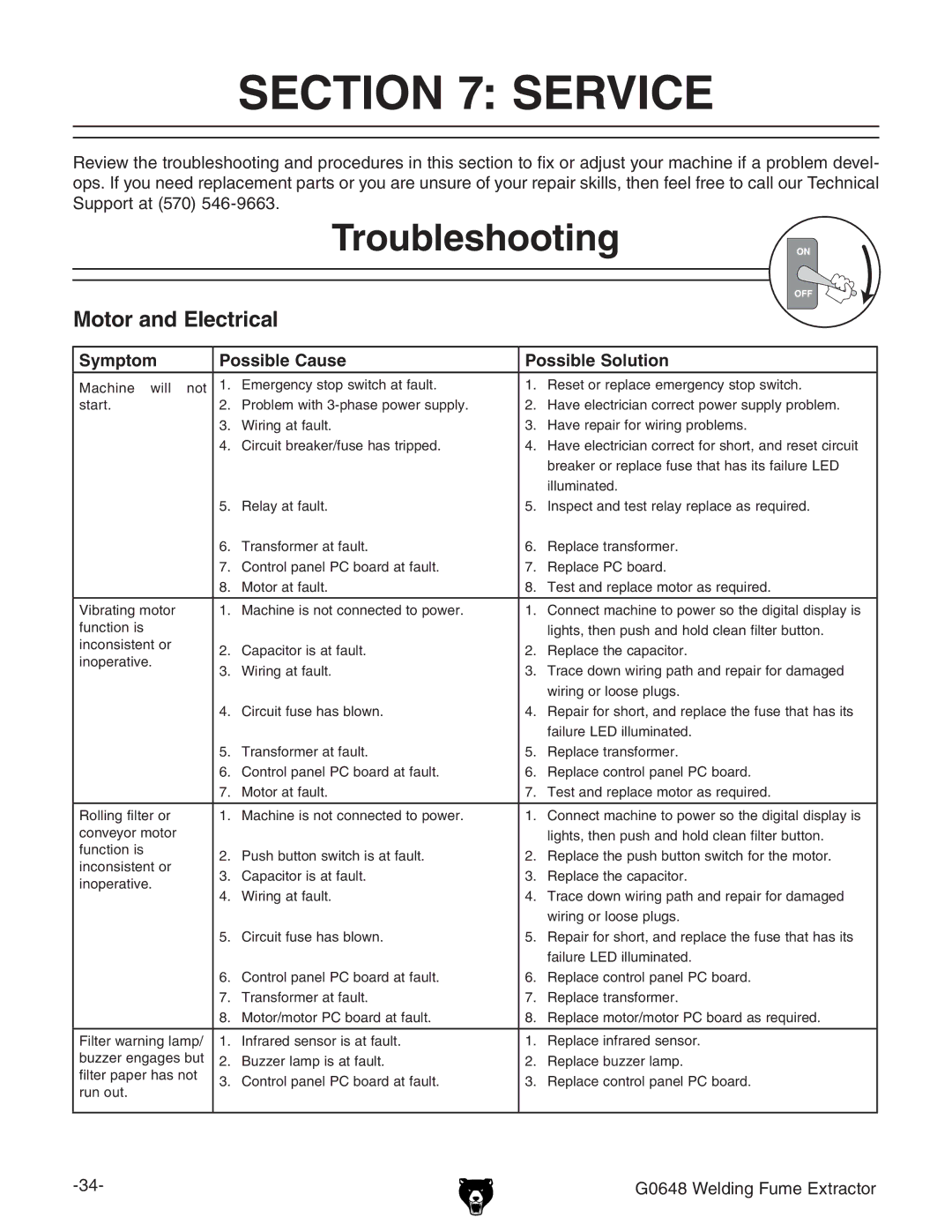

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel- ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

Troubleshooting

Motor and Electrical

Symptom | Possible Cause | Possible Solution | |||

Machine will not | 1. | Emergency stop switch at fault. | 1. | Reset or replace emergency stop switch. | |

start. | 2. | Problem with | 2. | Have electrician correct power supply problem. | |

| 3. | Wiring at fault. | 3. | Have repair for wiring problems. | |

| 4. | Circuit breaker/fuse has tripped. | 4. | Have electrician correct for short, and reset circuit | |

|

|

|

| breaker or replace fuse that has its failure LED | |

|

|

|

| illuminated. | |

| 5. | Relay at fault. | 5. | Inspect and test relay replace as required. | |

| 6. | Transformer at fault. | 6. | Replace transformer. | |

| 7. | Control panel PC board at fault. | 7. | Replace PC board. | |

| 8. | Motor at fault. | 8. | Test and replace motor as required. | |

|

|

|

|

| |

Vibrating motor | 1. | Machine is not connected to power. | 1. | Connect machine to power so the digital display is | |

function is |

|

|

| lights, then push and hold clean filter button. | |

inconsistent or | 2. | Capacitor is at fault. | 2. | Replace the capacitor. | |

inoperative. | |||||

3. | Wiring at fault. | 3. | Trace down wiring path and repair for damaged | ||

| |||||

|

|

|

| wiring or loose plugs. | |

| 4. | Circuit fuse has blown. | 4. | Repair for short, and replace the fuse that has its | |

|

|

|

| failure LED illuminated. | |

| 5. | Transformer at fault. | 5. | Replace transformer. | |

| 6. | Control panel PC board at fault. | 6. | Replace control panel PC board. | |

| 7. | Motor at fault. | 7. | Test and replace motor as required. | |

|

|

|

|

| |

Rolling filter or | 1. | Machine is not connected to power. | 1. | Connect machine to power so the digital display is | |

conveyor motor |

|

|

| lights, then push and hold clean filter button. | |

function is | 2. | Push button switch is at fault. | 2. | Replace the push button switch for the motor. | |

inconsistent or | |||||

3. | Capacitor is at fault. | 3. | Replace the capacitor. | ||

inoperative. | |||||

4. | Wiring at fault. | 4. | Trace down wiring path and repair for damaged | ||

| |||||

|

|

|

| wiring or loose plugs. | |

| 5. | Circuit fuse has blown. | 5. | Repair for short, and replace the fuse that has its | |

|

|

|

| failure LED illuminated. | |

| 6. | Control panel PC board at fault. | 6. | Replace control panel PC board. | |

| 7. | Transformer at fault. | 7. | Replace transformer. | |

| 8. | Motor/motor PC board at fault. | 8. | Replace motor/motor PC board as required. | |

|

|

|

|

| |

Filter warning lamp/ | 1. | Infrared sensor is at fault. | 1. | Replace infrared sensor. | |

buzzer engages but | 2. | Buzzer lamp is at fault. | 2. | Replace buzzer lamp. | |

filter paper has not | 3. | Control panel PC board at fault. | 3. | Replace control panel PC board. | |

run out. | |||||

|

|

|

| ||

|

|

|

|

| |

|

|

| G0648 Welding Fume Extractor | ||