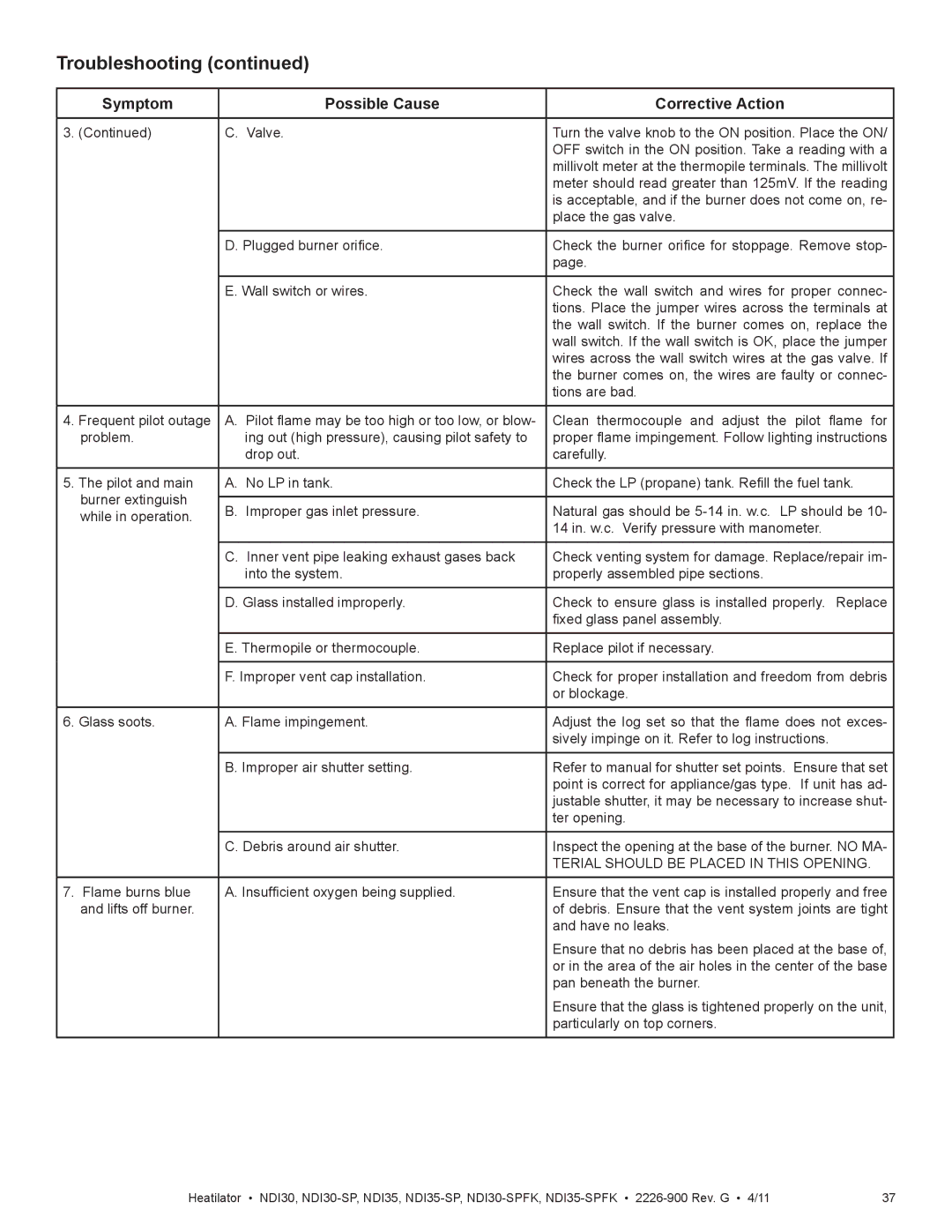

Troubleshooting (continued)

Symptom | Possible Cause | Corrective Action | |

|

|

| |

3. (Continued) | C. Valve. | Turn the valve knob to the ON position. Place the ON/ | |

|

| OFF switch in the ON position. Take a reading with a | |

|

| millivolt meter at the thermopile terminals. The millivolt | |

|

| meter should read greater than 125mV. If the reading | |

|

| is acceptable, and if the burner does not come on, re- | |

|

| place the gas valve. | |

|

|

| |

| D. Plugged burner orifi ce. | Check the burner orifi ce for stoppage. Remove stop- | |

|

| page. | |

|

|

| |

| E. Wall switch or wires. | Check the wall switch and wires for proper connec- | |

|

| tions. Place the jumper wires across the terminals at | |

|

| the wall switch. If the burner comes on, replace the | |

|

| wall switch. If the wall switch is OK, place the jumper | |

|

| wires across the wall switch wires at the gas valve. If | |

|

| the burner comes on, the wires are faulty or connec- | |

|

| tions are bad. | |

|

|

| |

4. Frequent pilot outage | A. Pilot fl ame may be too high or too low, or blow- | Clean thermocouple and adjust the pilot fl ame for | |

problem. | ing out (high pressure), causing pilot safety to | proper fl ame impingement. Follow lighting instructions | |

| drop out. | carefully. | |

|

|

| |

5. The pilot and main | A. No LP in tank. | Check the LP (propane) tank. Refi ll the fuel tank. | |

burner extinguish |

|

| |

B. Improper gas inlet pressure. | Natural gas should be | ||

while in operation. | |||

| 14 in. w.c. Verify pressure with manometer. | ||

|

| ||

|

|

| |

| C. Inner vent pipe leaking exhaust gases back | Check venting system for damage. Replace/repair im- | |

| into the system. | properly assembled pipe sections. | |

|

|

| |

| D. Glass installed improperly. | Check to ensure glass is installed properly. Replace | |

|

| fi xed glass panel assembly. | |

|

|

| |

| E. Thermopile or thermocouple. | Replace pilot if necessary. | |

|

|

| |

| F. Improper vent cap installation. | Check for proper installation and freedom from debris | |

|

| or blockage. | |

|

|

| |

6. Glass soots. | A. Flame impingement. | Adjust the log set so that the fl ame does not exces- | |

|

| sively impinge on it. Refer to log instructions. | |

|

|

| |

| B. Improper air shutter setting. | Refer to manual for shutter set points. Ensure that set | |

|

| point is correct for appliance/gas type. If unit has ad- | |

|

| justable shutter, it may be necessary to increase shut- | |

|

| ter opening. | |

|

|

| |

| C. Debris around air shutter. | Inspect the opening at the base of the burner. NO MA- | |

|

| TERIAL SHOULD BE PLACED IN THIS OPENING. | |

|

|

| |

7. Flame burns blue | A. Insuffi cient oxygen being supplied. | Ensure that the vent cap is installed properly and free | |

and lifts off burner. |

| of debris. Ensure that the vent system joints are tight | |

|

| and have no leaks. | |

|

| Ensure that no debris has been placed at the base of, | |

|

| or in the area of the air holes in the center of the base | |

|

| pan beneath the burner. | |

|

| Ensure that the glass is tightened properly on the unit, | |

|

| particularly on top corners. | |

|

|

|

Heatilator • NDI30, | 37 |