This symbol indicates that the machine is in conformance with the applicable European directive.

SPECIAL INSTRUCTIONS

The disc cutter is designed to provide safe and reliable service in operating conditions corresponding with the instructions, but it can present dangers for the user and risks of damage, consequently regular on site inspection is necessary to ensure:

• Perfect technical condition (use for the purpose for which it is intended and taking into account any risks, and correction of any malfunction

| detrimental to safety). |

| • Use manufacturers’ original drums. Do not use |

| any other drum whose shape, size and |

| mounting do not fit the planer. |

| • Competent staff (qualifications, age, training) |

| who have read and understood the manual in |

| detail before starting work: any electrical, |

| mechanical or other problem should be |

| investigated by a qualified maintenance |

| engineer (electrician, maintenance manager, |

| |

English | approved dealer, etc . . .). |

• That the warnings and instructions marked on | |

the machine are followed (adequate personal | |

protection, correct use, general safety | |

| instructions, etc). |

| • That no modification, transformation or addition |

| |

| is detrimental to safety and that it is carried out |

| without prior authorization from the |

| manufacturer. |

| • Respect of the maintenance intervals and |

| periodical checks recommended. |

| • That only genuine spare parts are used for |

| repairs. |

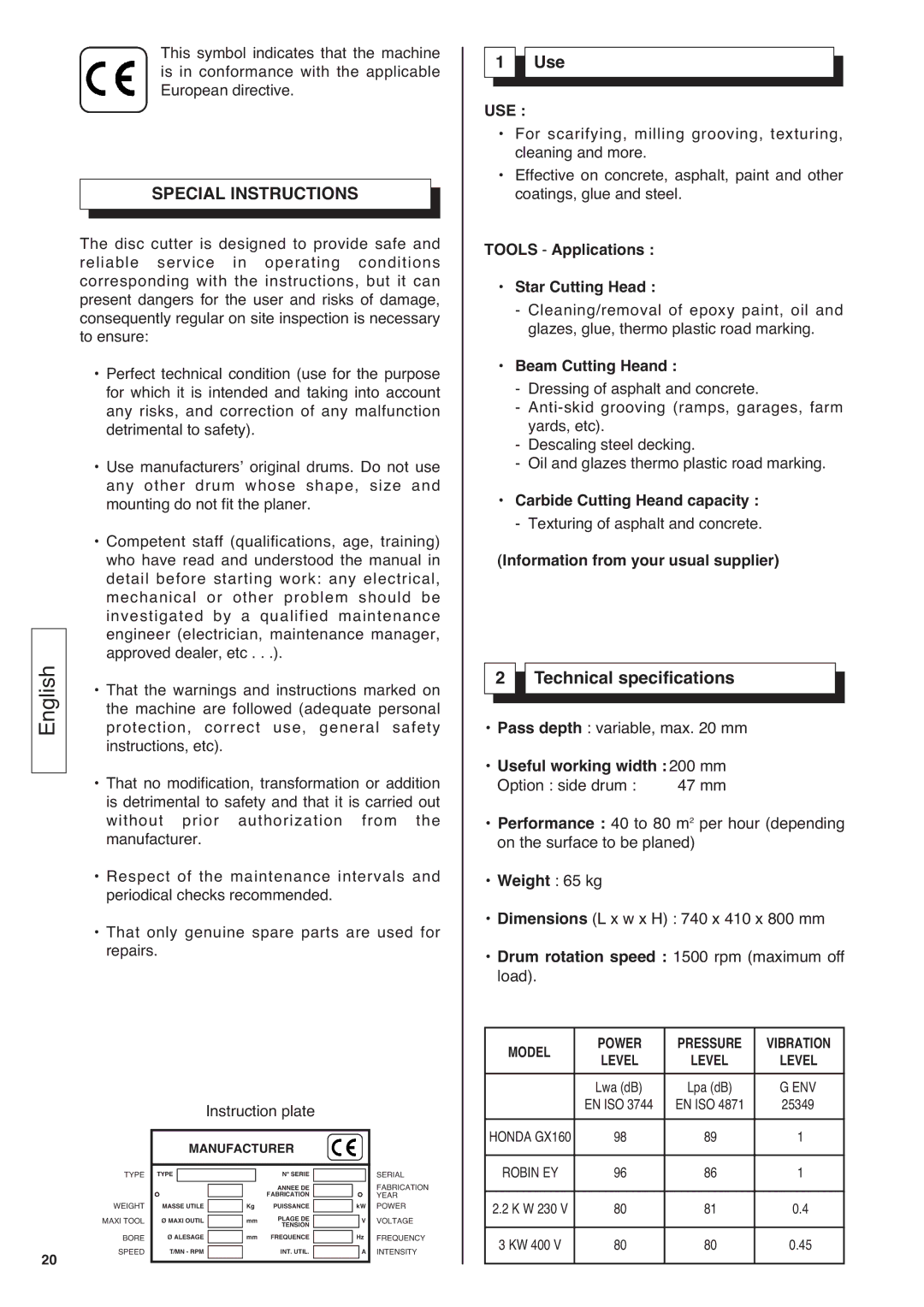

Instruction plate

|

| MANUFACTURER |

|

|

|

|

| ||||

TYPE |

|

|

|

|

|

|

|

|

|

| SERIAL |

TYPE |

|

|

|

| N° SERIE |

|

|

|

| ||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

| FABRICATION |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| ANNEE DE |

|

|

|

| |

|

|

|

|

|

| FABRICATION |

|

|

|

| YEAR |

|

|

|

|

|

|

|

|

|

| ||

WEIGHT | MASSE UTILE |

| Kg | PUISSANCE |

| kW | POWER | ||||

|

|

|

|

|

|

|

|

| |||

MAXI TOOL | Ø MAXI OUTIL |

| mm | PLAGE DE |

|

| V | VOLTAGE | |||

|

|

|

|

|

| TENSION |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

BORE | Ø ALESAGE |

| mm | FREQUENCE |

| Hz | FREQUENCY | ||||

SPEED |

|

|

|

|

|

|

|

| INTENSITY | ||

T/MN - RPM |

|

|

| INT. UTIL. |

|

| A | ||||

20

1

Use

Use

USE :

•For scarifying, milling grooving, texturing, cleaning and more.

•Effective on concrete, asphalt, paint and other coatings, glue and steel.

TOOLS - Applications :

•Star Cutting Head :

-Cleaning/removal of epoxy paint, oil and glazes, glue, thermo plastic road marking.

•Beam Cutting Heand :

-Dressing of asphalt and concrete.

-

-Descaling steel decking.

-Oil and glazes thermo plastic road marking.

•Carbide Cutting Heand capacity :

-Texturing of asphalt and concrete.

(Information from your usual supplier)

2

Technical specifications

Technical specifications

•Pass depth : variable, max. 20 mm

•Useful working width :200 mm

Option : side drum : | 247 mm |

•Performance : 40 to 80 m2 per hour (depending on the surface to be planed)

•Weight : 65 kg

•Dimensions (L x w x H) : 740 x 410 x 800 mm

•Drum rotation speed : 1500 rpm (maximum off load).

MODEL | POWER | PRESSURE | VIBRATION | |

LEVEL | LEVEL | LEVEL | ||

| ||||

|

|

|

| |

| Lwa (dB) | Lpa (dB) | G ENV | |

| EN ISO 3744 | EN ISO 4871 | 25349 | |

|

|

|

| |

HONDA GX160 | 98 | 89 | 1 | |

|

|

|

| |

ROBIN EY | 96 | 86 | 1 | |

|

|

|

| |

2.2 K W 230 V | 80 | 81 | 0.4 | |

|

|

|

| |

3 KW 400 V | 80 | 80 | 0.45 | |

|

|

|

|