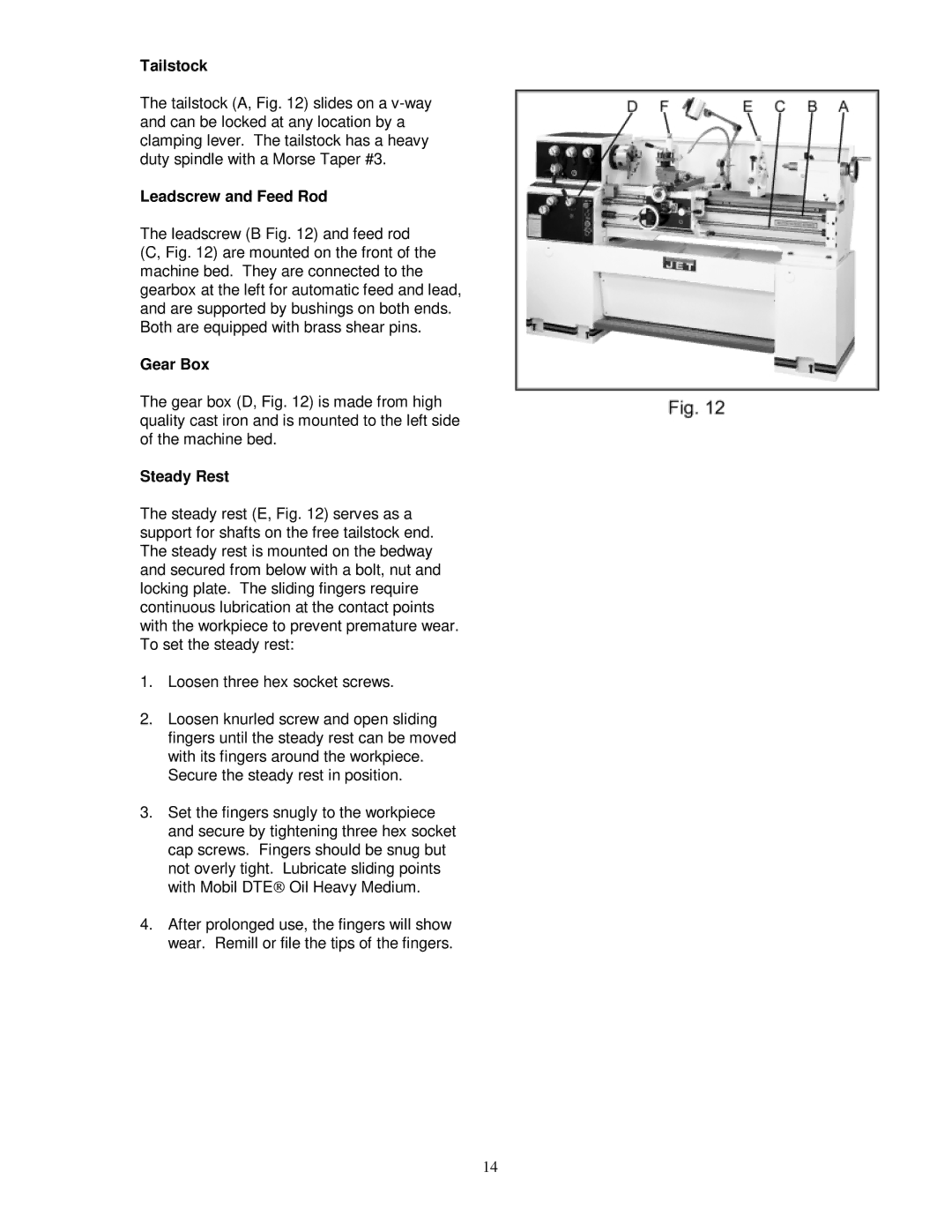

Tailstock

The tailstock (A, Fig. 12) slides on a

Leadscrew and Feed Rod

The leadscrew (B Fig. 12) and feed rod (C, Fig. 12) are mounted on the front of the machine bed. They are connected to the gearbox at the left for automatic feed and lead, and are supported by bushings on both ends. Both are equipped with brass shear pins.

Gear Box

The gear box (D, Fig. 12) is made from high quality cast iron and is mounted to the left side of the machine bed.

Steady Rest

The steady rest (E, Fig. 12) serves as a support for shafts on the free tailstock end. The steady rest is mounted on the bedway and secured from below with a bolt, nut and locking plate. The sliding fingers require continuous lubrication at the contact points with the workpiece to prevent premature wear. To set the steady rest:

1.Loosen three hex socket screws.

2.Loosen knurled screw and open sliding fingers until the steady rest can be moved with its fingers around the workpiece. Secure the steady rest in position.

3.Set the fingers snugly to the workpiece and secure by tightening three hex socket cap screws. Fingers should be snug but

not overly tight. Lubricate sliding points with Mobil DTE Oil Heavy Medium.

4.After prolonged use, the fingers will show wear. Remill or file the tips of the fingers.

14