Slag-Screen

Cleaning

Make sure that you clean the slag screen often and inspect for holes or damage. Under correct use, this screen should last for years.

Tools Needed | Qty |

Soft Brass Wire Brush | 1 |

OSHA Approved Respirator | 1 |

Shop Vacuum | 1 |

To perform this procedure: |

|

1.UNPLUG THE MACHINE!

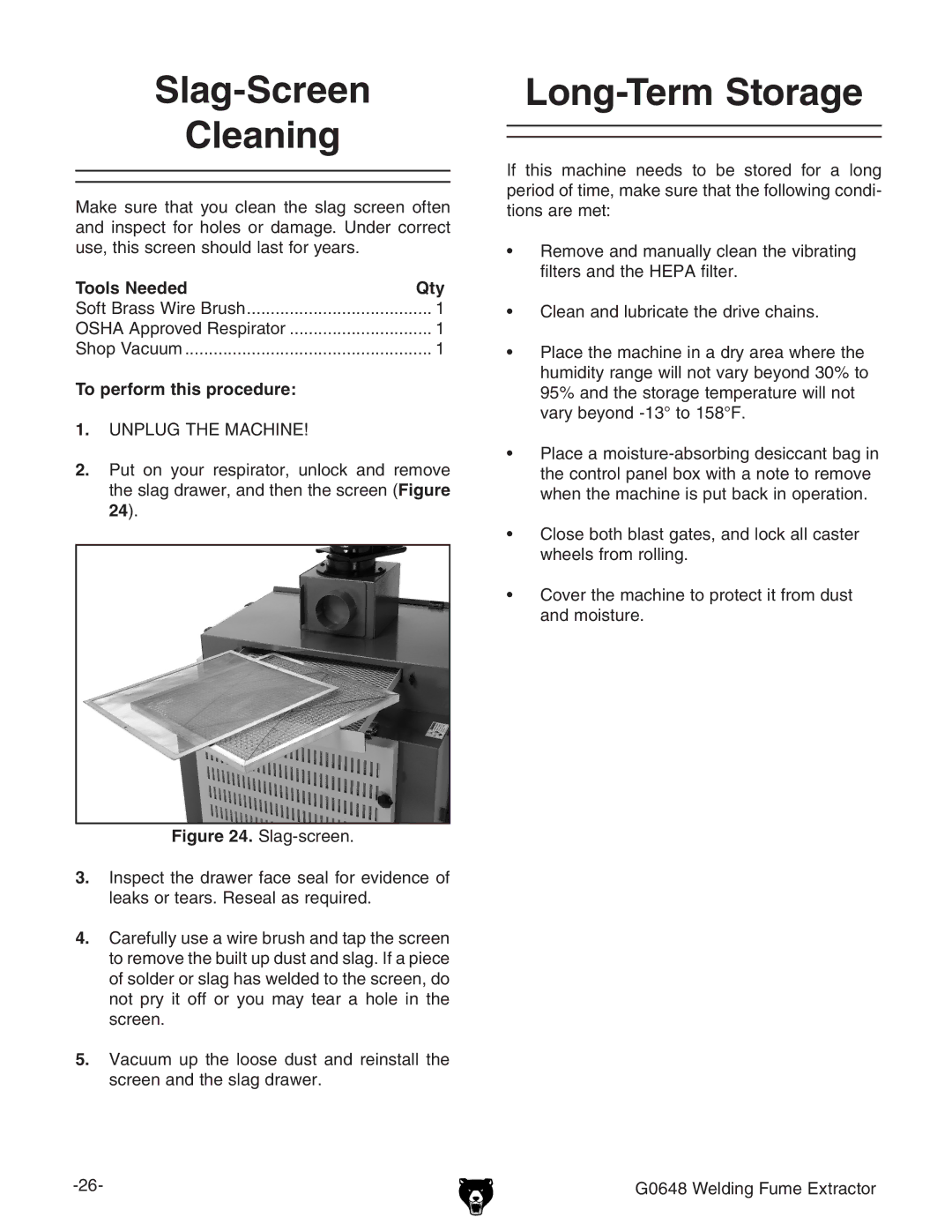

2.Put on your respirator, unlock and remove the slag drawer, and then the screen (Figure 24).

Figure 24. Slag-screen.

3.Inspect the drawer face seal for evidence of leaks or tears. Reseal as required.

4.Carefully use a wire brush and tap the screen to remove the built up dust and slag. If a piece of solder or slag has welded to the screen, do not pry it off or you may tear a hole in the screen.

5.Vacuum up the loose dust and reinstall the screen and the slag drawer.

Long-Term Storage

If this machine needs to be stored for a long period of time, make sure that the following condi- tions are met:

•Remove and manually clean the vibrating filters and the HEPA filter.

•Clean and lubricate the drive chains.

•Place the machine in a dry area where the humidity range will not vary beyond 30% to 95% and the storage temperature will not vary beyond

•Place a

•Close both blast gates, and lock all caster wheels from rolling.

•Cover the machine to protect it from dust and moisture.

G0648 Welding Fume Extractor |