Lubrication

Accessories

Lubrication or other maintenance of optional equipment or accessories is not described in this manual. This equipment too, naturally, requires maintenance. See the manuals for the respective accessories for instructions.

Pivot wheel bearings

4 nipples (sprocket and pivot shaft bearing), lubricate with grease gun until grease appears.

The cutting unit bevel gear

A sight glass is located in the plug on the front of the bevel gear.

•Check the level when the cutting unit is in the down position.

•When filling, raise the cutting unit to the transport position and remove the plug with the sight glass. Fill with gear oil SAE 80W/90.

Changing the oil

•Empty the bevel gear through the sight glass using a pump fitted with a plastic tube that extends to the bottom of the housing.

•Alternative: Remove the cutting unit and plastic covers. Place the cutting unit on its edge and empty the bevel gear through the plug.

•Fill the bevel gear with 0.4 litres of gear oil SAE 80W/90

Universal drive shaft joints

•Remove the service hatch.

•Loosen the two quick connectors on the universal drive shaft and remove the universal drive shaft.

•The universal drive shaft has two grease nipples, one on the front hub and one on the rear hub. Lubricate with a grease gun until the grease is forced out.

•Lubricate the telescopic joint of the universal drive shaft with grease.

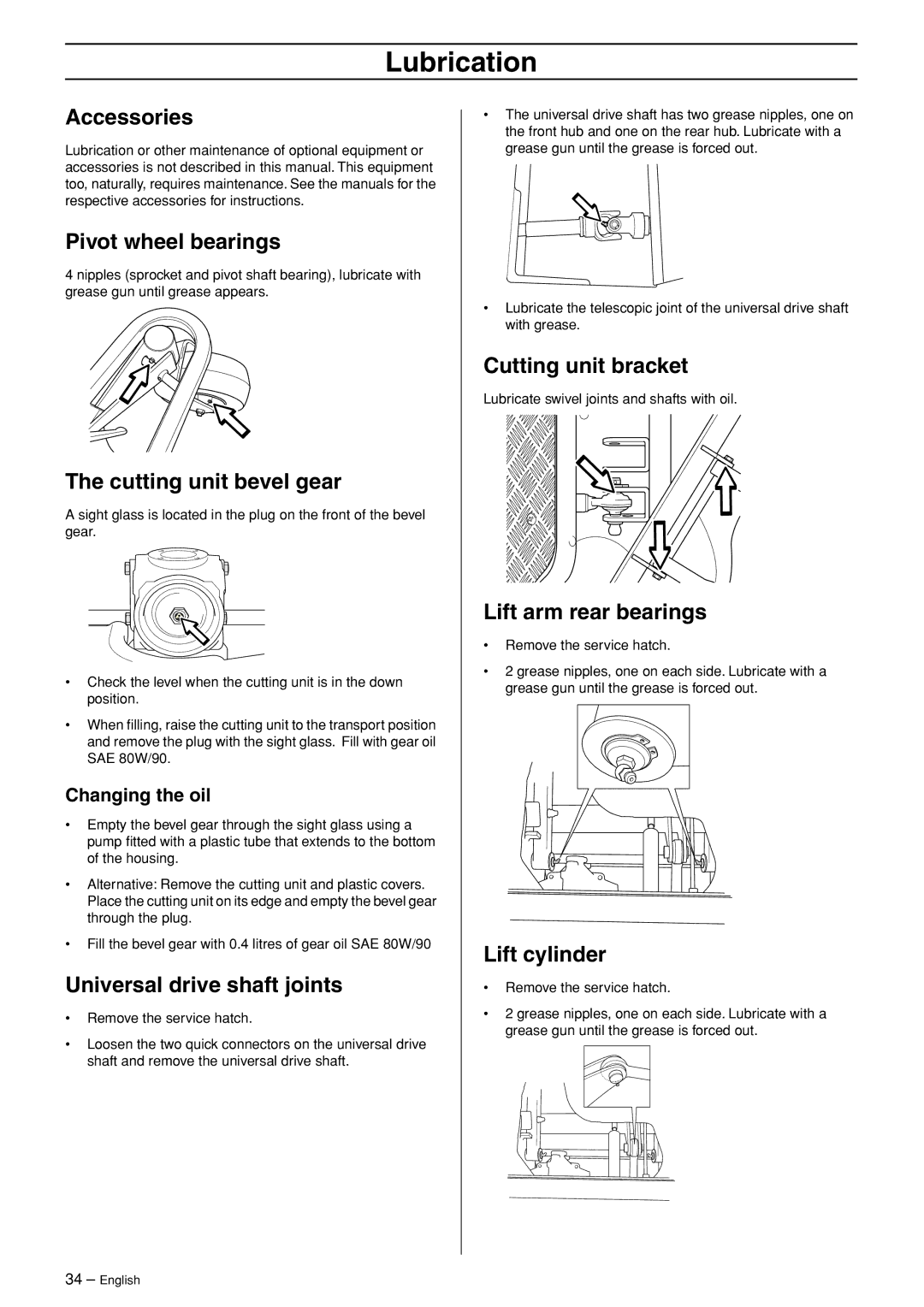

Cutting unit bracket

Lubricate swivel joints and shafts with oil.

Lift arm rear bearings

•Remove the service hatch.

•2 grease nipples, one on each side. Lubricate with a grease gun until the grease is forced out.

Lift cylinder

•Remove the service hatch.

•2 grease nipples, one on each side. Lubricate with a grease gun until the grease is forced out.

34 – English