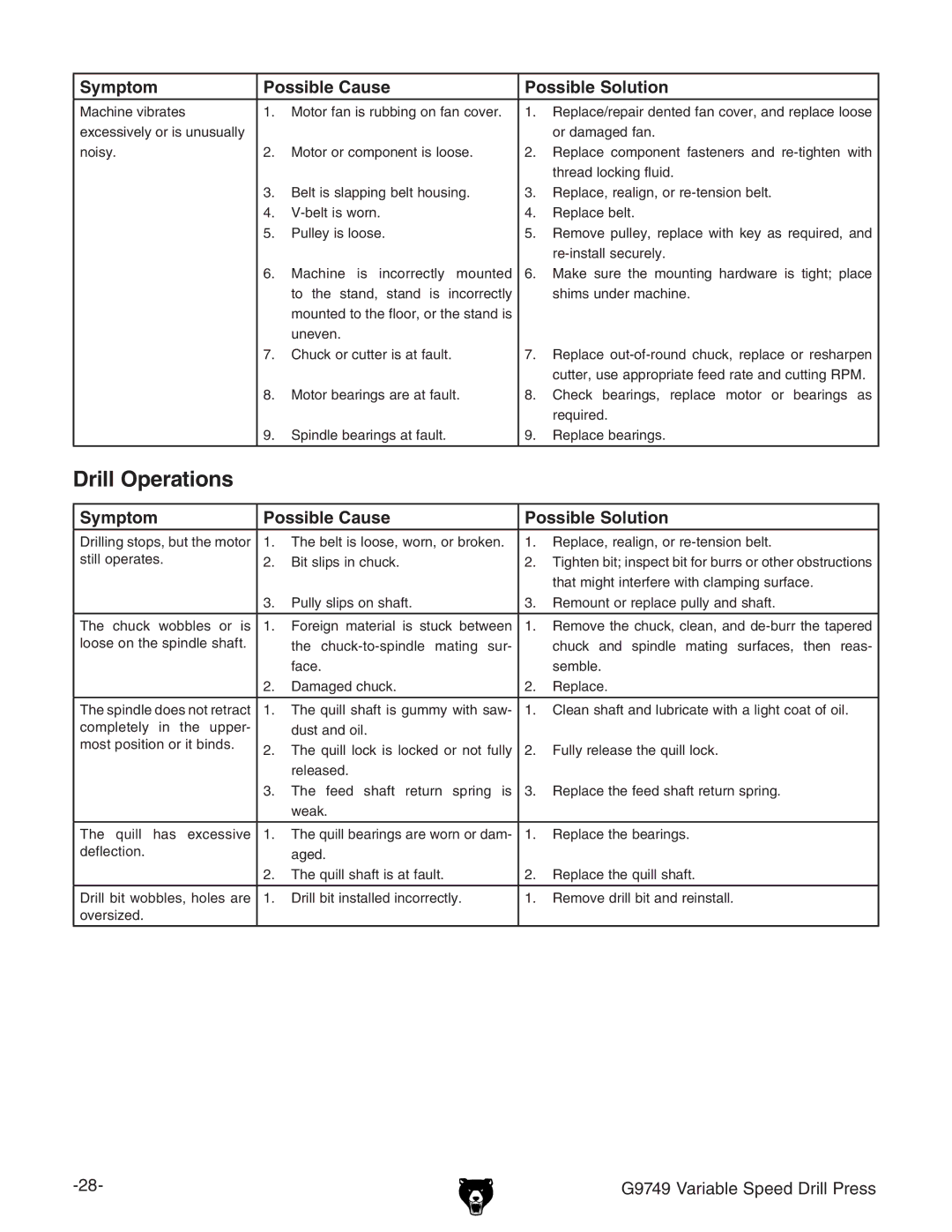

Symptom | Possible Cause | Possible Solution | ||

Machine vibrates | 1. | Motor fan is rubbing on fan cover. | 1. | Replace/repair dented fan cover, and replace loose |

excessively or is unusually |

|

|

| or damaged fan. |

noisy. | 2. | Motor or component is loose. | 2. | Replace component fasteners and |

|

|

|

| thread locking fluid. |

| 3. | Belt is slapping belt housing. | 3. | Replace, realign, or |

| 4. | 4. | Replace belt. | |

| 5. | Pulley is loose. | 5. | Remove pulley, replace with key as required, and |

|

|

|

| |

| 6. | Machine is incorrectly mounted | 6. | Make sure the mounting hardware is tight; place |

|

| to the stand, stand is incorrectly |

| shims under machine. |

|

| mounted to the floor, or the stand is |

|

|

|

| uneven. |

|

|

| 7. | Chuck or cutter is at fault. | 7. | Replace |

|

|

|

| cutter, use appropriate feed rate and cutting RPM. |

| 8. | Motor bearings are at fault. | 8. | Check bearings, replace motor or bearings as |

|

|

|

| required. |

| 9. | Spindle bearings at fault. | 9. | Replace bearings. |

|

|

|

|

|

Drill Operations

Symptom | Possible Cause | Possible Solution | ||

Drilling stops, but the motor | 1. | The belt is loose, worn, or broken. | 1. | Replace, realign, or |

still operates. | 2. | Bit slips in chuck. | 2. | Tighten bit; inspect bit for burrs or other obstructions |

|

|

|

| that might interfere with clamping surface. |

| 3. | Pully slips on shaft. | 3. | Remount or replace pully and shaft. |

|

|

|

|

|

The chuck wobbles or is | 1. | Foreign material is stuck between | 1. | Remove the chuck, clean, and |

loose on the spindle shaft. |

| the |

| chuck and spindle mating surfaces, then reas- |

|

| face. |

| semble. |

| 2. | Damaged chuck. | 2. | Replace. |

|

|

|

|

|

The spindle does not retract | 1. | The quill shaft is gummy with saw- | 1. | Clean shaft and lubricate with a light coat of oil. |

completely in the upper- |

| dust and oil. |

|

|

most position or it binds. | 2. | The quill lock is locked or not fully | 2. | Fully release the quill lock. |

| ||||

|

| released. |

|

|

| 3. | The feed shaft return spring is | 3. | Replace the feed shaft return spring. |

|

| weak. |

|

|

|

|

|

|

|

The quill has excessive | 1. | The quill bearings are worn or dam- | 1. | Replace the bearings. |

deflection. |

| aged. |

|

|

| 2. | The quill shaft is at fault. | 2. | Replace the quill shaft. |

|

|

|

|

|

Drill bit wobbles, holes are | 1. | Drill bit installed incorrectly. | 1. | Remove drill bit and reinstall. |

oversized. |

|

|

|

|

|

|

|

|

|

G9749 Variable Speed Drill Press |