Clean Up |

| Assembly |

|

|

|

|

|

|

The unpainted surfaces are coated with a waxy oil to prevent corrosion during shipment. Remove this protective coating with a solvent cleaner or degreaser, such as shown in Figure 5. For thor- ough cleaning, some parts must be removed.

For optimum performance, clean all moving parts or sliding contact surfaces. Avoid chlo-

Gasoline and petroleum products have low flash points and can explode or cause fire if used to clean machinery. DO NOT use these products to clean the machinery.

Many cleaning solvents are toxic if inhaled. Minimize your risk by only using these products in a well ventilated area.

A great product for removing the waxy shipping grease from your machine during clean up.

Figure 5. Cleaner/degreaser available from

Grizzly.

Model G4173 1⁄8 HP Power Feeder

To correctly position this power feeder on your table top, completely assemble the power feeder first, then refer to Base Mounting on Page 17. With the power feeder unit completely assembled, it will be easier to locate where on the table top you will need to drill your base mounting holes, so you can take advantage of the full range of power feeder swing and adjustments.

To assemble the power feeder:

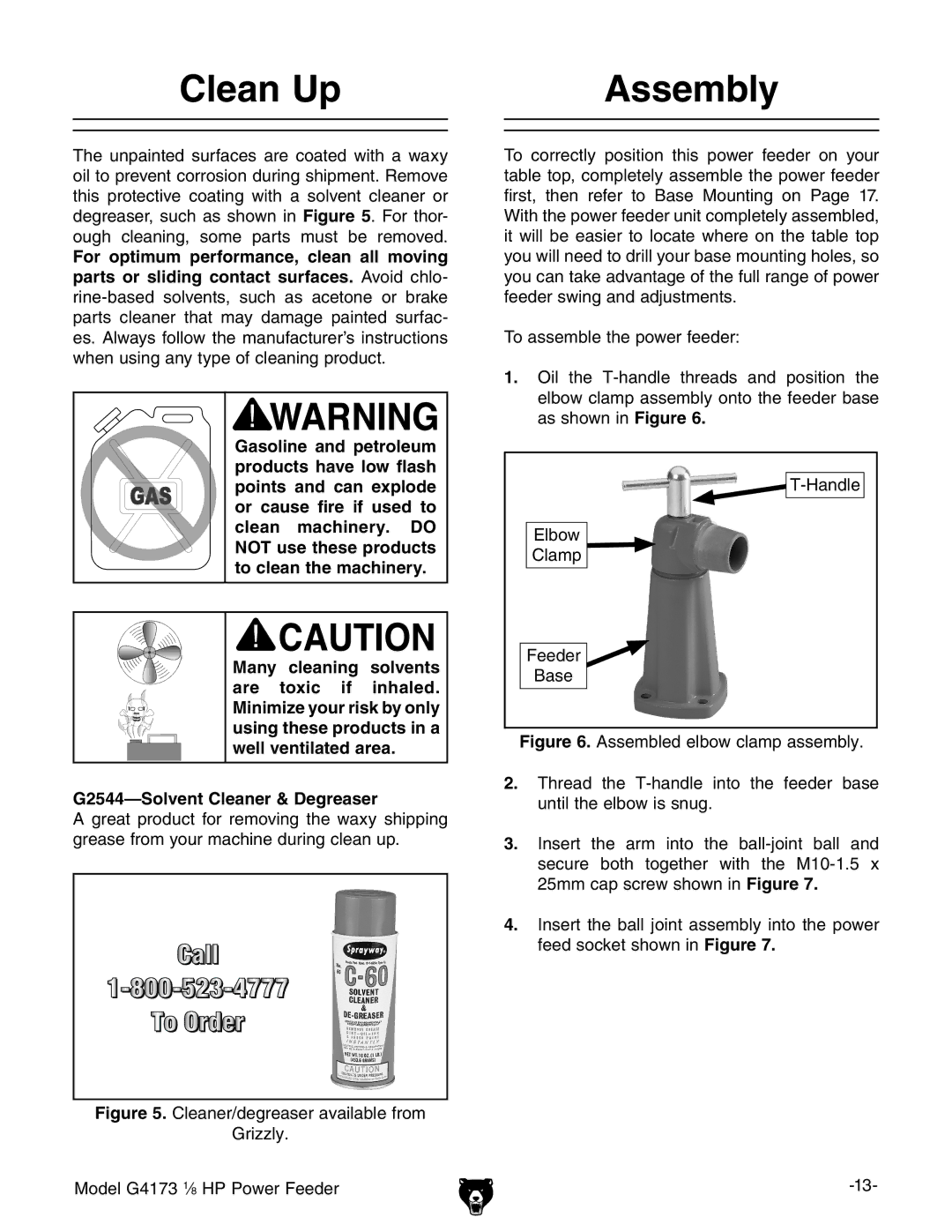

1.Oil the T-handle threads and position the elbow clamp assembly onto the feeder base as shown in Figure 6.

|

Elbow |

Clamp |

Feeder |

Base |