Lubrication

The bearings are sealed and

Lubricate the areas indicated below every

1.Blade angling pivots. These should be lubricated with 6 or 7 drops of light machine oil (see Figure 77).

Blade Angling

Trunnion

Figure 77. Blade angling trunnions.

2.Sliding table ways. Spray or wipe on a light machine oil or lubricant such as Boeshield T9® the entire length of the steel rods (see Figure 78).

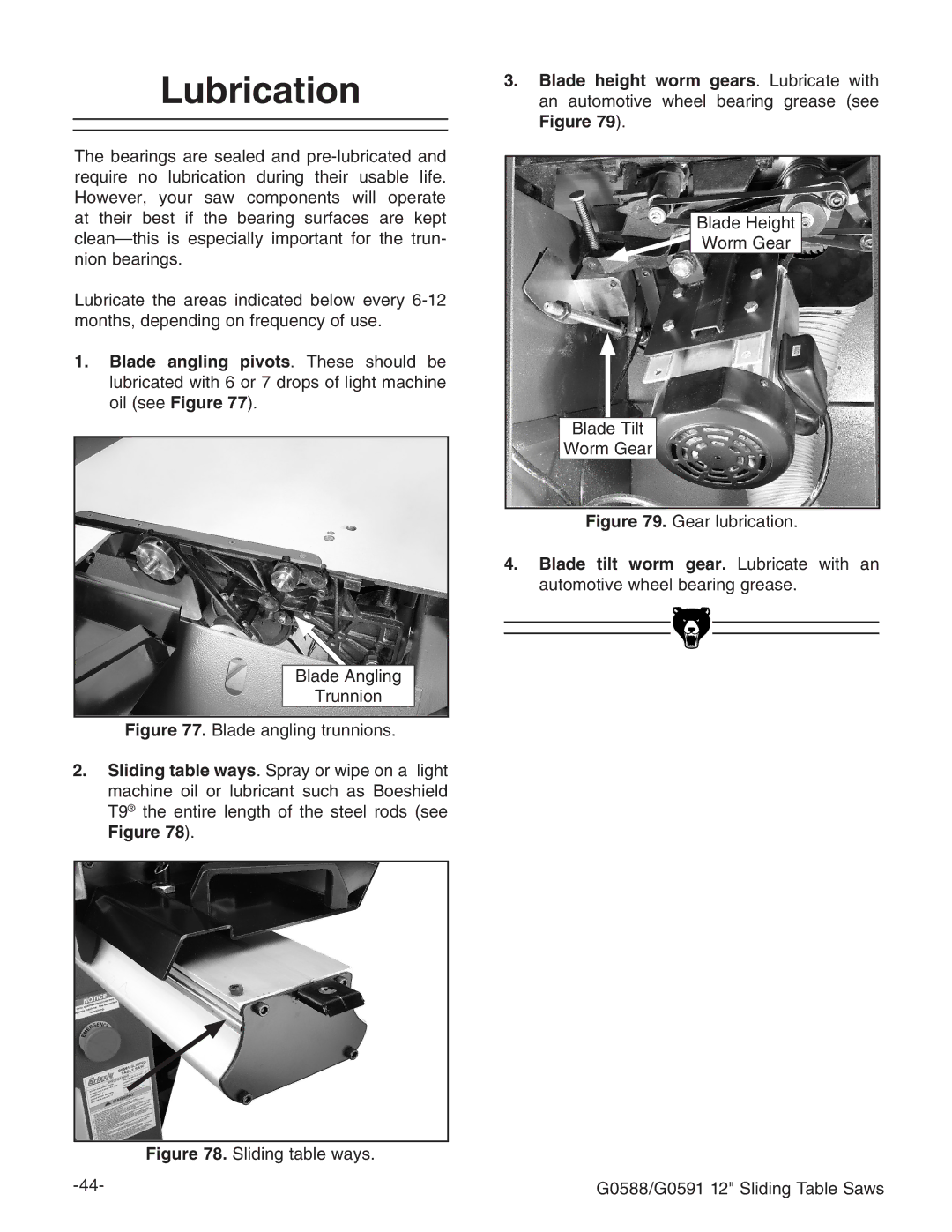

3.Blade height worm gears. Lubricate with an automotive wheel bearing grease (see Figure 79).

Blade Height

Worm Gear

Worm Gear

Blade Tilt

Worm Gear

Figure 79. Gear lubrication.

4.Blade tilt worm gear. Lubricate with an automotive wheel bearing grease.

|

|

|

| Figure 78. Sliding table ways. | |

| G0588/G0591 12" Sliding Table Saws | |