English

11. Inspect the rotating stability of the saw blade.

For precise cutting, rotate the saw blade and check for deflection to confirm that the blade is not noticeably unstable; otherwise vibrations might occur and cause an accident.

BEFORE CUTTING

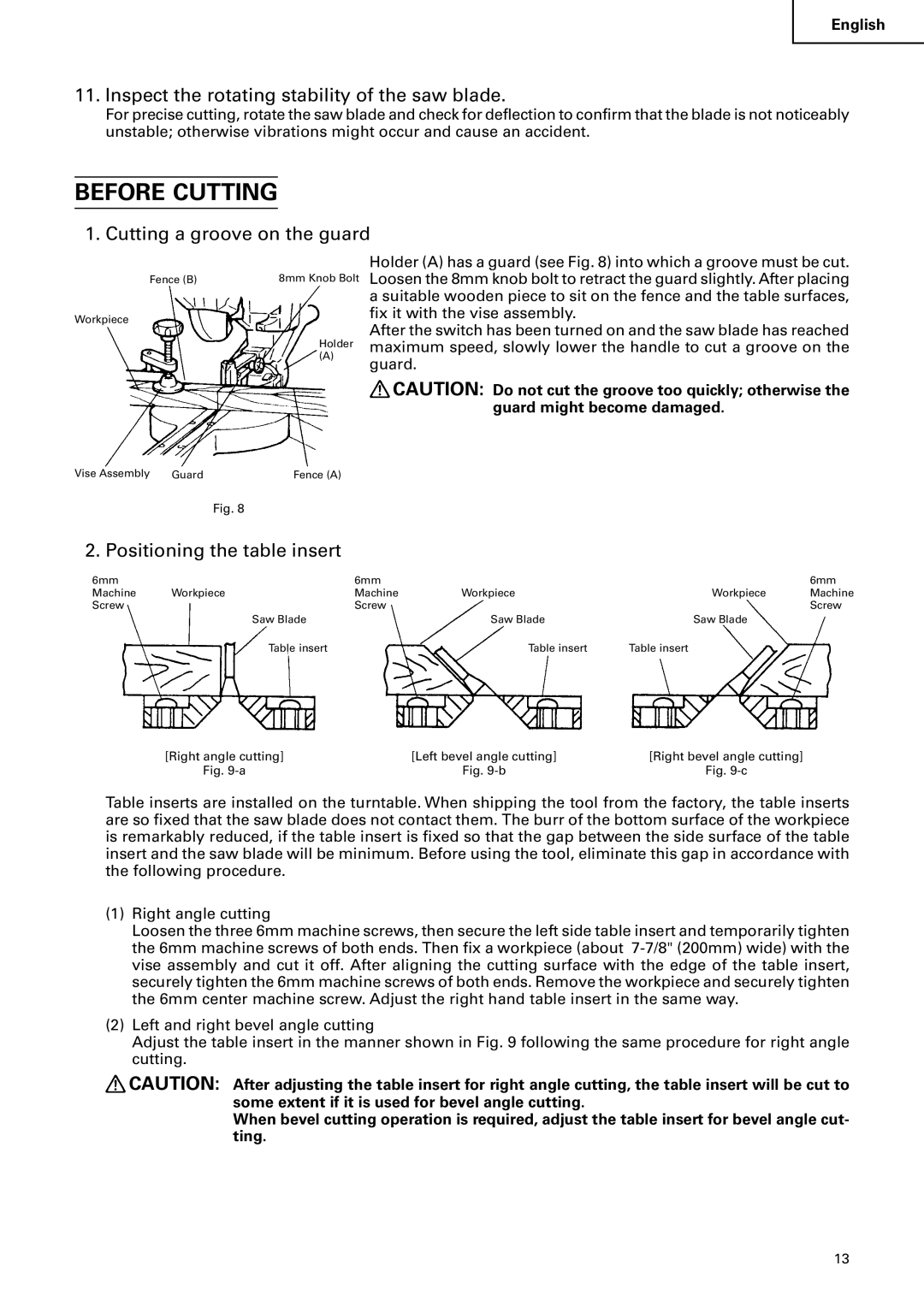

1. Cutting a groove on the guard

Fence (B) | 8mm Knob Bolt |

Workpiece

Holder

(A)

Holder (A) has a guard (see Fig. 8) into which a groove must be cut. Loosen the 8mm knob bolt to retract the guard slightly. After placing a suitable wooden piece to sit on the fence and the table surfaces, fix it with the vise assembly.

After the switch has been turned on and the saw blade has reached maximum speed, slowly lower the handle to cut a groove on the guard.

![]() CAUTION: Do not cut the groove too quickly; otherwise the

CAUTION: Do not cut the groove too quickly; otherwise the

guard might become damaged.

Vise Assembly | Guard | Fence (A) |

|

| Fig. 8 |

2. Positioning the table insert

6mm |

|

|

|

|

|

| 6mm |

|

|

|

|

|

|

|

|

| 6mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Machine | Workpiece |

|

|

|

| Machine |

| Workpiece |

|

|

|

| Workpiece | Machine | |||

Screw |

| Sa |

| Blade | Screw |

| Sa |

| Blade |

|

|

|

| Saw Blade | Screw | ||

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

| w |

| w |

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| Table | insert | Table | insert |

| ||

|

|

|

| Table | insert |

|

|

| |||||||||

[Right angle cutting] | [Left bevel angle cutting] | [Right bevel angle cutting] |

Fig. | Fig. | Fig. |

Table inserts are installed on the turntable. When shipping the tool from the factory, the table inserts are so fixed that the saw blade does not contact them. The burr of the bottom surface of the workpiece is remarkably reduced, if the table insert is fixed so that the gap between the side surface of the table insert and the saw blade will be minimum. Before using the tool, eliminate this gap in accordance with the following procedure.

(1)Right angle cutting

Loosen the three 6mm machine screws, then secure the left side table insert and temporarily tighten the 6mm machine screws of both ends. Then fix a workpiece (about

(2)Left and right bevel angle cutting

Adjust the table insert in the manner shown in Fig. 9 following the same procedure for right angle cutting.

![]() CAUTION: After adjusting the table insert for right angle cutting, the table insert will be cut to some extent if it is used for bevel angle cutting.

CAUTION: After adjusting the table insert for right angle cutting, the table insert will be cut to some extent if it is used for bevel angle cutting.

When bevel cutting operation is required, adjust the table insert for bevel angle cut- ting.

13