.A complete Parts List is available at www.HobartWelders.com

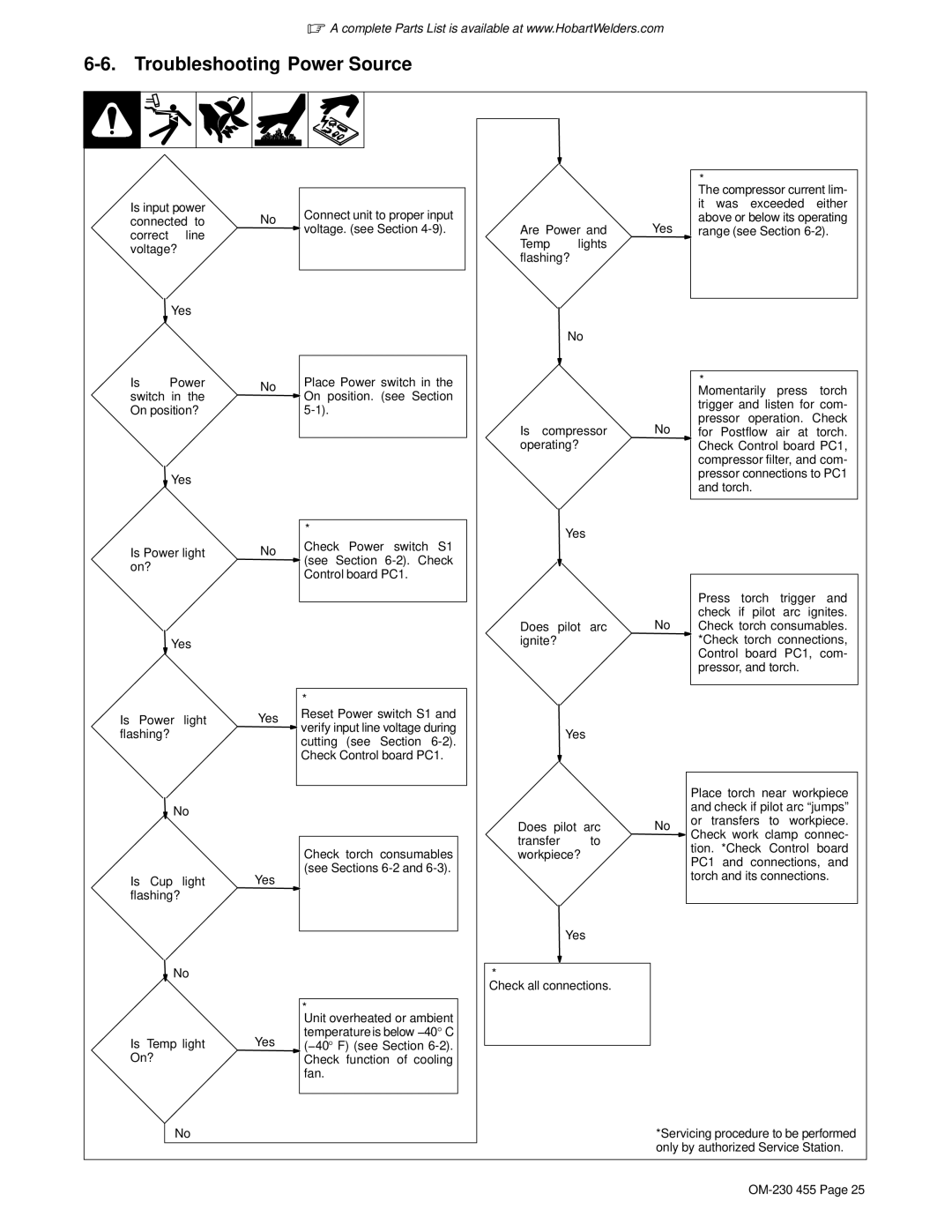

6-6. Troubleshooting Power Source

Is input power connected to correct line voltage?

![]() Yes

Yes

Is Power switch in the On position?

![]() Yes

Yes

Is Power light on?

![]() Yes

Yes

No

No

No

Connect unit to proper input ![]() voltage. (see Section

voltage. (see Section

Place Power switch in the ![]() On position. (see Section

On position. (see Section

*

Check Power switch S1 ![]() (see Section

(see Section

Control board PC1.

Are Power and

Temp lights flashing?

No

Is compressor operating?

Yes

Does pilot arc ignite?

Yes

No

No

*

The compressor current lim- it was exceeded either above or below its operating

![]() range (see Section

range (see Section

*

Momentarily press torch trigger and listen for com- pressor operation. Check for Postflow air at torch. Check Control board PC1, compressor filter, and com- pressor connections to PC1 and torch.

Press torch trigger and check if pilot arc ignites. Check torch consumables. *Check torch connections, Control board PC1, com- pressor, and torch.

Is Power light flashing?

![]() No

No

Is Cup light flashing?

![]() No

No

Is Temp light On?

Yes

Yes

Yes

*

Reset Power switch S1 and ![]() verify input line voltage during cutting (see Section

verify input line voltage during cutting (see Section

Check Control board PC1.

Check torch consumables (see Sections

*

Unit overheated or ambient temperature is below −40° C (−40° F) (see Section

Yes

Does pilot arc

transfer to workpiece?

Yes

*

Check all connections.

No

Place torch near workpiece and check if pilot arc “jumps” or transfers to workpiece.

![]() Check work clamp connec- tion. *Check Control board PC1 and connections, and torch and its connections.

Check work clamp connec- tion. *Check Control board PC1 and connections, and torch and its connections.

No | *Servicing procedure to be performed |

| only by authorized Service Station. |