4.Tighten the upper gear clamp to ensure the vent pipe is firmly secured and gas tight.

5.Check that the lower gear clamp is firmly seated, secured and gas tight.

6.As a final check, the vent pipe should be gently moved side to side and vertically. There should be no slippage or movement of the vent pipe within the coupling.

7.Seal around the termination assembly where it passes through the wall, inside and out, with silicone sealant.

WATER | SUFFIX | VENT PIPE | PRESSURE | * VENT | MAXIMUM EQUIVALENT | MINIMUM EQUIVALENT |

HEATER | SWITCH | MATERIAL | ||||

MODEL |

| SIZE | SETTING | (SCHEDULE 40) | VENT LENGTH | VENT LENGTH |

|

|

|

| |||

G/JW40, | NVH, | 50mm (2 in.) | - 0.15 in. w.c. | ABS, PVC**, | 15.2m (50 ft.) + | 0.76m (2.5 ft.) + one 90° |

PVH |

| CPVC | termination elbow | elbow + termination elbow | ||

50 | NVH, | 76mm (3 in.) | - 0.15 in. w.c. | ABS, PVC**, | 24.4m (80 ft.) + | 15.2m (50 ft.) + |

| ||||||

| PVH |

| CPVC | termination elbow | termination elbow | |

G/JW5065 | SNV, | 76mm (3 in.) | - 0.55 in. w.c. | ABS, PVC, | 15.2m (50 ft.) + | 0.91m (3 ft.) + one 90° |

| SPV |

| CPVC | termination elbow | elbow + termination elbow | |

G/JW5065 | LNV | 76mm (3 in.) | - 0.50 in. w.c. | ABS, PVC, | 19.8m (65 ft.) + | 6.9m (20 ft.) + termination |

|

|

| CPVC | termination elbow | elbow |

Notes:

1. Each 50mm (2 in.), 90° long radius elbow is equivalent to 1.5m (5 ft.) of vent length.

2. Each 76mm (3 in.), 90° long radius elbow is equivalent to 2.1m (7 ft.) of vent length.

3. Each 50mm (2 in.), 45°

4. Each 76mm (3 in.), 45° long radius elbow is equivalent to 1.2m (4 ft.) of vent length.

5. Minimum distance between elbows is 150mm (6 in.).

6. Do not mismatch venting materials. *Check local codes to determine which materials are allowed in your area.

7. **Pipe assembly adaptor must be used with PVC venting material (see Figure 14). Table 2 Allowable Vent Lengths and Materials (Vert. and Horiz.).

Water Supply |

|

|

|

|

|

|

|

|

|

|

|

|

|

| lations where the water pressure is high. The pressure- | |||

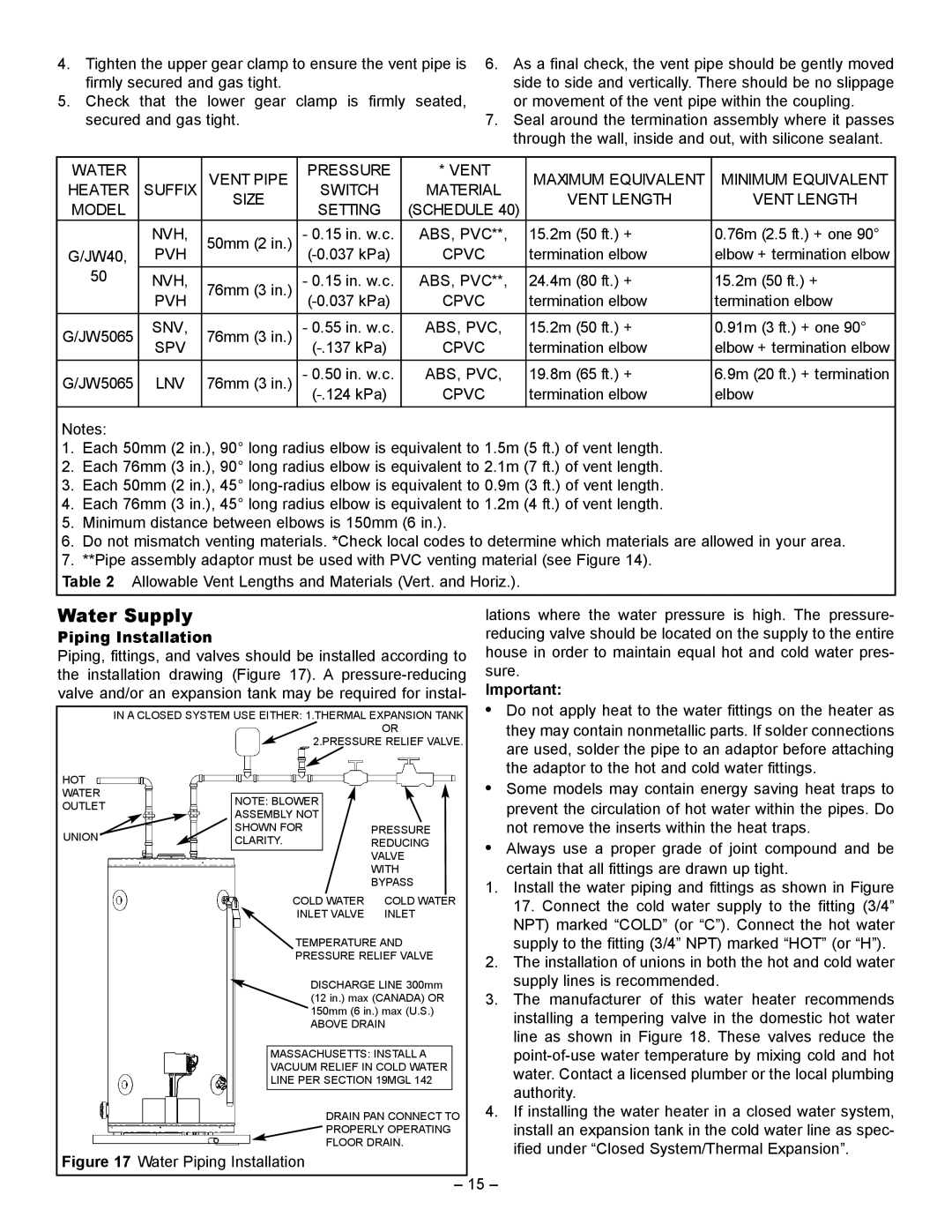

Piping Installation |

|

|

|

|

|

|

|

|

|

|

|

|

|

| reducing valve should be located on the supply to the entire | |||

Piping, fittings, and valves should be installed according to | house in order to maintain equal hot and cold water pres- | |||||||||||||||||

the installation drawing (Figure 17). A | sure. | |||||||||||||||||

valve and/or an expansion tank may be required for instal- | Important: | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| • Do not apply heat to the water fittings on the heater as | ||

|

| IN A CLOSED SYSTEM USE EITHER: 1.THERMAL EXPANSION TANK | ||||||||||||||||

|

|

|

|

|

|

|

|

|

| OR |

| they may contain nonmetallic parts. If solder connections | ||||||

|

|

|

|

|

|

| 2.PRESSURE RELIEF VALVE. |

| are used, solder the pipe to an adaptor before attaching | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| HOT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| the adaptor to the hot and cold water fittings. | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| • Some models may contain energy saving heat traps to | |||

| WATER |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| OUTLET | NOTE: BLOWER |

|

|

|

|

|

|

|

|

|

| prevent the circulation of hot water within the pipes. Do | |||||

| ASSEMBLY NOT |

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

| SHOWN FOR |

|

|

|

|

|

|

|

|

| not remove the inserts within the heat traps. | |||||

|

|

|

| PRESSURE |

| |||||||||||||

| UNION |

|

|

|

|

|

|

|

| |||||||||

|

| CLARITY. |

|

| REDUCING |

|

|

|

|

| • Always use a proper grade of joint compound and be | |||||||

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

| VALVE |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| WITH |

|

|

|

|

|

| certain that all fittings are drawn up tight. | |

|

|

|

|

|

|

|

|

|

| BYPASS |

|

|

|

|

| 1. | Install the water piping and fittings as shown in Figure | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| COLD WATER |

|

| COLD WATER |

|

| 17. Connect the cold water supply to the fitting (3/4” | |||||||

|

|

|

|

|

| INLET VALVE |

|

| INLET |

|

| |||||||

|

|

|

|

|

|

|

|

|

| NPT) marked “COLD” (or “C”). Connect the hot water | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| supply to the fitting (3/4” NPT) marked “HOT” (or “H”). | ||||

|

|

|

|

|

| TEMPERATURE AND |

| |||||||||||

|

|

|

|

|

| PRESSURE RELIEF VALVE |

|

|

|

| 2. | The installation of unions in both the hot and cold water | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| supply lines is recommended. | ||||||

|

|

|

|

|

|

| DISCHARGE LINE 300mm | 3. | ||||||||||

|

|

|

|

|

|

| (12 in.) max (CANADA) OR |

| The manufacturer of this water heater recommends | |||||||||

|

|

|

|

|

|

| 150mm (6 in.) max (U.S.) |

|

| installing a tempering valve in the domestic hot water | ||||||||

|

|

|

|

|

|

| ABOVE DRAIN |

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| line as shown in Figure 18. These valves reduce the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| MASSACHUSETTS: INSTALL A |

|

| ||||||||||||

|

|

|

| VACUUM RELIEF IN COLD WATER |

|

| water. Contact a licensed plumber or the local plumbing | |||||||||||

|

|

|

| LINE PER SECTION 19MGL 142 |

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| authority. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| 4. | If installing the water heater in a closed water system, | |||||

|

|

|

|

|

|

|

| DRAIN PAN CONNECT TO | ||||||||||

|

|

|

|

|

|

|

| PROPERLY OPERATING |

|

| install an expansion tank in the cold water line as spec- | |||||||

|

|

|

|

|

|

|

| FLOOR DRAIN. |

|

| ified under “Closed System/Thermal Expansion”. | |||||||

| Figure 17 Water Piping Installation |

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| – | 15 – |

| ||