stops, raise the

Figure 35

Bevel Ripping

This cut is the same as ripping except the blade bevel angle is set to an angle other than “0º.

Ripping Small Pieces

To avoid injury from blade contact, never make cuts narrower than 1/2 in. wide.

1.It is unsafe to rip small pieces. Instead, rip a larger piece to obtain the size of the desired piece.

2.When a small width is to be ripped and your hand cannot safely pass between the blade and the rip fence, use one or more push sticks to move the workpiece. Always use a push stick during ripping operations.

Crosscutting

![]() Do not allow familiarity or frequent use of your table saw to cause careless mistakes. Remember that even a careless fraction of a second is enough to cause a severe injury.

Do not allow familiarity or frequent use of your table saw to cause careless mistakes. Remember that even a careless fraction of a second is enough to cause a severe injury.

![]() Keep both hands away from the blade and the path of the blade.

Keep both hands away from the blade and the path of the blade.

![]() Never attempt to pull the workpiece backwards during a cutting operation. This will cause kickback and serious injury to the user can occur.

Never attempt to pull the workpiece backwards during a cutting operation. This will cause kickback and serious injury to the user can occur.

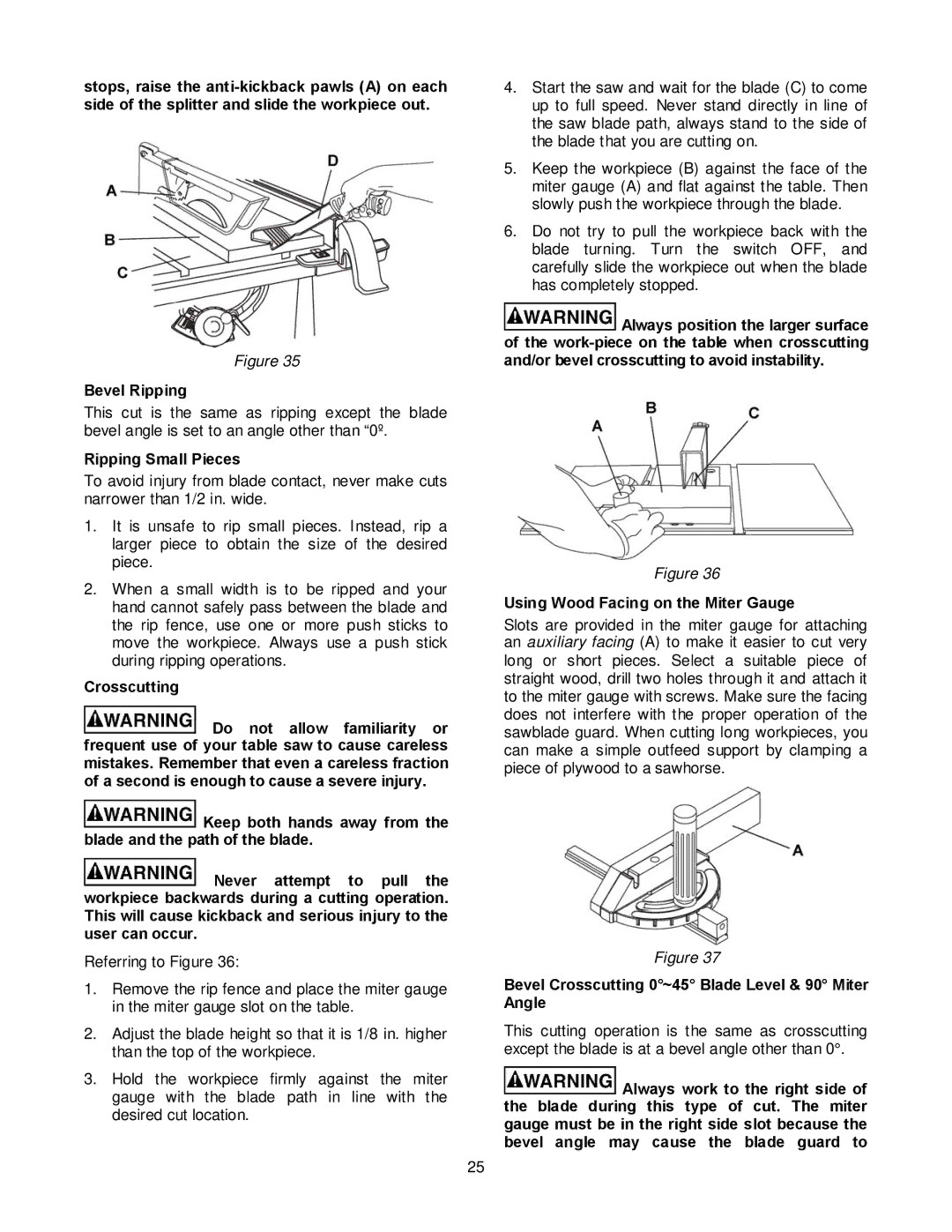

Referring to Figure 36:

1.Remove the rip fence and place the miter gauge in the miter gauge slot on the table.

2.Adjust the blade height so that it is 1/8 in. higher than the top of the workpiece.

3.Hold the workpiece firmly against the miter gauge with the blade path in line with the desired cut location.

4.Start the saw and wait for the blade (C) to come up to full speed. Never stand directly in line of the saw blade path, always stand to the side of the blade that you are cutting on.

5.Keep the workpiece (B) against the face of the miter gauge (A) and flat against the table. Then slowly push the workpiece through the blade.

6.Do not try to pull the workpiece back with the blade turning. Turn the switch OFF, and carefully slide the workpiece out when the blade has completely stopped.

![]() Always position the larger surface of the

Always position the larger surface of the

Figure 36

Using Wood Facing on the Miter Gauge

Slots are provided in the miter gauge for attaching an auxiliary facing (A) to make it easier to cut very long or short pieces. Select a suitable piece of straight wood, drill two holes through it and attach it to the miter gauge with screws. Make sure the facing does not interfere with the proper operation of the sawblade guard. When cutting long workpieces, you can make a simple outfeed support by clamping a piece of plywood to a sawhorse.

Figure 37

Bevel Crosscutting 0°~45° Blade Level & 90° Miter Angle

This cutting operation is the same as crosscutting except the blade is at a bevel angle other than 0°.

![]() Always work to the right side of the blade during this type of cut. The miter gauge must be in the right side slot because the bevel angle may cause the blade guard to

Always work to the right side of the blade during this type of cut. The miter gauge must be in the right side slot because the bevel angle may cause the blade guard to

25