Maintenance

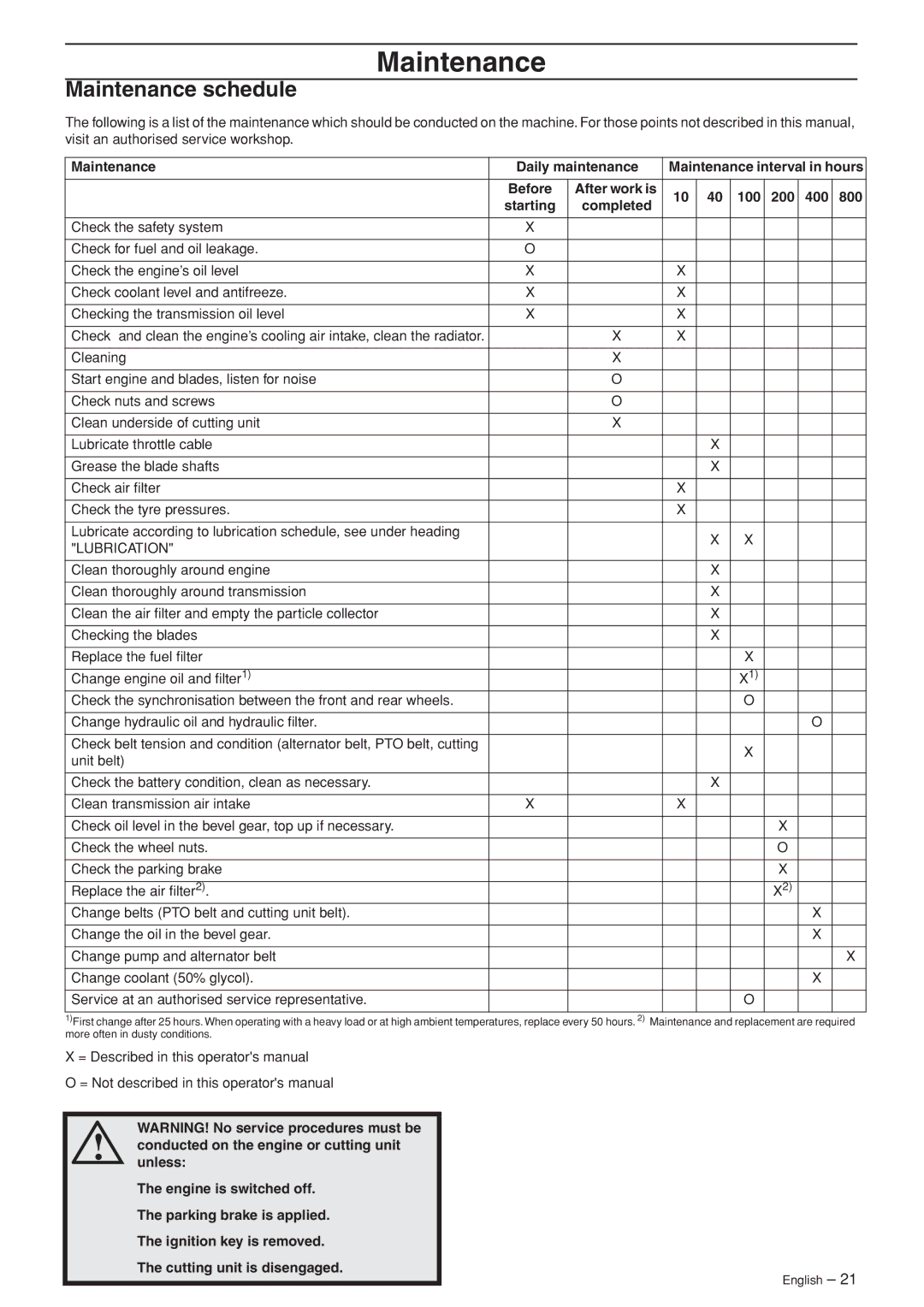

Maintenance schedule

The following is a list of the maintenance which should be conducted on the machine. For those points not described in this manual, visit an authorised service workshop.

Maintenance | Daily maintenance | Maintenance interval in hours | ||||||

|

|

|

|

|

|

|

|

|

| Before | After work is | 10 | 40 | 100 | 200 | 400 | 800 |

| starting | completed | ||||||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

Check the safety system | X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check for fuel and oil leakage. | O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the engine’s oil level | X |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check coolant level and antifreeze. | X |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Checking the transmission oil level | X |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check and clean the engine’s cooling air intake, clean the radiator. |

| X | X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cleaning |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start engine and blades, listen for noise |

| O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check nuts and screws |

| O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean underside of cutting unit |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricate throttle cable |

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Grease the blade shafts |

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Check air filter |

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check the tyre pressures. |

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lubricate according to lubrication schedule, see under heading |

|

|

| X | X |

|

|

|

"LUBRICATION" |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

Clean thoroughly around engine |

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean thoroughly around transmission |

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean the air filter and empty the particle collector |

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Checking the blades |

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Replace the fuel filter |

|

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

Change engine oil and filter1) |

|

|

|

| X1) |

|

|

|

Check the synchronisation between the front and rear wheels. |

|

|

|

| O |

|

|

|

|

|

|

|

|

|

|

|

|

Change hydraulic oil and hydraulic filter. |

|

|

|

|

|

| O |

|

|

|

|

|

|

|

|

|

|

Check belt tension and condition (alternator belt, PTO belt, cutting |

|

|

|

| X |

|

|

|

unit belt) |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

Check the battery condition, clean as necessary. |

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean transmission air intake | X |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check oil level in the bevel gear, top up if necessary. |

|

|

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

Check the wheel nuts. |

|

|

|

|

| O |

|

|

|

|

|

|

|

|

|

|

|

Check the parking brake |

|

|

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

Replace the air filter2). |

|

|

|

|

| X2) |

|

|

Change belts (PTO belt and cutting unit belt). |

|

|

|

|

|

| X |

|

|

|

|

|

|

|

|

|

|

Change the oil in the bevel gear. |

|

|

|

|

|

| X |

|

|

|

|

|

|

|

|

|

|

Change pump and alternator belt |

|

|

|

|

|

|

| X |

|

|

|

|

|

|

|

|

|

Change coolant (50% glycol). |

|

|

|

|

|

| X |

|

|

|

|

|

|

|

|

|

|

Service at an authorised service representative. |

|

|

|

| O |

|

|

|

|

|

|

|

|

|

|

|

|

1)First change after 25 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours. 2) Maintenance and replacement are required more often in dusty conditions.

X = Described in this operator's manual

O = Not described in this operator's manual

WARNING! No service procedures must be

!conducted on the engine or cutting unit unless:

The engine is switched off. The parking brake is applied. The ignition key is removed. The cutting unit is disengaged.

English – 21