Diagnostic Repair Manual

Replacement Parts

Safety

Table of Contents

57-59

Magnetism

Electromagnetic Fields

Electromagnetic Induction

More Sophisticated AC Generator

Simple AC Generator

Generator Operating Diagram

Field Boost

Generator AC Connection System

Line Breakers 120 VAC only

Connection for 120/240 VAC Dual Voltage

LIC Grit or Abrasive to Clean Slip Rings

Rotor Assembly

General

Battery Charge Components

Brush Holder

Excitation Circuit Components

Voltage Regulator

Adjust POT LED

Adjustment Procedure

162

Control Panel Components

Control Panel Component Identification

Insulation Resistance Testers

Cleaning the Generator

Effects of Dirt and Moisture

Drying the Generator

Stator SHORT-TO-GROUND Tests

Brushing and Vacuum Cleaning

Stator Insulation Resistance

Cloth or Compressed AIR

Megohmmeter

Testing Rotor Insulation

Measuring DC Voltage

Meters

VOM

Measuring AC Voltage

Measuring AC Frequency

Measuring Current

Measuring Resistance

Ohms LAW

Electrical Units

Introduction

Operational Analysis

Circuit CONDITION- OFF

Circuit CONDITION- PRE-HEAT

Circuit CONDITION- Cranking

Circuit CONDITION-RUNNING

Circuit CONDITION- Shutdown

Circuit CONDITION- Fault Shutdowns

Engine Control Circuit Board

Battery

Adding Water

Effects of Temperature

Checking Battery State of Charge

Charging a Battery

Starter Contactor & Motor

Preheat Switch

START/STOP Switch

AMP Fuse

Glow Plugs

Engine Governor

Fuel Injection Pump

Fuel NOZZLES/INJECTORS

Overspeed Protection

LOW OIL Pressure Switch High Coolant Temperature Switch

Adapter LOW OIL Pressure Switch

Engine Protective Devices

Troubleshooting Flowcharts

Troubleshooting Flowcharts

Problem 3 No Battery Charge Output

Troubleshooting Flowcharts

Troubleshooting Flowcharts

Troubleshooting Flowcharts

Troubleshooting Flowcharts

Troubleshooting Flowcharts

Test 1- Check NO-LOAD Voltage Frequency

Test 2 Check & Adjust

Test 4- Fixed Excitation TEST/ROTOR AMP Draw

Test 3- Test Excitation Circuit Breaker

Set a VOM to its Rx1 scale

Test 5- Wire Continuity

Re-connect Wire 11 and Wire 22 to the Voltage Regulator

Test 6- Check Field Boost

Model QP75D

Test 7 Test Stator DPE Winding

184W

Test 8- Check Sensing Leads / Power Windings

Test 9- Check Brush Leads

159W

Test 11- Check Rotor Assembly

Tance Tests Procedure

Test 10 Check Brushes & Slip Rings

Test 14- Check Load Watts & Amperage

Test 15 Check Battery Charge Output

Test 12 Check Main Circuit Breaker

Test 13- Check Load Voltage Frequency

Test 16 Check Battery Charge Rectifier

Battery Charge Rectifier BCR is a full wave rectifier

Short to Ground

Test 20- Check Fuel Pump

Test 19- Test PRE-HEAT Switch

Set a VOM to read battery voltage 12 VDC

Test 18 TRY Cranking the Engine

Test 21- Check 14 AMP Fuse

Test 22- Check Battery & Cables

Test 23- Check Power Supply to Circuit Board

Disconnect the connector from the wires of the fuel pump

Not Activated

Test 24 Check START-STOP Switch

Test 26- Test Starter Contactor

Test 27 Check Starter Motor

Conditions Affecting Starter Motor Performance

Measuring Current

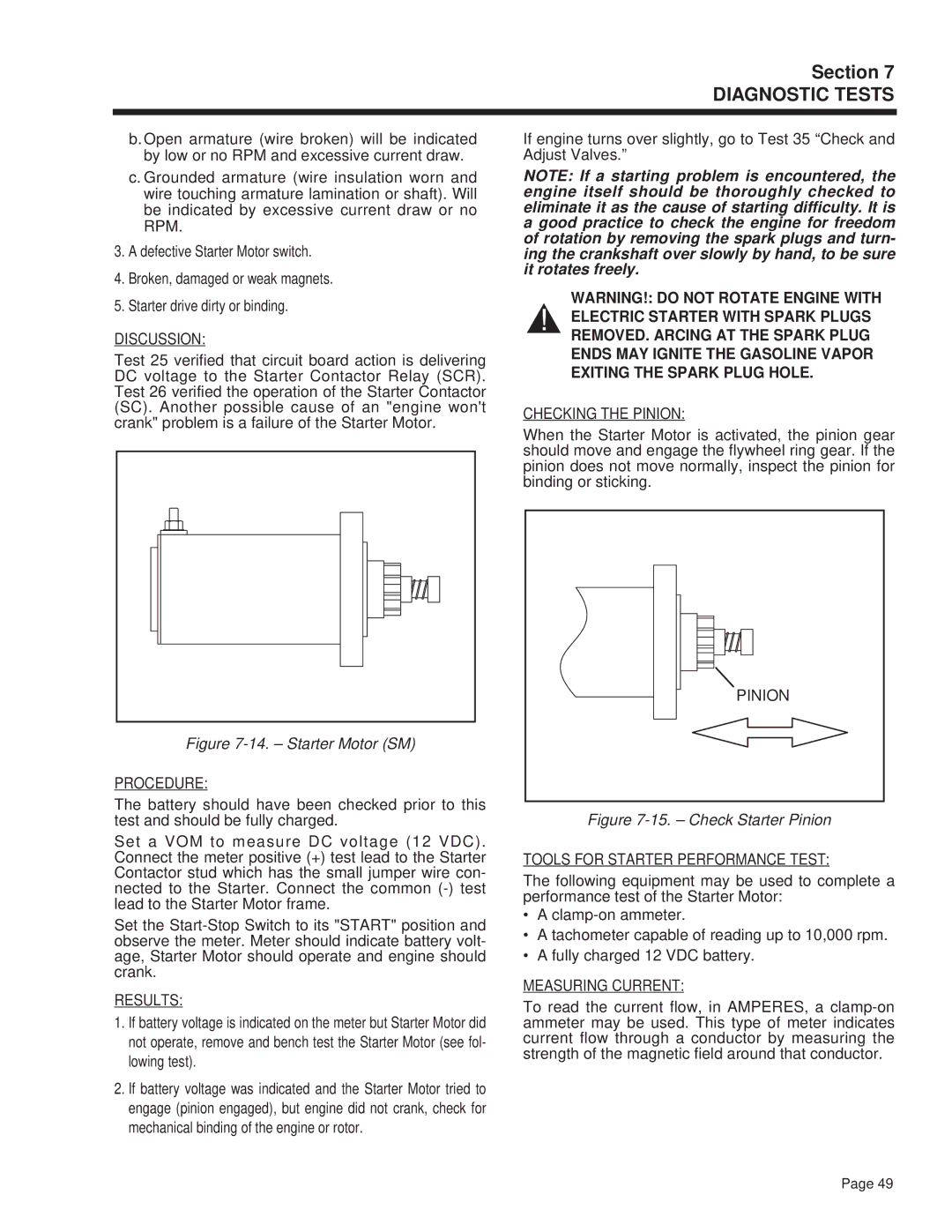

Checking the Pinion

Pinion

Tools for Starter Performance Test

Starter motor test bracket may be made as shown in Figure

Testing Starter Motor

Tachometer

Test Bracket

Test 28- Check Fuel Supply

Test 29 Check Wire 14 Power Supply

Test 30 Check Wire

If Wire 18 checks GOOD, proceed to Problem 8 Section

Test 32- Test Preheat Contactor

Test 33- Test Glow Plugs

Test 34- Test D1 Diode

Test 35- Check Valve Adjustment

Remove the valve cover from engine Disconnect the battery

Test 36- Fuel Injector Pump

Repeat Steps 1 through 8 on remaining cylinder

If fuel is noted, proceed to next step in flowchart

Adjust the regulated pressure on the gauge to 80 psi

Down Test / Compression Test

Test 38 Check OIL Pressure Switch

Test 40- Test Water Temperature Switch

Test 39- Check Circuit Board for Ground

Test 43 Check Wire 15 for Short to Ground

If continuity is measure, replace the switch

Components for Short to Ground

Major Disassembly

Belt Tensioning

RE-ASSEMBLY

FAN Belt

Line Corner UP Between 5˚ to 10˚

Section Exploded Views / Part Numbers

Bearing Carrier, Front

Rotor Assembly

Stator Assembly

Flywheel Assembly

Base Frame Drawing No D2357-A

Slide Latch Flush

Door, Service Rear

Door, Service Front

Base Frame Weldment

Enclosure Drawing No D2358-D

Decal, Battery +

Cover, Access Lift

Cover, Access Electrical

Gasket, Electrical Access

Views / Part

Cover Plate, Scroll Weldment

25 26

Wire Assembly #

Assembly, Potted Regulator

Assembly Marine Control Board

Rectifier, Battery Charging

Intake and Exhaust System Drawing No D2362-B

Hose, Air Inlet

Exhaust Gasket

Chamber Air Intake

Air Filter

Views / Part Numbers

Wire Assembly, Black #4 Ground

Fuel Pump Assembly

Boot, Battery Cable

Cable, Battery

Customer Controls Assembly Drawing No D2364-D

Boot, Circuit Breaker

Start / Stop Switch

Switch, Pushbutton Spst

Boot / Nut / Preheat Switch

Gear

Camshaft Assembly

Camshaft Gear

KEY

2630

Liter Diesel Cylinder Head Drawing No D2794

Liter Diesel Crankshaft, Piston and Flywheel Drawing No -B

OIL Pump Cover

Idler Gear Assembly

Spring

Thrust Washer

Exhaust Rocker ARM

Rocker ARM Assembly

Includes ALL Components Shown below

Intake Rocker ARM

Liter Diesel Injector Pump Drawing No -C

Tank Return Model 04270 To Injection Pump To Fuel Pump

27 25 19 18

HOUSING, Timing Gear

3114

Liter Diesel Water Pump Drawing No

Charts

Generator Specifications

Engine Specifications

Type Quietpact Model

ROTOR/STATOR Resistance Values

Page

Data

Data

Electrical Data

C4945

Schematic Drawing No C4945-A Model

C4946-A

Electrical

Sheet 2

OF4996 REV. O