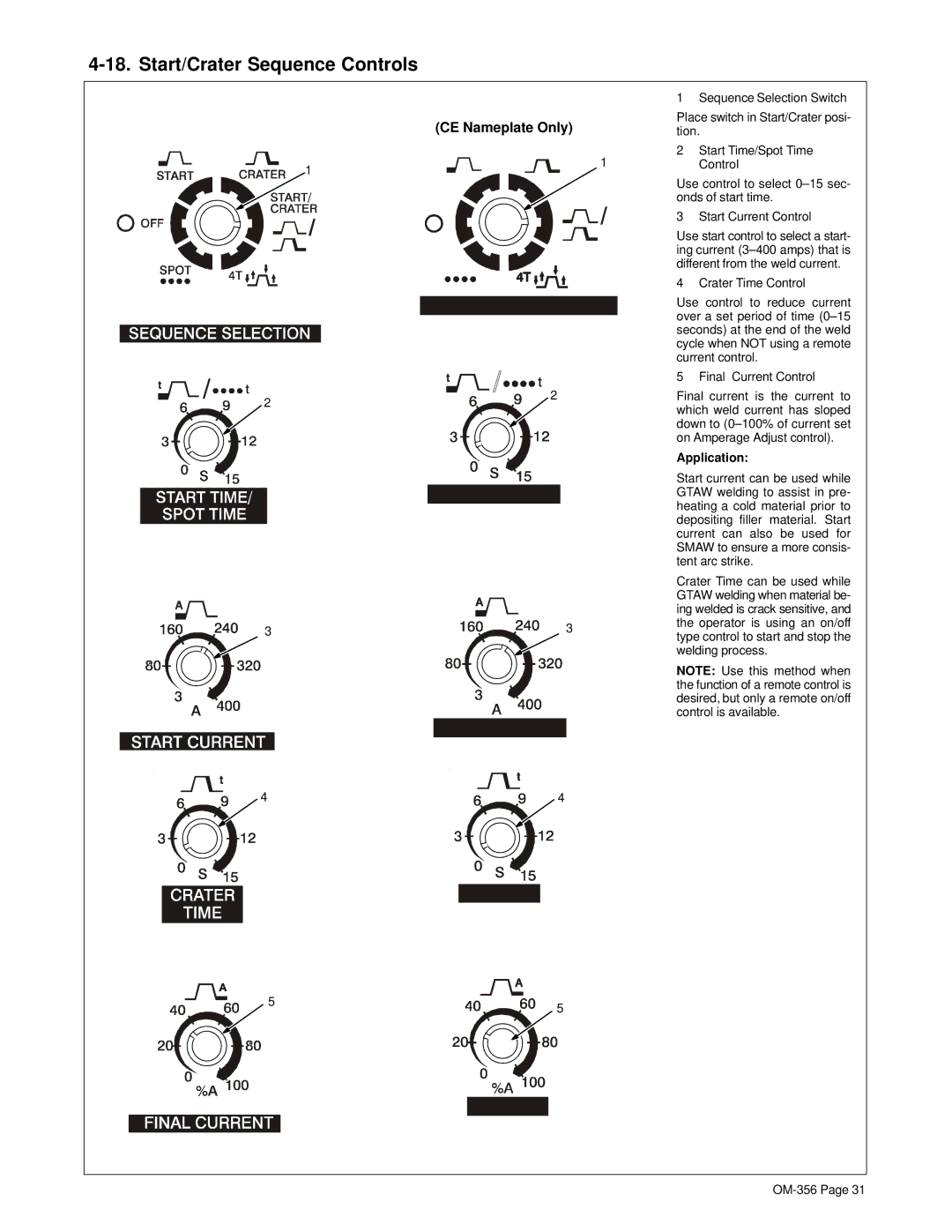

4-18. Start/Crater Sequence Controls

1

2

3

4

5

| 1 | Sequence Selection Switch | |

(CE Nameplate Only) | Place switch in Start/Crater posi- | ||

tion. | |||

| 2 | Start Time/Spot Time | |

| 1 | Control | |

| Use control to select | ||

| onds of start time. | ||

| 3 | Start Current Control | |

| Use start control to select a start- | ||

| ing current | ||

| different from the weld current. | ||

| 4 | Crater Time Control | |

| Use control to reduce current | ||

| over a set period of time | ||

| seconds) at the end of the weld | ||

| cycle when NOT using a remote | ||

| current control. | ||

| 5 | Final Current Control | |

2 | Final current is the current to | ||

| which weld current has sloped | ||

| down to | ||

| on Amperage Adjust control). | ||

| Application: | ||

| Start current can be used while | ||

| GTAW welding to assist in pre- | ||

| heating a cold material prior to | ||

| depositing filler material. Start | ||

| current can also be used for | ||

| SMAW to ensure a more consis- | ||

| tent arc strike. | ||

| Crater Time can be used while | ||

| GTAW welding when material be- | ||

| ing welded is crack sensitive, and | ||

3 | the operator is using an on/off | ||

type control to start and stop the | |||

| |||

| welding process. | ||

| NOTE: Use this method when | ||

| the function of a remote control is | ||

| desired, but only a remote on/off | ||

| control is available. | ||

4

5