SECTION 5 – OPERATION

5-1. Controls

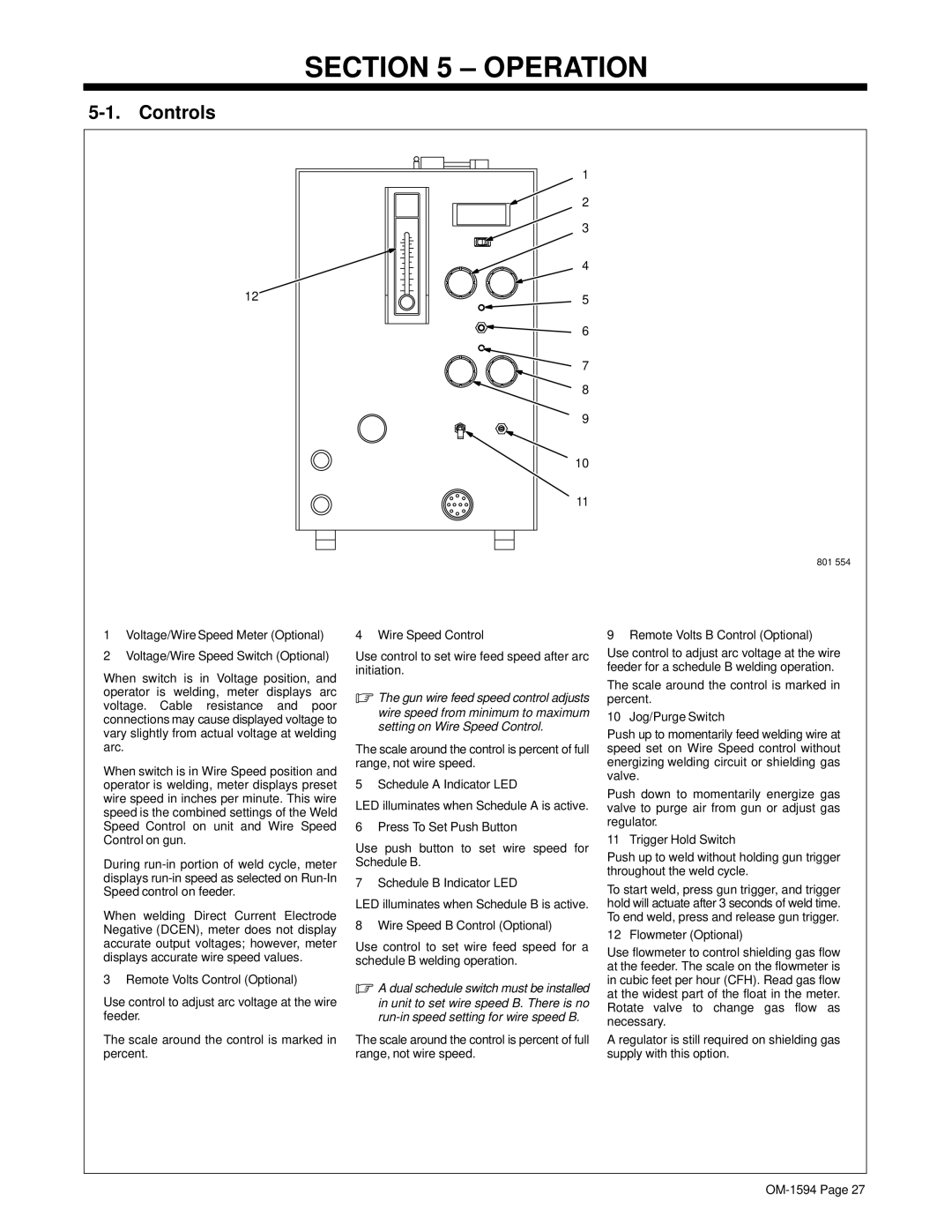

1

2

3

4

12 | 5 |

6

7

8

9

10

11

801 554

1Voltage/Wire Speed Meter (Optional)

2Voltage/Wire Speed Switch (Optional)

When switch is in Voltage position, and operator is welding, meter displays arc voltage. Cable resistance and poor connections may cause displayed voltage to vary slightly from actual voltage at welding arc.

When switch is in Wire Speed position and operator is welding, meter displays preset wire speed in inches per minute. This wire speed is the combined settings of the Weld Speed Control on unit and Wire Speed Control on gun.

During

When welding Direct Current Electrode Negative (DCEN), meter does not display accurate output voltages; however, meter displays accurate wire speed values.

3 Remote Volts Control (Optional)

Use control to adjust arc voltage at the wire feeder.

The scale around the control is marked in percent.

4 Wire Speed Control

Use control to set wire feed speed after arc initiation.

.The gun wire feed speed control adjusts wire speed from minimum to maximum setting on Wire Speed Control.

The scale around the control is percent of full range, not wire speed.

5 Schedule A Indicator LED

LED illuminates when Schedule A is active.

6 Press To Set Push Button

Use push button to set wire speed for Schedule B.

7 Schedule B Indicator LED

LED illuminates when Schedule B is active.

8 Wire Speed B Control (Optional)

Use control to set wire feed speed for a schedule B welding operation.

.A dual schedule switch must be installed in unit to set wire speed B. There is no

The scale around the control is percent of full range, not wire speed.

9 Remote Volts B Control (Optional)

Use control to adjust arc voltage at the wire feeder for a schedule B welding operation.

The scale around the control is marked in percent.

10 Jog/Purge Switch

Push up to momentarily feed welding wire at speed set on Wire Speed control without energizing welding circuit or shielding gas valve.

Push down to momentarily energize gas valve to purge air from gun or adjust gas regulator.

11 Trigger Hold Switch

Push up to weld without holding gun trigger throughout the weld cycle.

To start weld, press gun trigger, and trigger hold will actuate after 3 seconds of weld time. To end weld, press and release gun trigger.

12 Flowmeter (Optional)

Use flowmeter to control shielding gas flow at the feeder. The scale on the flowmeter is in cubic feet per hour (CFH). Read gas flow at the widest part of the float in the meter. Rotate valve to change gas flow as necessary.

A regulator is still required on shielding gas supply with this option.