Section 3

INSULATION RESISTANCE TESTS

DANGER!: DO NOT ATTEMPT TO WORK WITH SOLVENTS IN ANY ENCLOSED AREA. PROVIDE ADEQUATE VENTILATION WHEN WORKING WITH SOLVENTS. WITHOUT ADE- QUATE VENTILATION, FIRE, EXPLOSION OR HEALTH HAZARDS MAY EXIST . WEAR EYE PROTECTION. WEAR RUBBER GLOVES TO PROTECT THE HANDS.

CLOTH OR COMPRESSED AIR:

For small parts or when dry dirt is to be removed, a dry cloth may be satisfactory. Wipe the parts clean, then use low pressure air at 30 psi (206 Kpa) to blow dust away.

BRUSHING AND VACUUM CLEANING:

Brushing with a soft bristle brush followed by vacuum cleaning is a good method of removing dust and dirt. Use the soft brush to loosen the dirt, then remove it with the vacuum.

STATOR INSULATION RESISTANCE

GENERAL:

Insulation resistance is a measure of the integrity of the insulating materials that separate electrical wind- ings from the generator's steel core. This resistance can degrade over time due to the presence of conta- minants, dust, dirt, grease and especially moisture.

The normal insulation resistance for generator wind- ings is on the order of “millions of ohms” or “megohms”.

When checking the insulation resistance, follow the tester manufacturer's instructions carefully. Do NOT exceed the applied voltages recommended in this manual. Do NOT apply the voltage longer than one

(1) second.

CAUTION!: DO NOT connect the

STATOR SHORT-TO-GROUND TESTS:

See Figure

1.Disconnect and isolate all Stator leads as follows:

a.Disconnect sensing leads 11 and 22 from the voltage regulator.

b.Disconnect excitation winding lead No. 6 from the voltage regulator.

c.Disconnect excitation lead No. 2 from the excitation circuit breaker (CB2).

d.Disconnect battery charge winding leads No. 66 and 77 from the battery charge recti- fier (BCR).

e.Disconnect battery charge winding lead No. 55 from the battery charge resistor (R1).

f.At the main circuit breakers, disconnect sta- tor power leads No. 11P and 33.

g.At the ground stud (GND5), disconnect Stator power leads No. 22 and 33.

2.When all leads have been disconnected as outlined in Step 1 above, test for a

a.Connect the terminal ends of all Stator leads together (11, 22, 33, 44, 2,6, 55, 66, 77).

b.Follow the tester manufacturer's instructions carefully. Connect the tester leads across all Stator leads and to frame ground on the Stator can. Apply a voltage of 1500 volts. Do NOT apply voltage longer than one (1) second.

If the test indicates a breakdown in insulation, the Stator should be cleaned, dried and

TEST BETWEEN ISOLATED WINDINGS:

1.Follow the tester manufacturer's instructions carefully. Connect the tester test leads across Stator leads No. 11 (POWER) and No. 2. Apply a voltage of 1500 volts- DO NOT EXCEED ONE SECOND.

2 ![]()

![]() 6

6 ![]()

![]()

11 ![]()

![]()

![]()

![]() 11

11

22

22

33

44

55 ![]()

![]()

66 ![]()

![]() 77

77 ![]()

![]()

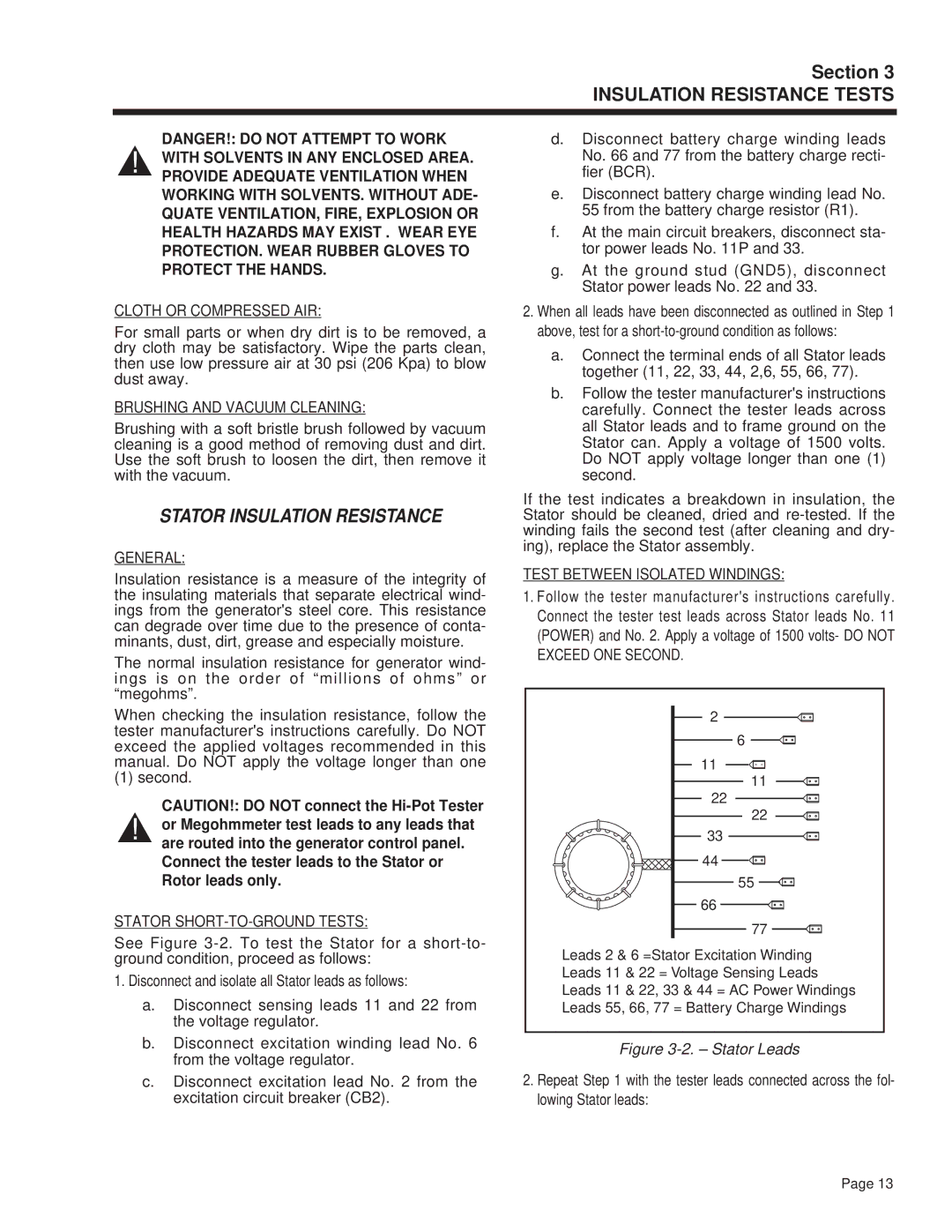

Leads 2 & 6 =Stator Excitation Winding Leads 11 & 22 = Voltage Sensing Leads Leads 11 & 22, 33 & 44 = AC Power Windings Leads 55, 66, 77 = Battery Charge Windings

Figure 3-2. – Stator Leads

2.Repeat Step 1 with the tester leads connected across the fol- lowing Stator leads:

Page 13