Automatic Feed Operation and Feed Changes

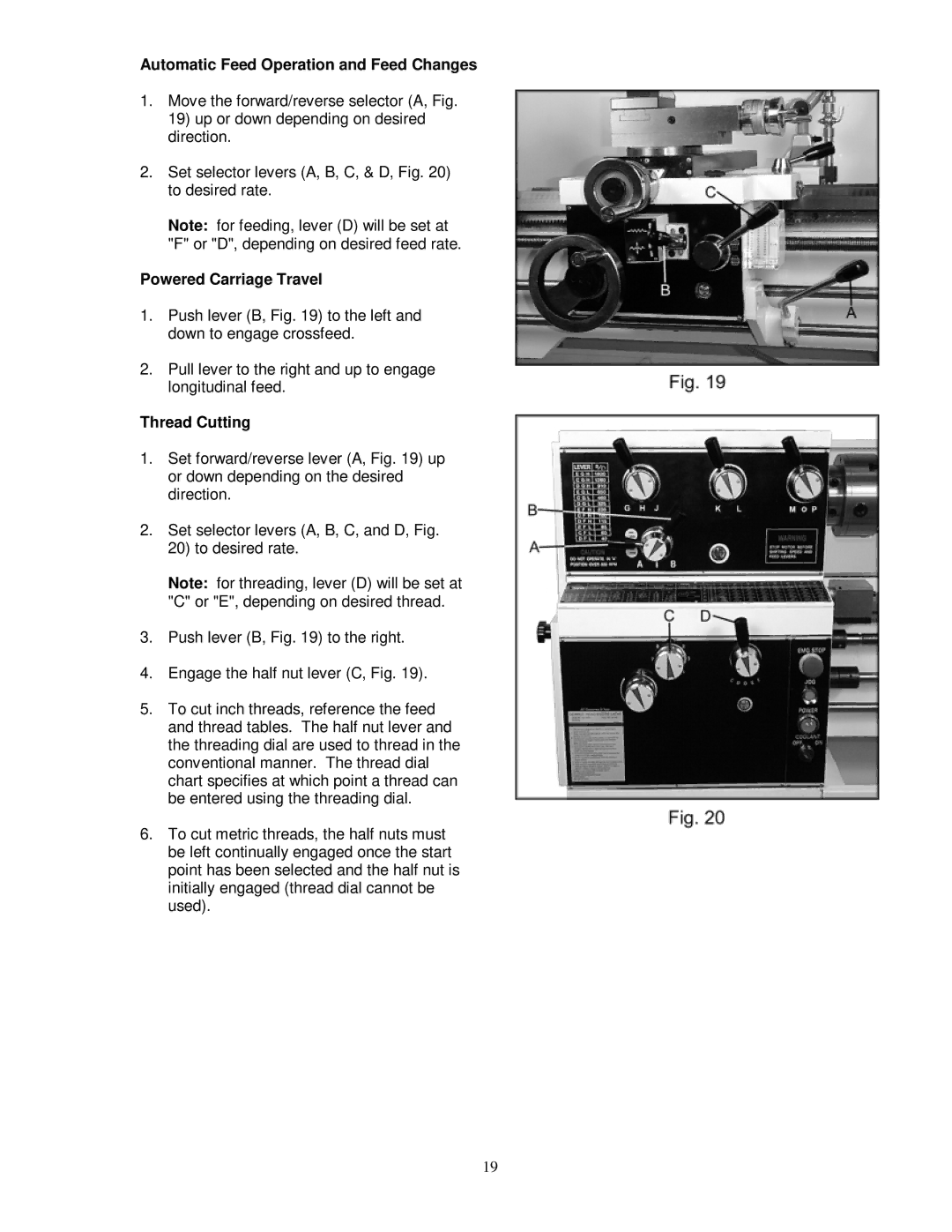

1.Move the forward/reverse selector (A, Fig. 19) up or down depending on desired direction.

2.Set selector levers (A, B, C, & D, Fig. 20) to desired rate.

Note: for feeding, lever (D) will be set at "F" or "D", depending on desired feed rate.

Powered Carriage Travel

1.Push lever (B, Fig. 19) to the left and down to engage crossfeed.

2.Pull lever to the right and up to engage longitudinal feed.

Thread Cutting

1.Set forward/reverse lever (A, Fig. 19) up or down depending on the desired direction.

2.Set selector levers (A, B, C, and D, Fig. 20) to desired rate.

Note: for threading, lever (D) will be set at "C" or "E", depending on desired thread.

3.Push lever (B, Fig. 19) to the right.

4.Engage the half nut lever (C, Fig. 19).

5.To cut inch threads, reference the feed and thread tables. The half nut lever and the threading dial are used to thread in the conventional manner. The thread dial chart specifies at which point a thread can be entered using the threading dial.

6.To cut metric threads, the half nuts must be left continually engaged once the start point has been selected and the half nut is initially engaged (thread dial cannot be used).

19