|

|

|

|

|

|

|

|

|

|

|

|

|

| DO NOT use any lead based solder in potable water lines. | |||||

|

| FOLLOW THE |

|

|

|

|

| ||||||||||||

|

| TEMPERING |

|

|

|

|

|

|

|

| Use appropriate | ||||||||

|

|

|

|

|

|

| TEMPERED |

| |||||||||||

|

| VALVE MANU- |

|

|

|

|

|

|

| WATER TO |

|

| DO NOT tamper with the gas control/thermostat, igniter, | ||||||

|

| ||||||||||||||||||

|

| FACTURER'S |

|

|

|

|

|

|

| FIXTURE |

|

| |||||||

| INSTRUCTIONS |

|

|

|

|

|

|

|

|

|

| flammable vapour sensor or temperature and pressure | |||||||

|

|

|

|

| |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| relief valve. Tampering voids all warranties. Only qualified | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| service technicians should service these components. | ||

|

|

|

|

|

|

|

|

|

|

| DO NOT use with piping that has been treated with chro- | ||||||||

|

| T&P VALVE |

|

|

|

|

| ||||||||||||

|

| AND DIS- |

|

|

|

|

|

|

|

|

| mates, boiler seal, or other chemicals. | |||||||

|

|

|

|

|

|

|

| ||||||||||||

|

| CHARGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| TEMPERING |

|

| DO NOT add any chemicals to the system piping which will | |||||||||

|

| LINE |

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| VALVE (SET |

|

| contaminate the potable water supply. | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| TO 49°C |

|

| ||||

|

|

|

|

|

|

|

| HOT | |||||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

| WATER |

|

| (120°F)) |

|

| Closed System/Thermal Expansion | |||||

|

|

|

|

|

|

|

| OUTLET |

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| COLD |

|

|

|

|

|

| Periodic discharge of the temperature and pressure relief | ||||||||

|

|

|

|

|

|

|

|

|

| valve may be due to thermal expansion in a closed water | |||||||||

|

|

|

| WATER |

|

|

|

|

|

| |||||||||

|

|

|

| INLET |

|

|

|

|

|

| supply system. The water utility supply meter may contain a | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| check valve, backflow preventer or water | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| valve. This will create a closed water system. During the | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| heating cycle of the water heater, the water expands caus- | ||

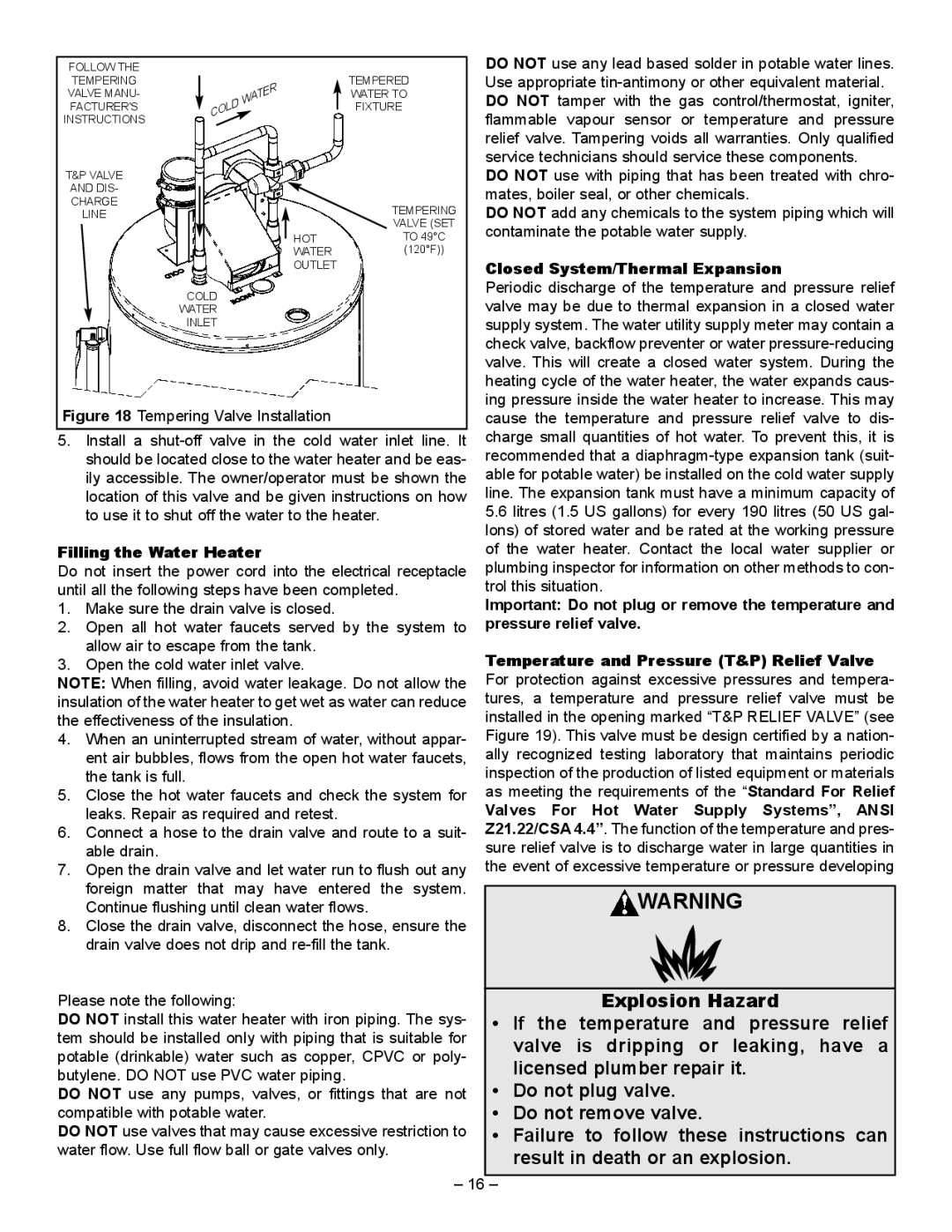

| Figure 18 Tempering Valve Installation |

|

|

|

|

|

| ing pressure inside the water heater to increase. This may | |||||||||||

|

|

|

|

|

|

| cause the temperature and pressure relief valve to dis- | ||||||||||||

5. Install a |

| charge small quantities of hot water. To prevent this, it is | |||||||||||||||||

|

| should be located close to the water heater and be eas- |

| recommended that a | |||||||||||||||

|

| ily accessible. The owner/operator must be shown the |

| able for potable water) be installed on the cold water supply | |||||||||||||||

|

| location of this valve and be given instructions on how |

| line. The expansion tank must have a minimum capacity of | |||||||||||||||

|

| to use it to shut off the water to the heater. |

| 5.6 litres (1.5 US gallons) for every 190 litres (50 US gal- | |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| lons) of stored water and be rated at the working pressure | ||

Filling the Water Heater |

|

|

|

|

|

| of the water heater. Contact the local water supplier or | ||||||||||||

Do not insert the power cord into the electrical receptacle |

| plumbing inspector for information on other methods to con- | |||||||||||||||||

until all the following steps have been completed. |

| trol this situation. | |||||||||||||||||

1. Make sure the drain valve is closed. |

|

|

|

|

|

| Important: Do not plug or remove the temperature and | ||||||||||||

2. Open all hot water faucets served by the system to |

| pressure relief valve. | |||||||||||||||||

|

| allow air to escape from the tank. |

|

|

|

|

|

| Temperature and Pressure (T&P) Relief Valve | ||||||||||

3. Open the cold water inlet valve. |

|

|

|

|

|

| |||||||||||||

NOTE: When filling, avoid water leakage. Do not allow the |

| For protection against excessive pressures and tempera- | |||||||||||||||||

insulation of the water heater to get wet as water can reduce |

| tures, a temperature and pressure relief valve must be | |||||||||||||||||

the effectiveness of the insulation. |

|

|

|

|

|

| installed in the opening marked “T&P RELIEF VALVE” (see | ||||||||||||

4. When an uninterrupted stream of water, without appar- |

| Figure 19). This valve must be design certified by a nation- | |||||||||||||||||

|

| ent air bubbles, flows from the open hot water faucets, |

| ally recognized testing laboratory that maintains periodic | |||||||||||||||

|

| the tank is full. |

|

|

|

|

|

| inspection of the production of listed equipment or materials | ||||||||||

5. Close the hot water faucets and check the system for |

| as meeting the requirements of the “Standard For Relief | |||||||||||||||||

|

| leaks. Repair as required and retest. |

|

|

|

|

|

| Valves For Hot Water Supply Systems”, ANSI | ||||||||||

6. Connect a hose to the drain valve and route to a suit- |

| Z21.22/CSA 4.4”. The function of the temperature and pres- | |||||||||||||||||

|

| able drain. |

|

|

|

|

|

| sure relief valve is to discharge water in large quantities in | ||||||||||

7. Open the drain valve and let water run to flush out any |

| the event of excessive temperature or pressure developing | |||||||||||||||||

|

| foreign matter that may have entered the system. |

|

|

|

| |||||||||||||

|

|

|

|

| WARNING | ||||||||||||||

|

| Continue flushing until clean water flows. |

|

|

| ||||||||||||||

8.Close the drain valve, disconnect the hose, ensure the drain valve does not drip and

Please note the following: |

|

| Explosion Hazard | |

DO NOT install this water heater with iron piping. The sys- | • | If the | temperature | and pressure relief |

tem should be installed only with piping that is suitable for |

| valve | is dripping | or leaking, have a |

potable (drinkable) water such as copper, CPVC or poly- |

| |||

| licensed plumber repair it. | |||

butylene. DO NOT use PVC water piping. | • | |||

DO NOT use any pumps, valves, or fittings that are not | Do not plug valve. |

| ||

compatible with potable water. | • | Do not remove valve. | ||

DO NOT use valves that may cause excessive restriction to | • | Failure | to follow these instructions can | |

water flow. Use full flow ball or gate valves only. |

| result in death or an explosion. | ||

|

| |||

– 16 |

|

|

|

|

– |

|

|

| |