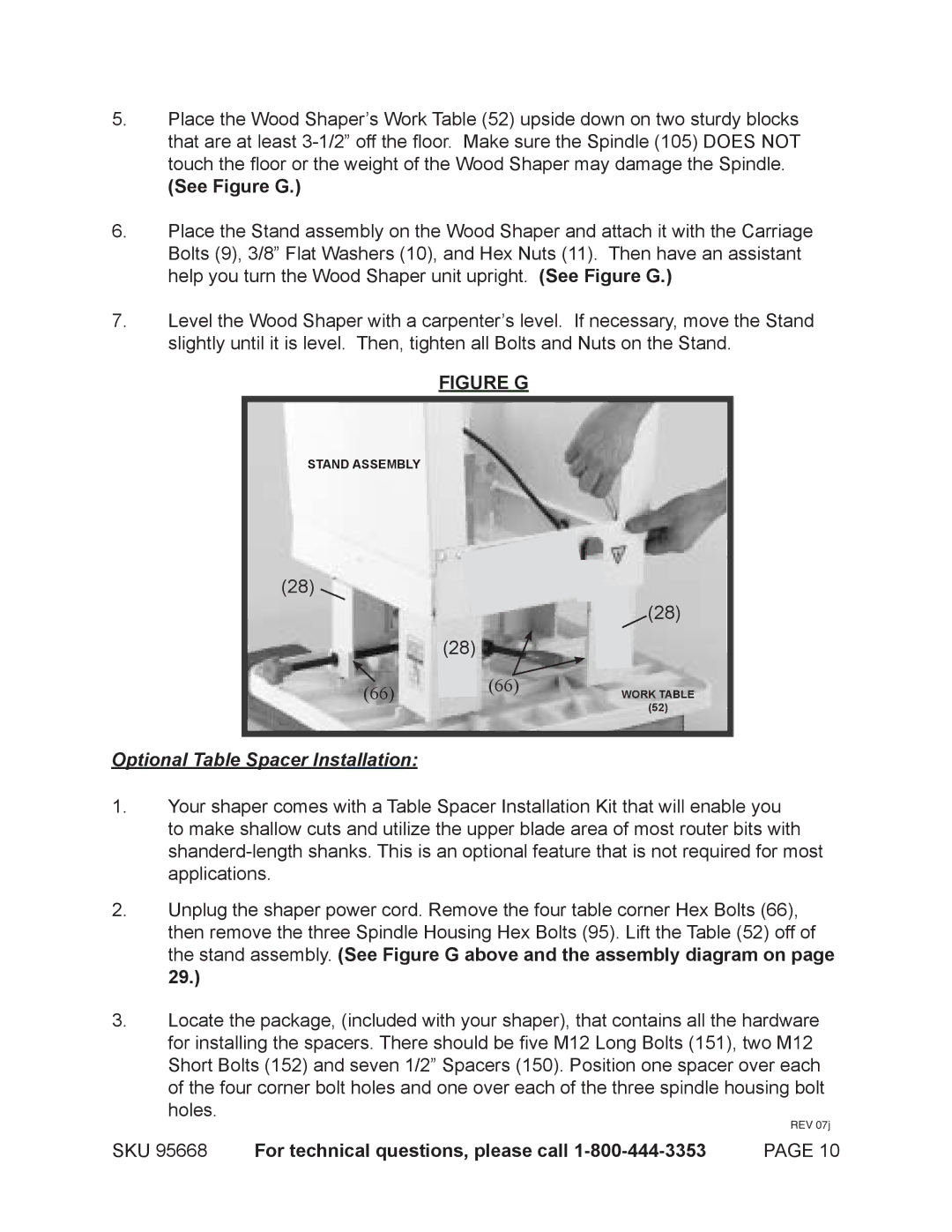

5.Place the Wood Shaper’s Work Table (52) upside down on two sturdy blocks that are at least

(See Figure G.)

6.Place the Stand assembly on the Wood Shaper and attach it with the Carriage

Bolts (9), 3/8” Flat Washers (10), and Hex Nuts (11). Then have an assistant help you turn the Wood Shaper unit upright. (See Figure G.)

7.Level the Wood Shaper with a carpenter’s level. If necessary, move the Stand slightly until it is level. Then, tighten all Bolts and Nuts on the Stand.

FIGURE G

STAND ASSEMBLY

(28)

|

| (28) |

| (28) |

|

(66) | (66) | WORK TABLE |

| ||

|

| (52) |

Optional Table Spacer Installation:

1.Your shaper comes with a Table Spacer Installation Kit that will enable you to make shallow cuts and utilize the upper blade area of most router bits with

2.Unplug the shaper power cord. Remove the four table corner Hex Bolts (66), then remove the three Spindle Housing Hex Bolts (95). Lift the Table (52) off of the stand assembly. (See Figure G above and the assembly diagram on page 29.)

3.Locate the package, (included with your shaper), that contains all the hardware for installing the spacers. There should be five M12 Long Bolts (151), two M12 Short Bolts (152) and seven 1/2” Spacers (150). Position one spacer over each of the four corner bolt holes and one over each of the three spindle housing bolt holes.

REV 07j

SKU 95668 | For technical questions, please call | PAGE 10 |