Diagnostic Repair Manual

Diagnostic Repair Manual

Electrical Formulas

Stator Winding Resistance Values / Rotor Resistance

Engine

Fuel Consumption

Mounting Dimensions

Specifications

Major Features

Part General Information

Serial Number

Introduction

Item Number

Prepackaged Transfer Switches

Transfer Switch / Load Center

Selecting a Location

Grounding the Generator

Prepackaged Installation Basics Part

System Control Interconnections

Power Source and Load Lines

Fuel Requirements

General

Meters

Visual Inspection

VOM

Measuring AC Voltage

Measuring Resistance

Measuring AC Frequency

Measuring Current

Ohms LAW

Electrical Units

Ampere

Volt

Stator Insulation Resistance Test

Insulation Resistance

Megohmmeter

Test Between Windings

Testing ALL Stator Windings to Ground

Drying the Generator

Cleaning the Generator

Rotor Insulation Resistance Test

LOW OIL Pressure Shutdown

High OIL Temperature Shutdown

Overspeed Shutdown

Overcrank Shutdown

OFF Position

Control Panel

Manual Position

Auto position

To Select Automatic Operation

SET Exercise Switch

Manual Transfer to Standby Manual Startup

Protection Systems

Manual Shutdown and Retransfer Back to Utility

Automatic Operating Sequences

Automatic Operating Parameters

SEQ. Condition Action SENSOR, Timer or Other

Part AC Generators

ENGINE-GENERATOR Drive System

Rotor Assembly

AC Generator

Brush Holder and Brushes

Stator Assembly

Other AC Generator Components

Excitation Circuit Breaker

Main Line Circuit Breaker

Voltage Regulator

Field Boost Circuit

Rotor Residual Magnetism

Field Boost

Operation

Troubleshooting Flowcharts

Troubleshooting Flowcharts Part

Section

Section

Procedure

Safety

Test 1- Check Main Circuit Breaker

Discussion

If a high voltage is indicated, go on to Test

Test 2- Check AC Output Voltage

Test 3- Test Excitation Circuit Breaker

Set VOM to AC volts

Test 4- Fixed Excitation Test Rotor AMP Draw Test

Test 6 Check Field Boost

Test 5 Wire Continuity

Test 7 Testing the Stator with a VOM

Set VOM to the Rx1 scale

Test 8 Resistance Check Rotor Circuit

If continuity was measured in steps 5 and 6 proceed to step

Remove wire 4 from the voltage regulator

Test 9 Check Brushes Slip Rings

Test 12 Check and Adjust Engine Governor

Test 10 Test Rotor Assembly

Test 11 Check AC Output Frequency

Start the engine, let it stabilize and warm up at no-load

Loosen the governor clamp bolt Figure

Procedure 7KW Units

Test 15 Check for Overload Condition

Test 13 Check and Adjust Voltage Regulator

Test 14 Check Voltage Frequency Under Load

Test 16 Check Engine Condition

Part Type Prepackaged Transfer Switches

Enclosure

Transfer Mechanism

Limit Switches XA1 and XB1

Utility Closing Coil C1

Standby Closing Coil C2

Neutral LUG

Transfer Relay

Manual Transfer Handle

Terminal Block

Utility 1

Fuse Holder

Terminals 23

Fuses F1, F2

Operational Analysis

Wiring Diagram and Schematic

Utility Source Voltage Available

Utility Source Power Available

Utility Source Voltage Failure

Generator Power Available, Waiting to Transfer

Transfer Action to Standby Position

Transfer to Standby

Generator Powering Load

Utility Restored, Generator Still Providing Output to Load

Utility Restored

Utility Restored, Transfer Relay De-energized

Utility RESTORED, Transfer Switch DE-ENERGIZED

Utility RESTORED, Retransfer Back to Utility

Transfer Switch in Utility

Transfer Switch in Utility

Introduction to Troubleshooting

Troubleshooting Flow Charts Part

If the generator has been shut down, proceed as follows

Test 21- Check Voltage AT Terminal Lugs E1, E2

Test 22 Check Voltage AT Standby Closing Coil C2

Test 23 Test Transfer Relay TR

Test 24- Check Manual Transfer Switch Operation

Now, connect the VOM test leads across Relay Terminals 1

Continuity Results

Test 25- Test Limit Switch XB1

Test 27- Check Voltage AT Terminal Lugs N1, N2

WIRING/CONNECTIONS

PROCEDURE/RESULTS

Test 29- Check Voltage AT Utility Closing Coil C1

Utility 2 Terminals

Test 30 Check Fuses F1 and F2

Test 31 Test Limit Switch XA1

Test 34 Check N1 and N2 Wiring

Test 33 Continuity Test of Wiring C2

Set the AUTO-OFF-MANUAL switch to the OFF position

See Test 32, Step

Test 35 Check Transformer TX

Transformer TX

Part DC Control

Transformer TX

Terminal Strip / Interconnection

Circuit Board

Utility 1 and Utility

Description and Components

AMP Fuse

AUTO-OFF-MANUAL Switch

Control Panel Component Identification

Circuit Condition Utility Source Voltage Available

Operational Analysis

Circuit Condition Initial Dropout of Utility Source Voltage

Initial Dropout Utility Source Voltage

Section

Utility Voltage Dropout Engine Cranking

Section

Circuit Condition Engine Startup and Running

Engine Startup and Running

Section

Initial Transfer to Standby Source

Section

Circuit Condition Utility Voltage Restored

Utility Voltage Restored / RE Transfer to Utility

Section

Circuit Condition Retransfer to Utility and Engine Shutdown

Engine Shutdown

Operational Analysis

Troubleshooting Flow Charts Part

Troubleshooting Flow Charts

Section

Section

Section

Section

Section

Test 42 TRY a Manual Start

Test 41 Check Position of AUTO-OFF Manual Switch

Test 43- Test AUTO-OFF-MANUAL Switch

Set a VOM to measure DC voltage

Replace AUTO-OFF-MANUAL switch, if defective

Inspect Battery Cables

Test 46- Check Battery

Test Battery State of Charge

Test 45- Check 15 AMP Fuse

Test Battery Condition

Test 47 Check Wire 56 Voltage

If battery voltage is not indicated in , go to Test

Test 48- Test Starter Contactor Relay V-TWIN only

Starter Contactor Relay

Test 49- Test Starter Contactor

Shorted, open or grounded armature

Test 50- Test Starter Motor

Conditions Affecting Starter Motor Performance

Checking the Pinion

Tools for Starter Performance Test

Tachometer

Measuring Current

Test Bracket

Remove Starter Motor

Testing Starter Motor

Test 51 Check Fuel Supply Pressure

Testing Starter Motor Performance

Disconnect Wire 14 at the Fuel Solenoid FS

Test 53 Check Circuit Board Wire Output

Set the AUTO-OFF-MANUAL switch to OFF

Test 52 Test Fuel Solenoid

Test 55 Check for Ignition Spark

Test 54 Check Fuel Solenoid

If sparking occurs but engine still wont start, go to Test

Test 56 Check Spark Plugs

Test 57- Check Engine Compression

If ignition spark still has not occurred, proceed to Test

Test 58 Check Shutdown Wire

Test 59 Check and Adjust Ignition Magnetos

Setting Ignition Magneto Armature Air Gap

Check engine crankcase oil level

Test 60- Check OIL Pressure Switch Wire

With oil level correct, try starting the engine

Do the following

Switch terminals

Test 61- Check High OIL Temperature Switch

Replace switch if it fails the test

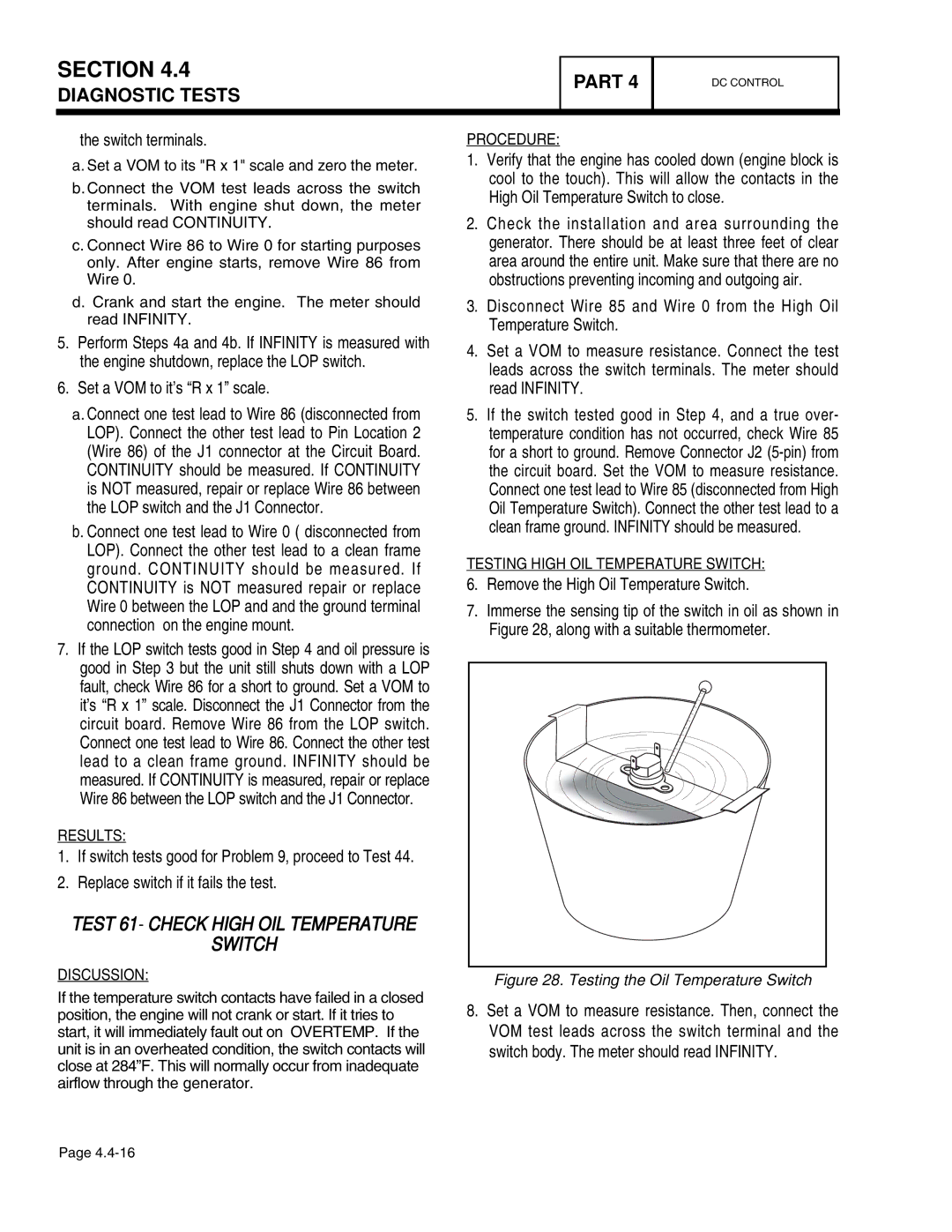

Remove the High Oil Temperature Switch

Test 63 Check Fuel Regulator

Test 62 Check and Adjust Valves

Procedure Intake and Exhaust

Test 64 Check Battery Charge Output

Test 65 Check Transformer TX Voltage Output

Test 66 Check AC Voltage AT Battery Charger

Set a VOM to measure AC voltage

If voltage was not measured in , go to Test

BCR

Test 68 Check Battery Charge Winding Harness

Set VOM to measure frequency 63 HZ should be measured

Test 69 Check Battery Charger Wiring

Test 70 Check Engine RUN Winding

AT the Circuit Board

Test 73 Test SET Exercise Switch

Test 71 Check N1 and N2 Voltage

Test 76 Check Cranking and Running Circuits

Test 74 Check Remote Start Wiring If Equipped

Test 75 Check Battery Voltage Circuit

Continuity

Test 77 Test Exercise Function

Part Operational Tests

Electrical Checks

Manual Transfer Switch Operation

Type Transfer Switches

Generator Tests Under Load

Checking Automatic Operation

Setting the Exercise Timer

Verify that the AUTO-OFF-MANUAL switch is set to Auto

Part Disassembly

STATOR/ROTOR/ENGINE Removal

Major Disassembly

Remove door

Major Disassembly

Reverse the previous steps to re-assemble

Front Engine Access

Follow Stator/Rotor/Engine removal procedures, Steps

Part Electrical Data

Model

Part SCHEMATIC, 7 KW Home Standby

Model 4456-0

Part SCHEMATIC, 12 & 15 KW Home Standby

Drawing #0D9013-C 1

Part Wiring DIAGRAM, 7 KW Home Standby

Drawing #0D9014-B 1

Drawing #0D9014-B 2

Model 4456-1

Part Wiring DIAGRAM, 12 & 15 KW Home Standby

Drawing #0D8501-B 1

Drawing #0D8501-B 2

Part

Electrical Data

Part

Page

Page

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxxxxxxxxxxx Part

Procedure

Section