Belt Replacement and Adjustment

1.Disconnect machine from the power source (unplug).

2.Open the end gear cover and lower cover on the headstock side.

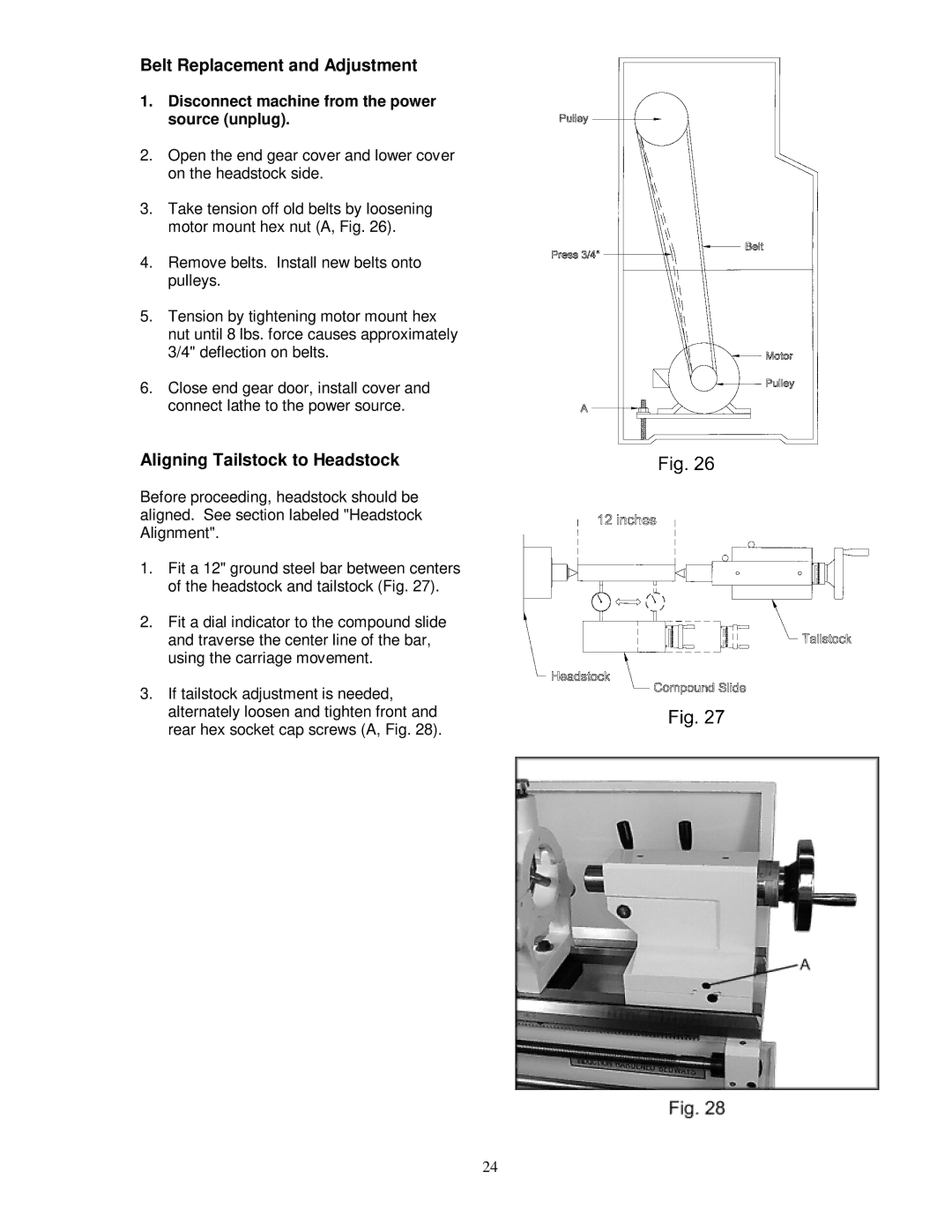

3.Take tension off old belts by loosening motor mount hex nut (A, Fig. 26).

4.Remove belts. Install new belts onto pulleys.

5.Tension by tightening motor mount hex nut until 8 lbs. force causes approximately 3/4" deflection on belts.

6.Close end gear door, install cover and connect lathe to the power source.

Aligning Tailstock to Headstock

Before proceeding, headstock should be aligned. See section labeled "Headstock Alignment".

1.Fit a 12" ground steel bar between centers of the headstock and tailstock (Fig. 27).

2.Fit a dial indicator to the compound slide and traverse the center line of the bar, using the carriage movement.

3.If tailstock adjustment is needed, alternately loosen and tighten front and rear hex socket cap screws (A, Fig. 28).

24