

|

Loud, repetitious noise com- | 1. | Pulley setscrews or keys are missing or | 1. | Inspect keys and setscrews. Replace or tighten if necessary. |

ing from machine. |

| loose. |

|

|

| 2. | Motor fan is hitting the cover. | 2. | Tighten fan or shim cover. |

|

|

|

|

|

Machine vibrates excessive- | 1. | Stand not stable on floor. | 1. | Secure stand to floor, reposition to level surface, or shim stand. |

ly. | 2. | Incorrect motor mounting. | 2. | Check/adjust motor mounting. |

| 3. | Incorrect sanding belt tension. | 3. | Make sure tension lever is in tensioning position. Follow belt ten- |

|

|

|

| sioning instructions in this manual. |

| 4. | Weak or broken tension spring. | 4. | Replace spring. |

| 5. | Idler roller is too loose. | 5. | Adjust idler roller. |

| 6. | Broken/defective sanding belt. | 6. | Replace sanding belt. |

|

|

|

|

|

Disconnect power to the machine when perform- ing any maintenance or repairs. Failure to do this may result in serious personal injury.

G0512 Edge Sander |