Maintenance

Adjustment of PTO belts

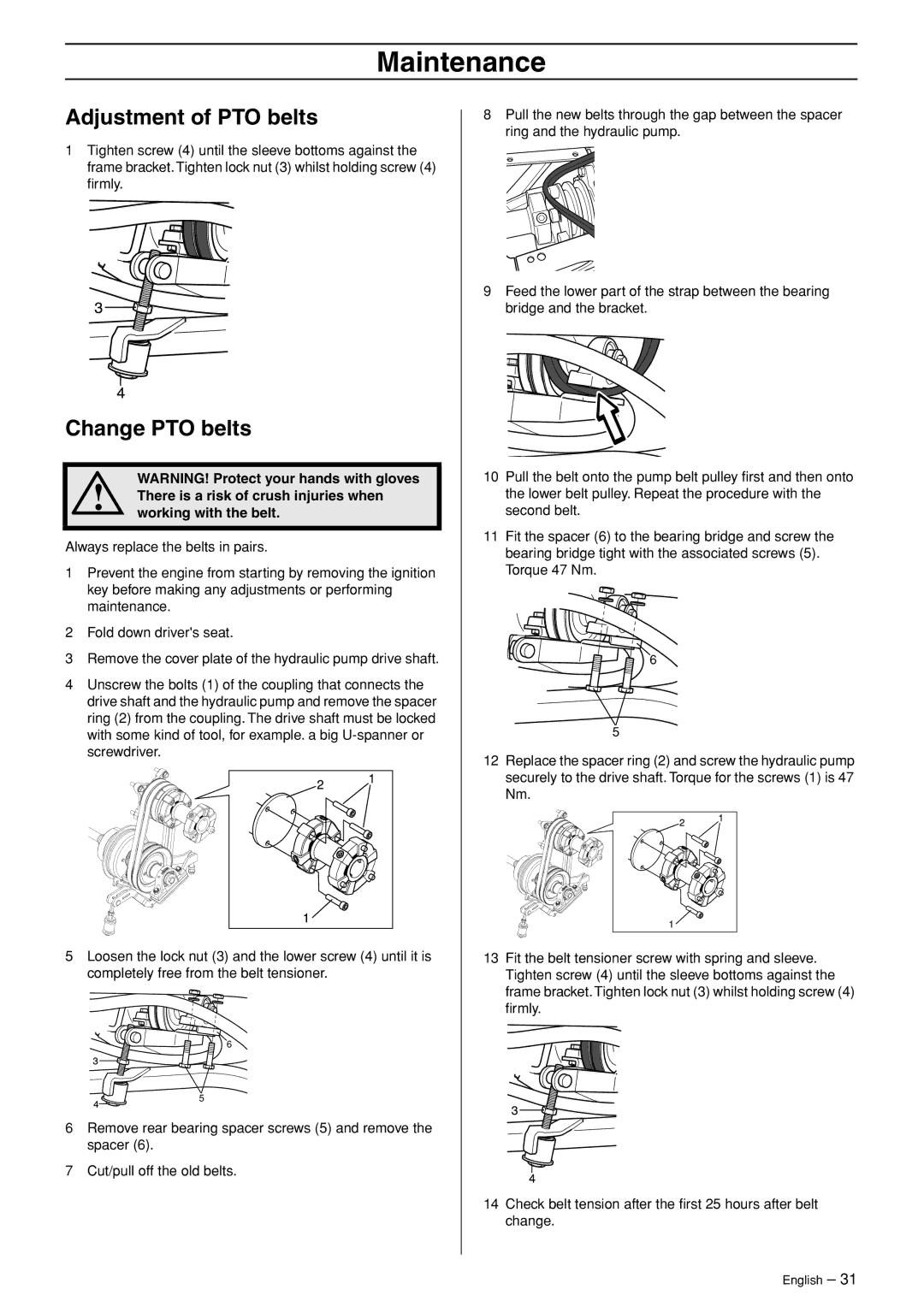

1Tighten screw (4) until the sleeve bottoms against the frame bracket.Tighten lock nut (3) whilst holding screw (4) firmly.

Change PTO belts

WARNING! Protect your hands with gloves

!There is a risk of crush injuries when working with the belt.

Always replace the belts in pairs.

1Prevent the engine from starting by removing the ignition key before making any adjustments or performing maintenance.

2Fold down driver's seat.

3Remove the cover plate of the hydraulic pump drive shaft.

4Unscrew the bolts (1) of the coupling that connects the drive shaft and the hydraulic pump and remove the spacer ring (2) from the coupling. The drive shaft must be locked with some kind of tool, for example. a big

5Loosen the lock nut (3) and the lower screw (4) until it is completely free from the belt tensioner.

6

5

6Remove rear bearing spacer screws (5) and remove the spacer (6).

7Cut/pull off the old belts.

8Pull the new belts through the gap between the spacer ring and the hydraulic pump.

9Feed the lower part of the strap between the bearing bridge and the bracket.

10Pull the belt onto the pump belt pulley first and then onto the lower belt pulley. Repeat the procedure with the second belt.

11Fit the spacer (6) to the bearing bridge and screw the bearing bridge tight with the associated screws (5). Torque 47 Nm.

6

5

12Replace the spacer ring (2) and screw the hydraulic pump securely to the drive shaft. Torque for the screws (1) is 47 Nm.

13Fit the belt tensioner screw with spring and sleeve. Tighten screw (4) until the sleeve bottoms against the frame bracket.Tighten lock nut (3) whilst holding screw (4) firmly.

14Check belt tension after the first 25 hours after belt change.

English – 31