Crankshaft and crankcase | 7 |

Fit plug 503 55

Connect meter 531 03

531 03 | 503 55 |

Fit plug 503 55

Connect meter 531 03

Max. permitted leakage:

20 kPa (0.2 kp/cm2) per 30 seconds.

Connect meter 531 03

Max. permitted leakage:

20 kPa (0.2 kp/cm2) per 30 seconds.

Any leakage can be difficult to localise if the crankcase is depressurised.

When leakage has been established with a vacuum, you can apply a slight overpressure

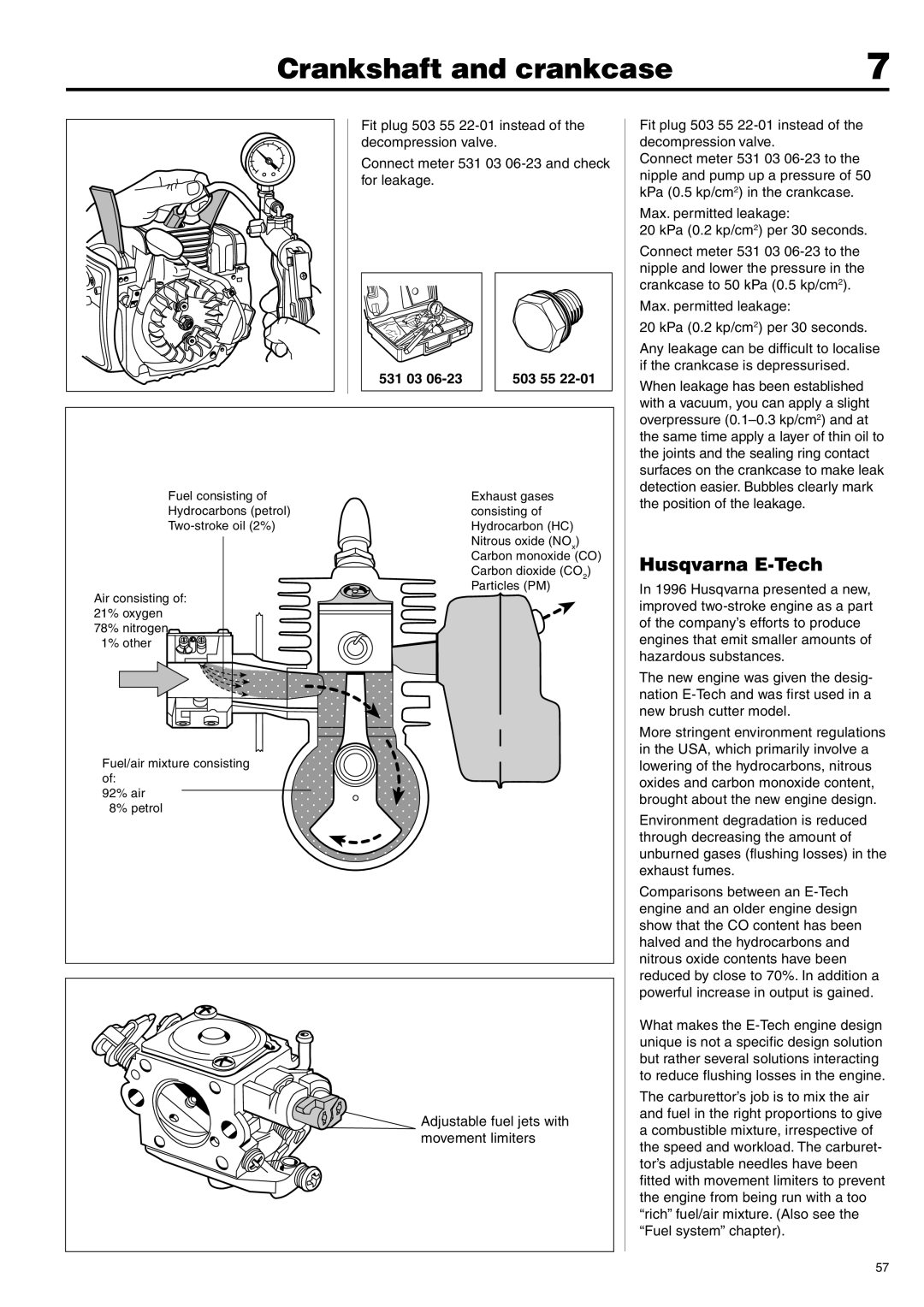

Fuel consisting of

Hydrocarbons (petrol)

Air consisting of: 21% oxygen

78% nitrogen

1% other

Fuel/air mixture consisting of:

92% air

8% petrol

Exhaust gases consisting of Hydrocarbon (HC) Nitrous oxide (NOx) Carbon monoxide (CO) Carbon dioxide (CO2) Particles (PM)

the position of the leakage.

Husqvarna E-Tech

In 1996 Husqvarna presented a new, improved

The new engine was given the desig- nation

More stringent environment regulations in the USA, which primarily involve a lowering of the hydrocarbons, nitrous oxides and carbon monoxide content, brought about the new engine design.

Environment degradation is reduced through decreasing the amount of unburned gases (flushing losses) in the exhaust fumes.

Comparisons between an

What makes the

Adjustable fuel jets with movement limiters

The carburettor’s job is to mix the air and fuel in the right proportions to give a combustible mixture, irrespective of the speed and workload. The carburet- tor’s adjustable needles have been fitted with movement limiters to prevent the engine from being run with a too “rich” fuel/air mixture. (Also see the “Fuel system” chapter).

57