.A complete Parts List is available at www.HobartWelders.com

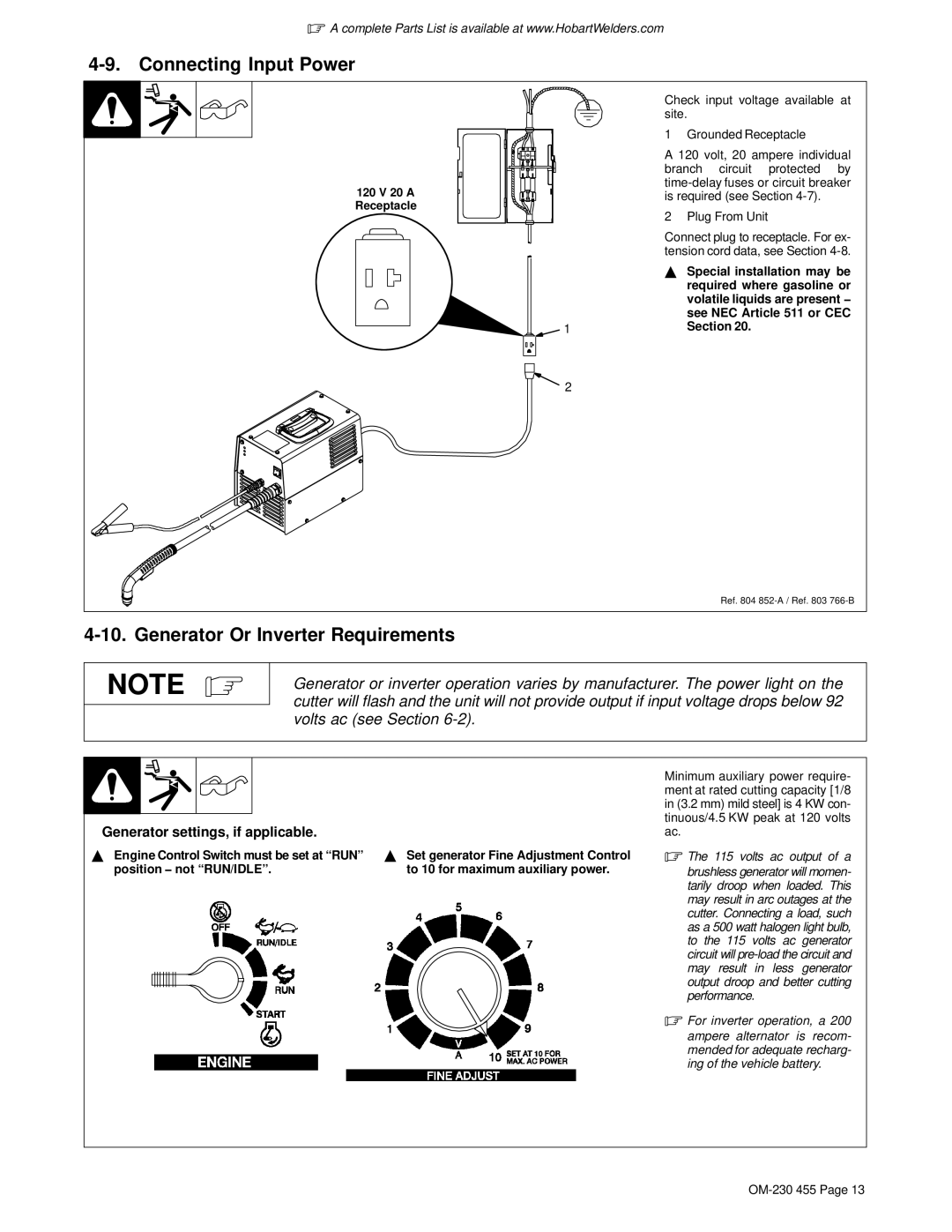

4-9. Connecting Input Power

120 V 20 A Receptacle

![]() 1

1

2

Check input voltage available at site.

1 Grounded Receptacle

A 120 volt, 20 ampere individual branch circuit protected by

2 Plug From Unit

Connect plug to receptacle. For ex- tension cord data, see Section

YSpecial installation may be required where gasoline or volatile liquids are present − see NEC Article 511 or CEC Section 20.

Ref. 804

4-10. Generator Or Inverter Requirements

NOTE

Generator or inverter operation varies by manufacturer. The power light on the cutter will flash and the unit will not provide output if input voltage drops below 92 volts ac (see Section

Generator settings, if applicable.

YEngine Control Switch must be set at “RUN” position − not “RUN/IDLE”.

YSet generator Fine Adjustment Control to 10 for maximum auxiliary power.

Minimum auxiliary power require- ment at rated cutting capacity [1/8 in (3.2 mm) mild steel] is 4 KW con- tinuous/4.5 KW peak at 120 volts ac.

.The 115 volts ac output of a brushless generator will momen- tarily droop when loaded. This may result in arc outages at the cutter. Connecting a load, such as a 500 watt halogen light bulb, to the 115 volts ac generator circuit will

.For inverter operation, a 200 ampere alternator is recom- mended for adequate recharg- ing of the vehicle battery.