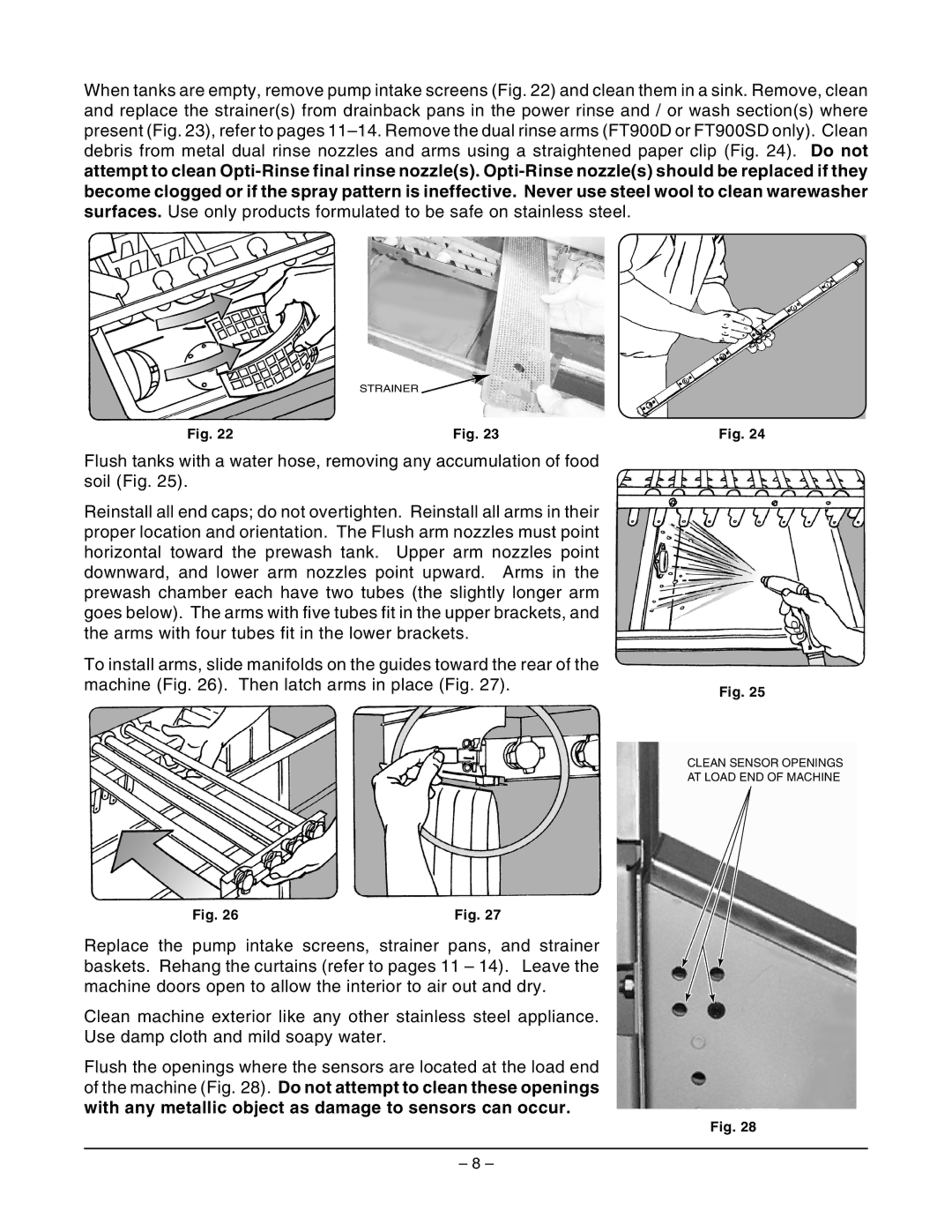

When tanks are empty, remove pump intake screens (Fig. 22) and clean them in a sink. Remove, clean and replace the strainer(s) from drainback pans in the power rinse and / or wash section(s) where present (Fig. 23), refer to pages

STRAINER ![]()

Fig. 22 | Fig. 23 |

Flush tanks with a water hose, removing any accumulation of food soil (Fig. 25).

Reinstall all end caps; do not overtighten. Reinstall all arms in their proper location and orientation. The Flush arm nozzles must point horizontal toward the prewash tank. Upper arm nozzles point downward, and lower arm nozzles point upward. Arms in the prewash chamber each have two tubes (the slightly longer arm goes below). The arms with five tubes fit in the upper brackets, and the arms with four tubes fit in the lower brackets.

To install arms, slide manifolds on the guides toward the rear of the machine (Fig. 26). Then latch arms in place (Fig. 27).

Fig. 26 | Fig. 27 |

Replace the pump intake screens, strainer pans, and strainer baskets. Rehang the curtains (refer to pages 11 – 14). Leave the machine doors open to allow the interior to air out and dry.

Clean machine exterior like any other stainless steel appliance. Use damp cloth and mild soapy water.

Flush the openings where the sensors are located at the load end of the machine (Fig. 28). Do not attempt to clean these openings with any metallic object as damage to sensors can occur.

Fig. 24

Fig. 25

CLEAN SENSOR OPENINGS AT LOAD END OF MACHINE

Fig. 28

– 8 –