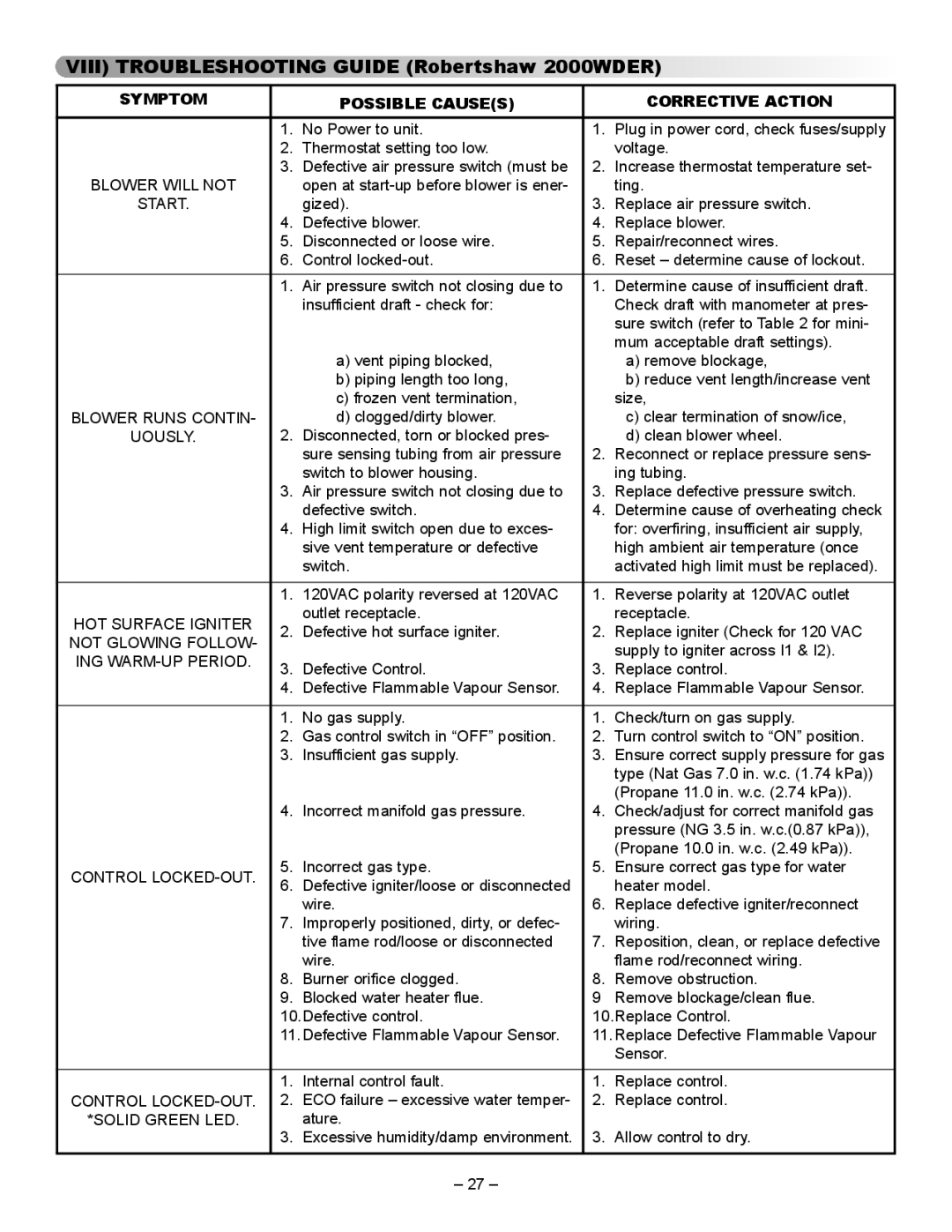

VIII) TROUBLESHOOTING GUIDE (Robertshaw 2000WDER)

SYMPTOM |

| POSSIBLE CAUSE(S) |

| CORRECTIVE ACTION | |

|

|

|

|

| |

| 1. | No Power to unit. | 1. | Plug in power cord, check fuses/supply | |

| 2. | Thermostat setting too low. |

| voltage. | |

| 3. | Defective air pressure switch (must be | 2. | Increase thermostat temperature set- | |

BLOWER WILL NOT |

| open at |

| ting. | |

START. |

| gized). | 3. | Replace air pressure switch. | |

| 4. | Defective blower. | 4. | Replace blower. | |

| 5. | Disconnected or loose wire. | 5. | Repair/reconnect wires. | |

| 6. | Control | 6. | Reset – determine cause of lockout. | |

|

|

|

|

| |

| 1. | Air pressure switch not closing due to | 1. | Determine cause of insufficient draft. | |

|

| insufficient draft - check for: |

| Check draft with manometer at pres- | |

|

|

|

| sure switch (refer to Table 2 for mini- | |

|

|

|

| mum acceptable draft settings). | |

|

| a) vent piping blocked, |

| a) remove blockage, | |

|

| b) piping length too long, |

| b) reduce vent length/increase vent | |

|

| c) frozen vent termination, |

| size, | |

BLOWER RUNS CONTIN- |

| d) clogged/dirty blower. |

| c) clear termination of snow/ice, | |

UOUSLY. | 2. | Disconnected, torn or blocked pres- |

| d) clean blower wheel. | |

|

| sure sensing tubing from air pressure | 2. | Reconnect or replace pressure sens- | |

|

| switch to blower housing. |

| ing tubing. | |

| 3. | Air pressure switch not closing due to | 3. | Replace defective pressure switch. | |

|

| defective switch. | 4. | Determine cause of overheating check | |

| 4. | High limit switch open due to exces- |

| for: overfiring, insufficient air supply, | |

|

| sive vent temperature or defective |

| high ambient air temperature (once | |

|

| switch. |

| activated high limit must be replaced). | |

|

|

|

|

| |

| 1. | 120VAC polarity reversed at 120VAC | 1. | Reverse polarity at 120VAC outlet | |

HOT SURFACE IGNITER |

| outlet receptacle. |

| receptacle. | |

2. | Defective hot surface igniter. | 2. | Replace igniter (Check for 120 VAC | ||

NOT GLOWING FOLLOW- | |||||

|

|

| supply to igniter across I1 & I2). | ||

ING |

|

|

| ||

3. | Defective Control. | 3. | Replace control. | ||

| |||||

| 4. | Defective Flammable Vapour Sensor. | 4. | Replace Flammable Vapour Sensor. | |

|

|

|

|

| |

| 1. | No gas supply. | 1. | Check/turn on gas supply. | |

| 2. | Gas control switch in “OFF” position. | 2. | Turn control switch to “ON” position. | |

| 3. | Insufficient gas supply. | 3. | Ensure correct supply pressure for gas | |

|

|

|

| type (Nat Gas 7.0 in. w.c. (1.74 kPa)) | |

| 4. | Incorrect manifold gas pressure. |

| (Propane 11.0 in. w.c. (2.74 kPa)). | |

| 4. | Check/adjust for correct manifold gas | |||

|

|

|

| pressure (NG 3.5 in. w.c.(0.87 kPa)), | |

| 5. | Incorrect gas type. |

| (Propane 10.0 in. w.c. (2.49 kPa)). | |

CONTROL | 5. | Ensure correct gas type for water | |||

6. | Defective igniter/loose or disconnected |

| heater model. | ||

|

| ||||

|

| wire. | 6. | Replace defective igniter/reconnect | |

| 7. | Improperly positioned, dirty, or defec- |

| wiring. | |

|

| tive flame rod/loose or disconnected | 7. | Reposition, clean, or replace defective | |

|

| wire. |

| flame rod/reconnect wiring. | |

| 8. | Burner orifice clogged. | 8. | Remove obstruction. | |

| 9. | Blocked water heater flue. | 9 | Remove blockage/clean flue. | |

| 10.Defective control. | 10.Replace Control. | |||

| 11. Defective Flammable Vapour Sensor. | 11. Replace Defective Flammable Vapour | |||

|

|

|

| Sensor. | |

|

|

|

|

| |

| 1. | Internal control fault. | 1. | Replace control. | |

CONTROL | 2. | ECO failure – excessive water temper- | 2. | Replace control. | |

*SOLID GREEN LED. |

| ature. |

|

| |

| 3. | Excessive humidity/damp environment. | 3. | Allow control to dry. | |

|

|

|

|

| |

– 27 –