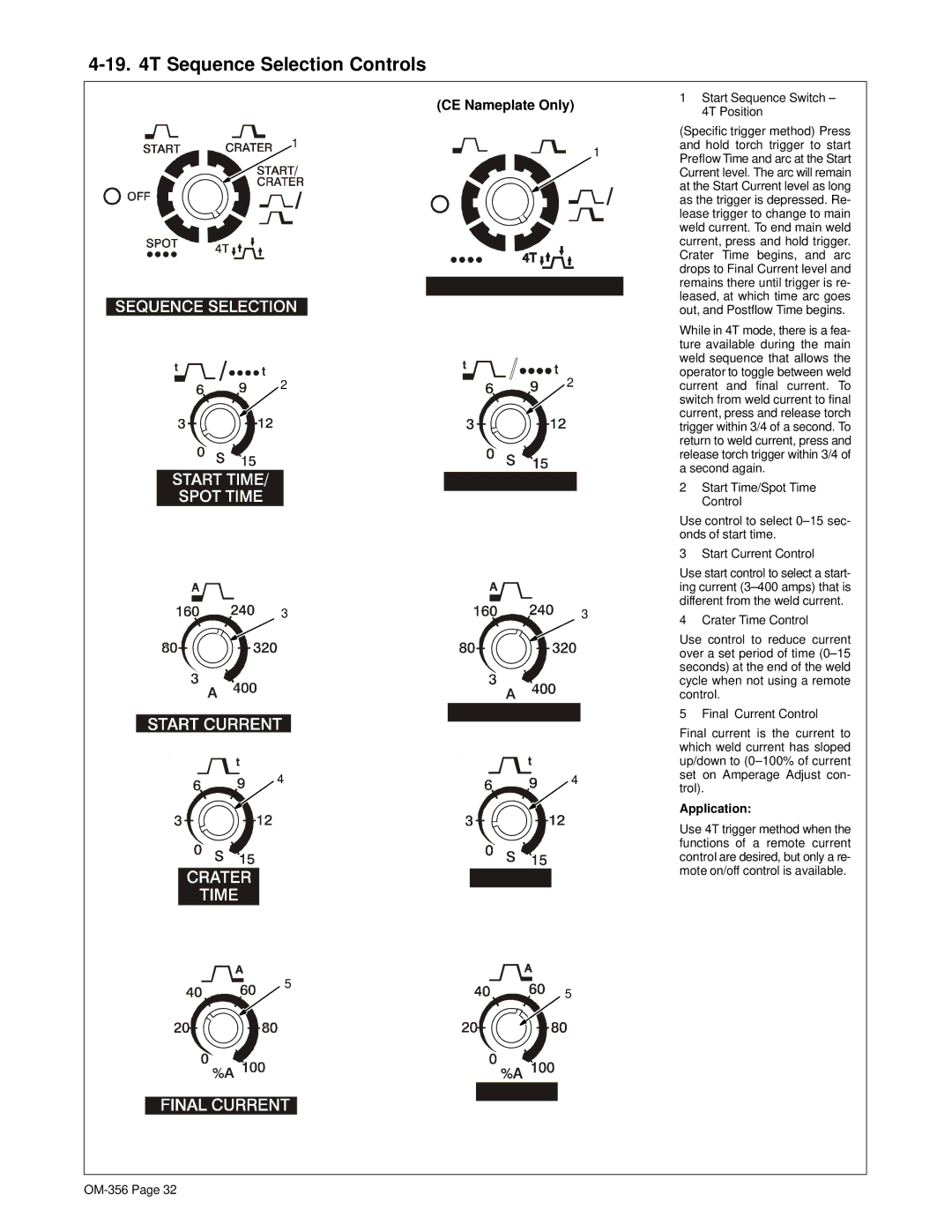

4-19. 4T Sequence Selection Controls

1

2

3

4

5

(CE Nameplate Only)

1

2

3

4

5

1Start Sequence Switch – 4T Position

(Specific trigger method) Press and hold torch trigger to start Preflow Time and arc at the Start Current level. The arc will remain at the Start Current level as long as the trigger is depressed. Re- lease trigger to change to main weld current. To end main weld current, press and hold trigger. Crater Time begins, and arc drops to Final Current level and remains there until trigger is re- leased, at which time arc goes out, and Postflow Time begins.

While in 4T mode, there is a fea- ture available during the main weld sequence that allows the operator to toggle between weld current and final current. To switch from weld current to final current, press and release torch trigger within 3/4 of a second. To return to weld current, press and release torch trigger within 3/4 of a second again.

2Start Time/Spot Time Control

Use control to select

3 Start Current Control

Use start control to select a start- ing current

4 Crater Time Control

Use control to reduce current over a set period of time

5 Final Current Control

Final current is the current to which weld current has sloped up/down to

Application:

Use 4T trigger method when the functions of a remote current control are desired, but only a re- mote on/off control is available.