Tailstock

If the handle will not lock the tailstock, follow the procedure below :

1.Lower the handle to the unlocked position.

2.Slide the tailstock to an area that allows access to the underside of the tailstock.

3.Tighten tailstock clamping bolt (underside of tailstock) 1/4 turn. Test for proper locking. Repeat as necessary.

Tailstock Off-Set

Follow the procedure below to

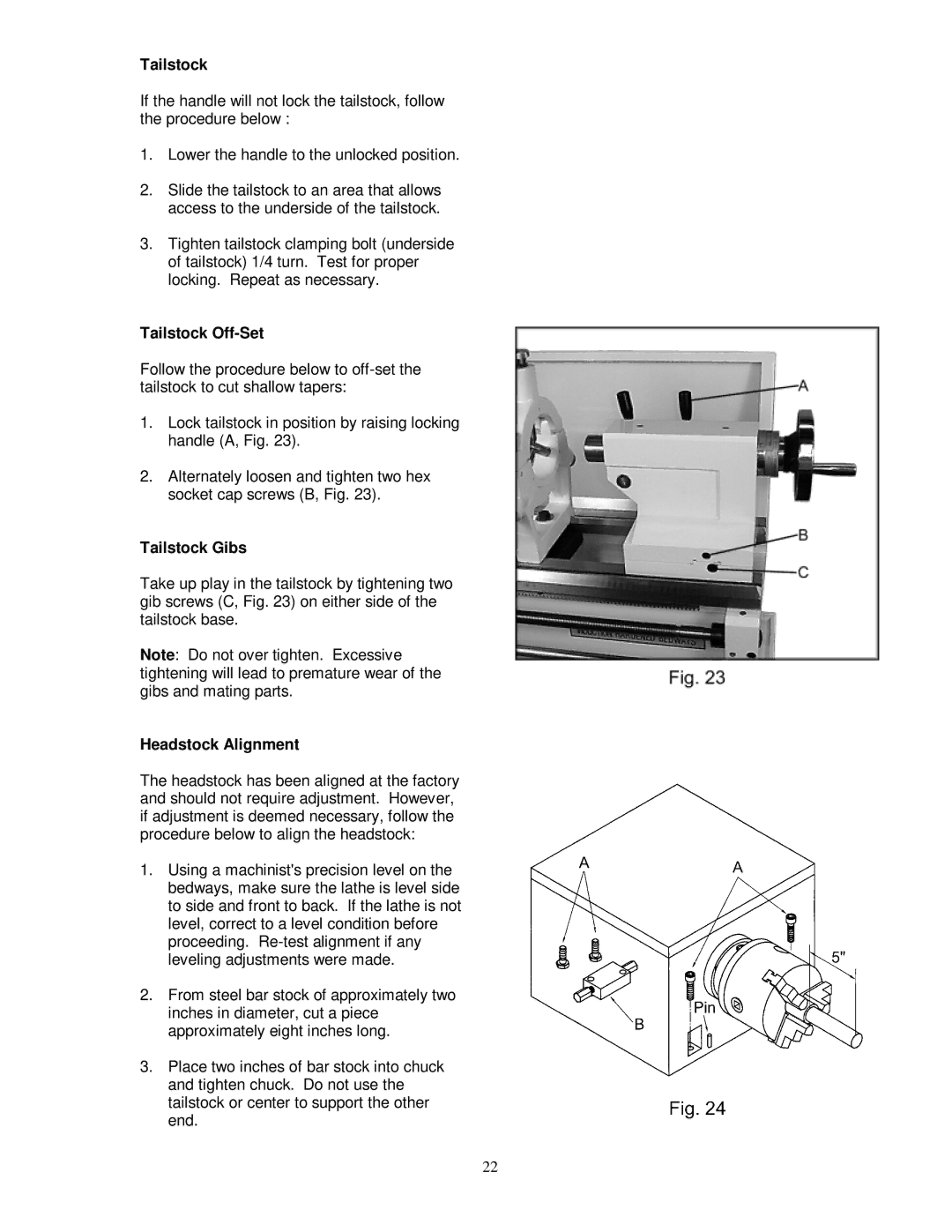

1.Lock tailstock in position by raising locking handle (A, Fig. 23).

2.Alternately loosen and tighten two hex socket cap screws (B, Fig. 23).

Tailstock Gibs

Take up play in the tailstock by tightening two gib screws (C, Fig. 23) on either side of the tailstock base.

Note: Do not over tighten. Excessive tightening will lead to premature wear of the gibs and mating parts.

Headstock Alignment

The headstock has been aligned at the factory and should not require adjustment. However, if adjustment is deemed necessary, follow the procedure below to align the headstock:

1.Using a machinist's precision level on the bedways, make sure the lathe is level side to side and front to back. If the lathe is not level, correct to a level condition before proceeding.

2.From steel bar stock of approximately two inches in diameter, cut a piece approximately eight inches long.

3.Place two inches of bar stock into chuck and tighten chuck. Do not use the tailstock or center to support the other end.

22