English

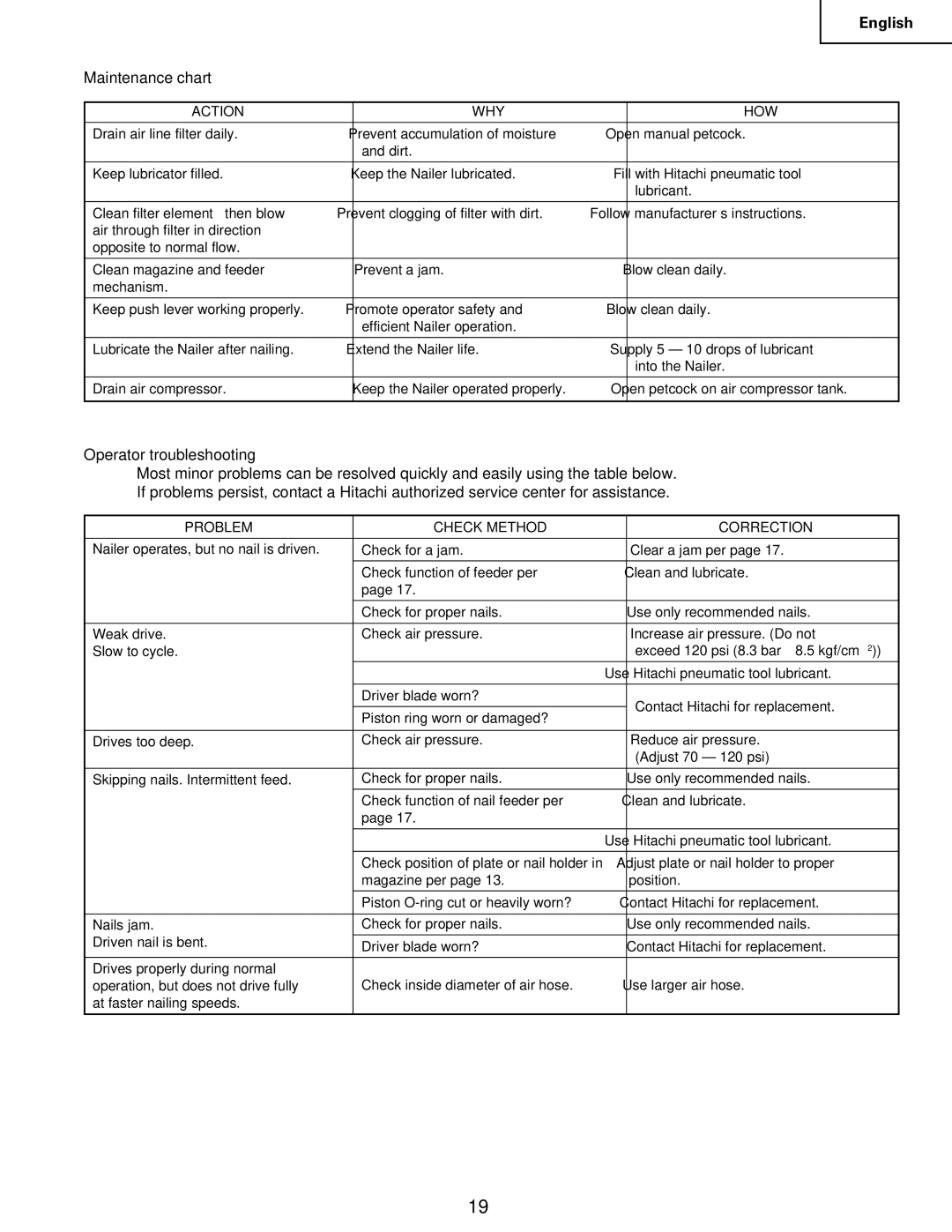

Maintenance chart

ACTION | WHY | HOW |

|

|

|

Drain air line filter daily. | Prevent accumulation of moisture | Open manual petcock. |

| and dirt. |

|

|

|

|

Keep lubricator filled. | Keep the Nailer lubricated. | Fill with Hitachi pneumatic tool |

|

| lubricant. |

|

|

|

Clean filter element — then blow | Prevent clogging of filter with dirt. | Follow manufacturer’s instructions. |

air through filter in direction |

|

|

opposite to normal flow. |

|

|

|

|

|

Clean magazine and feeder | Prevent a jam. | Blow clean daily. |

mechanism. |

|

|

|

|

|

Keep push lever working properly. | Promote operator safety and | Blow clean daily. |

| efficient Nailer operation. |

|

|

|

|

Lubricate the Nailer after nailing. | Extend the Nailer life. | Supply 5 – 10 drops of lubricant |

|

| into the Nailer. |

|

|

|

Drain air compressor. | Keep the Nailer operated properly. | Open petcock on air compressor tank. |

|

|

|

Operator troubleshooting

Most minor problems can be resolved quickly and easily using the table below. If problems persist, contact a Hitachi authorized service center for assistance.

PROBLEM | CHECK METHOD | CORRECTION |

|

|

|

Nailer operates, but no nail is driven. | Check for a jam. | Clear a jam per page 17. |

|

|

|

| Check function of feeder per | Clean and lubricate. |

| page 17. |

|

|

|

|

| Check for proper nails. | Use only recommended nails. |

|

|

|

Weak drive. | Check air pressure. | Increase air pressure. (Do not |

Slow to cycle. |

| exceed 120 psi (8.3 bar 8.5 kgf/cm2)) |

| Use Hitachi pneumatic tool lubricant. | |

|

|

|

| Driver blade worn? | Contact Hitachi for replacement. |

|

| |

| Piston ring worn or damaged? | |

|

| |

|

|

|

Drives too deep. | Check air pressure. | Reduce air pressure. |

|

| (Adjust 70 – 120 psi) |

|

|

|

Skipping nails. Intermittent feed. | Check for proper nails. | Use only recommended nails. |

| Check function of nail feeder per | Clean and lubricate. |

| page 17. |

|

|

|

|

| Use Hitachi pneumatic tool lubricant. | |

|

|

|

| Check position of plate or nail holder in | Adjust plate or nail holder to proper |

| magazine per page 13. | position. |

|

|

|

| Piston | Contact Hitachi for replacement. |

|

|

|

Nails jam. | Check for proper nails. | Use only recommended nails. |

Driven nail is bent. | Driver blade worn? | Contact Hitachi for replacement. |

| ||

|

|

|

Drives properly during normal | Check inside diameter of air hose. | Use larger air hose. |

operation, but does not drive fully | ||

at faster nailing speeds. |

|

|

|

|

|

— 19 —