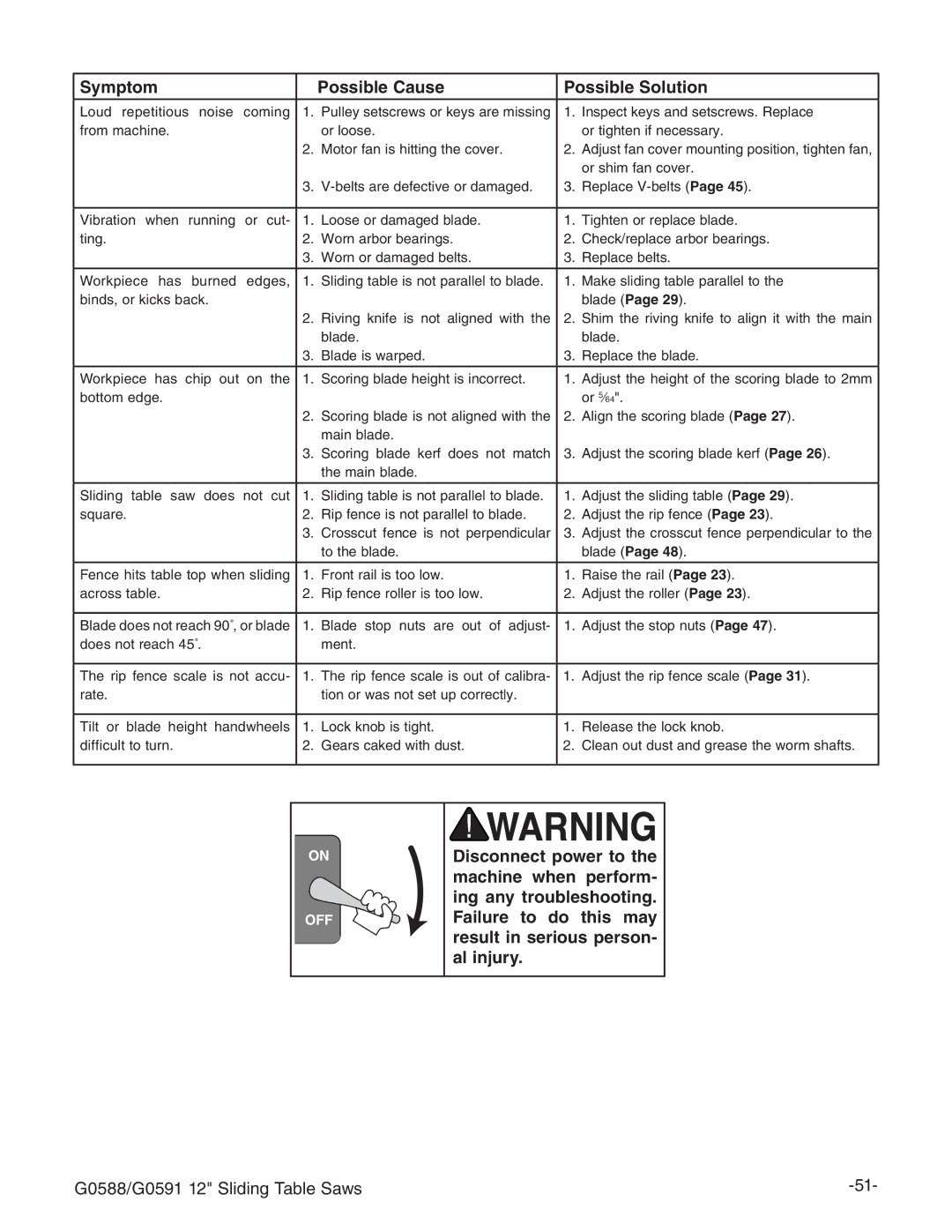

Symptom |

| Possible Cause | Possible Solution | |

Loud repetitious noise coming | 1. | Pulley setscrews or keys are missing | 1. | Inspect keys and setscrews. Replace |

from machine. |

| or loose. |

| or tighten if necessary. |

| 2. | Motor fan is hitting the cover. | 2. | Adjust fan cover mounting position, tighten fan, |

|

|

|

| or shim fan cover. |

| 3. | 3. | Replace | |

|

|

|

|

|

Vibration when running or cut- | 1. | Loose or damaged blade. | 1. | Tighten or replace blade. |

ting. | 2. | Worn arbor bearings. | 2. | Check/replace arbor bearings. |

| 3. | Worn or damaged belts. | 3. | Replace belts. |

|

|

|

|

|

Workpiece has burned edges, | 1. | Sliding table is not parallel to blade. | 1. | Make sliding table parallel to the |

binds, or kicks back. |

|

|

| blade (Page 29). |

| 2. | Riving knife is not aligned with the | 2. | Shim the riving knife to align it with the main |

|

| blade. |

| blade. |

| 3. | Blade is warped. | 3. | Replace the blade. |

|

|

|

|

|

Workpiece has chip out on the | 1. | Scoring blade height is incorrect. | 1. | Adjust the height of the scoring blade to 2mm |

bottom edge. |

|

|

| or 5⁄64". |

| 2. | Scoring blade is not aligned with the | 2. | Align the scoring blade (Page 27). |

|

| main blade. |

|

|

| 3. | Scoring blade kerf does not match | 3. | Adjust the scoring blade kerf (Page 26). |

|

| the main blade. |

|

|

|

|

|

|

|

Sliding table saw does not cut | 1. | Sliding table is not parallel to blade. | 1. | Adjust the sliding table (Page 29). |

square. | 2. | Rip fence is not parallel to blade. | 2. | Adjust the rip fence (Page 23). |

| 3. | Crosscut fence is not perpendicular | 3. | Adjust the crosscut fence perpendicular to the |

|

| to the blade. |

| blade (Page 48). |

|

|

|

|

|

Fence hits table top when sliding | 1. | Front rail is too low. | 1. | Raise the rail (Page 23). |

across table. | 2. | Rip fence roller is too low. | 2. | Adjust the roller (Page 23). |

|

|

|

|

|

Blade does not reach 90˚, or blade | 1. | Blade stop nuts are out of adjust- | 1. | Adjust the stop nuts (Page 47). |

does not reach 45˚. |

| ment. |

|

|

|

|

|

|

|

The rip fence scale is not accu- | 1. | The rip fence scale is out of calibra- | 1. | Adjust the rip fence scale (Page 31). |

rate. |

| tion or was not set up correctly. |

|

|

|

|

|

| |

Tilt or blade height handwheels | 1. | Lock knob is tight. | 1. Release the lock knob. | |

difficult to turn. | 2. | Gears caked with dust. | 2. Clean out dust and grease the worm shafts. | |

|

|

|

|

|

Disconnect power to the machine when perform- ing any troubleshooting. Failure to do this may result in serious person- al injury.

G0588/G0591 12" Sliding Table Saws |