Caution

7.2Mounting of the drive

1.Mount the drive with four

2.Mounting holes (A1,A2,B1,B2,B3) are available for mounting.(See figure 8.3)

It is recommended that the 4 holes, (A1,A2 or B1,B3 on figure 8.3), be used for mounting to keep the proper space between mounting holes.

3.Maximum penetration of the screw is 3.8 mm.

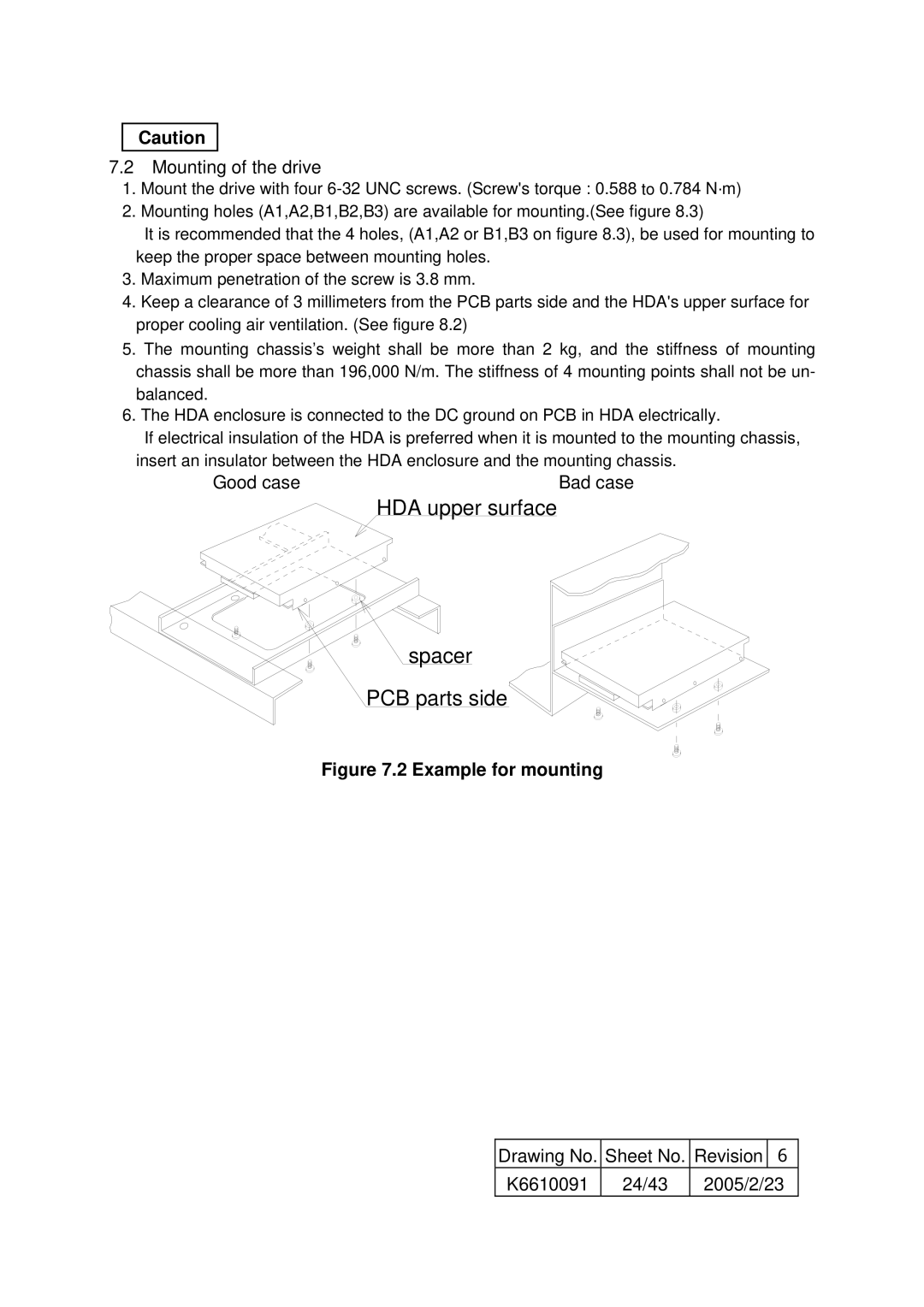

4.Keep a clearance of 3 millimeters from the PCB parts side and the HDA's upper surface for proper cooling air ventilation. (See figure 8.2)

5.The mounting chassis’s weight shall be more than 2 kg, and the stiffness of mounting chassis shall be more than 196,000 N/m. The stiffness of 4 mounting points shall not be un- balanced.

6.The HDA enclosure is connected to the DC ground on PCB in HDA electrically.

If electrical insulation of the HDA is preferred when it is mounted to the mounting chassis, insert an insulator between the HDA enclosure and the mounting chassis.

Good case | Bad case |

HDA upper surface

spacer

PCB parts side

Figure 7.2 Example for mounting

Drawing No. Sheet No. Revision 6 | ||

K6610091 | 24/43 | 2005/2/23 |