4.Lift up on the motor and install the belt around the pulley grooves, as shown in Figure 4. Allow the motor to drop back down, then push it down farther to tension the belt. (For further information on belt tension and belt position on the grooves, see page 15.)

5.Tighten the knob (A, Figure 3).

6.Close the pulley cover and secure it with the pan head screw and hex nut.

Figure 4

Stock Stop

The stock stop is used for making multiple cuts of the same length.

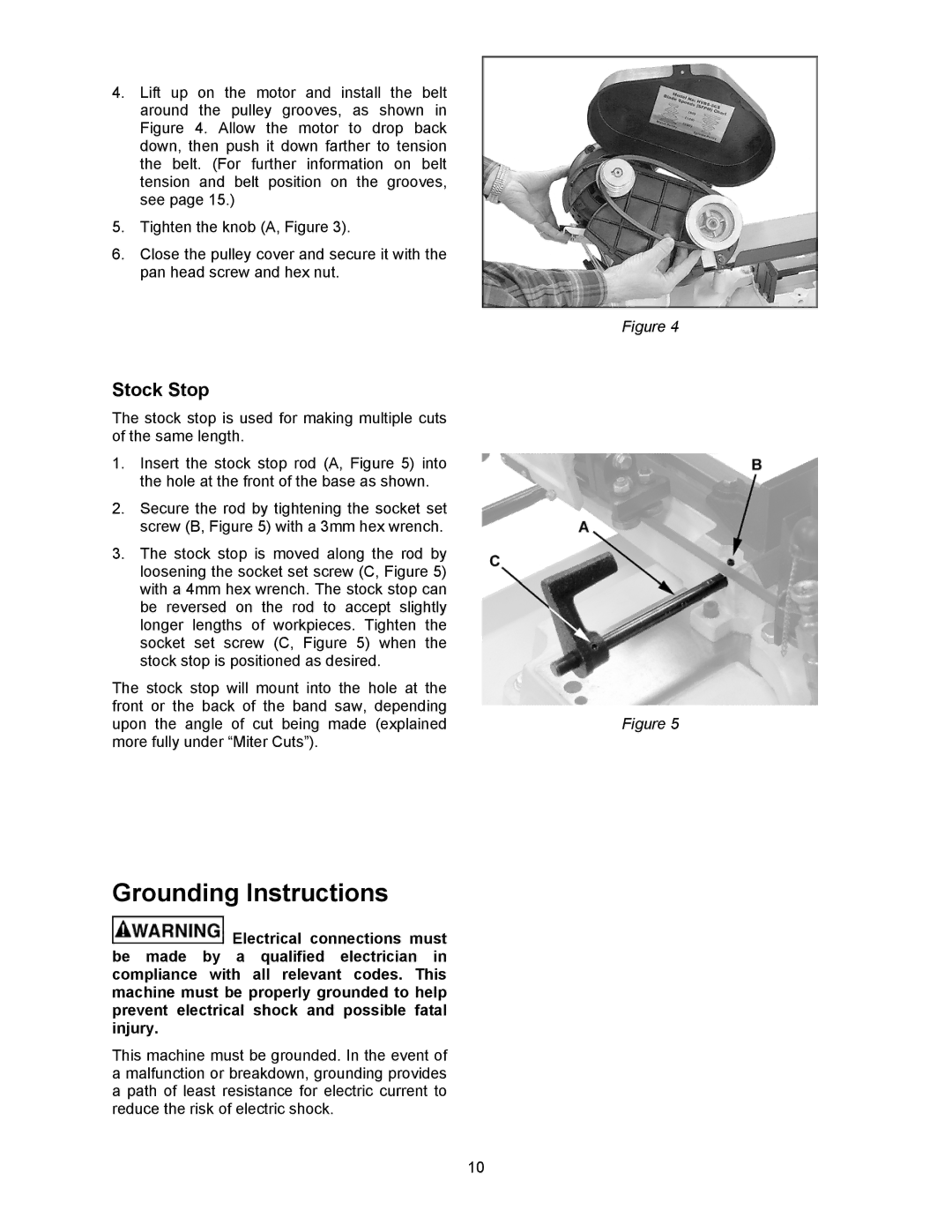

1.Insert the stock stop rod (A, Figure 5) into the hole at the front of the base as shown.

2.Secure the rod by tightening the socket set screw (B, Figure 5) with a 3mm hex wrench.

3.The stock stop is moved along the rod by loosening the socket set screw (C, Figure 5) with a 4mm hex wrench. The stock stop can be reversed on the rod to accept slightly longer lengths of workpieces. Tighten the socket set screw (C, Figure 5) when the stock stop is positioned as desired.

The stock stop will mount into the hole at the |

|

front or the back of the band saw, depending |

|

upon the angle of cut being made (explained | Figure 5 |

more fully under “Miter Cuts”). |

|

Grounding Instructions

![]() Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded to help prevent electrical shock and possible fatal injury.

Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded to help prevent electrical shock and possible fatal injury.

This machine must be grounded. In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock.

10