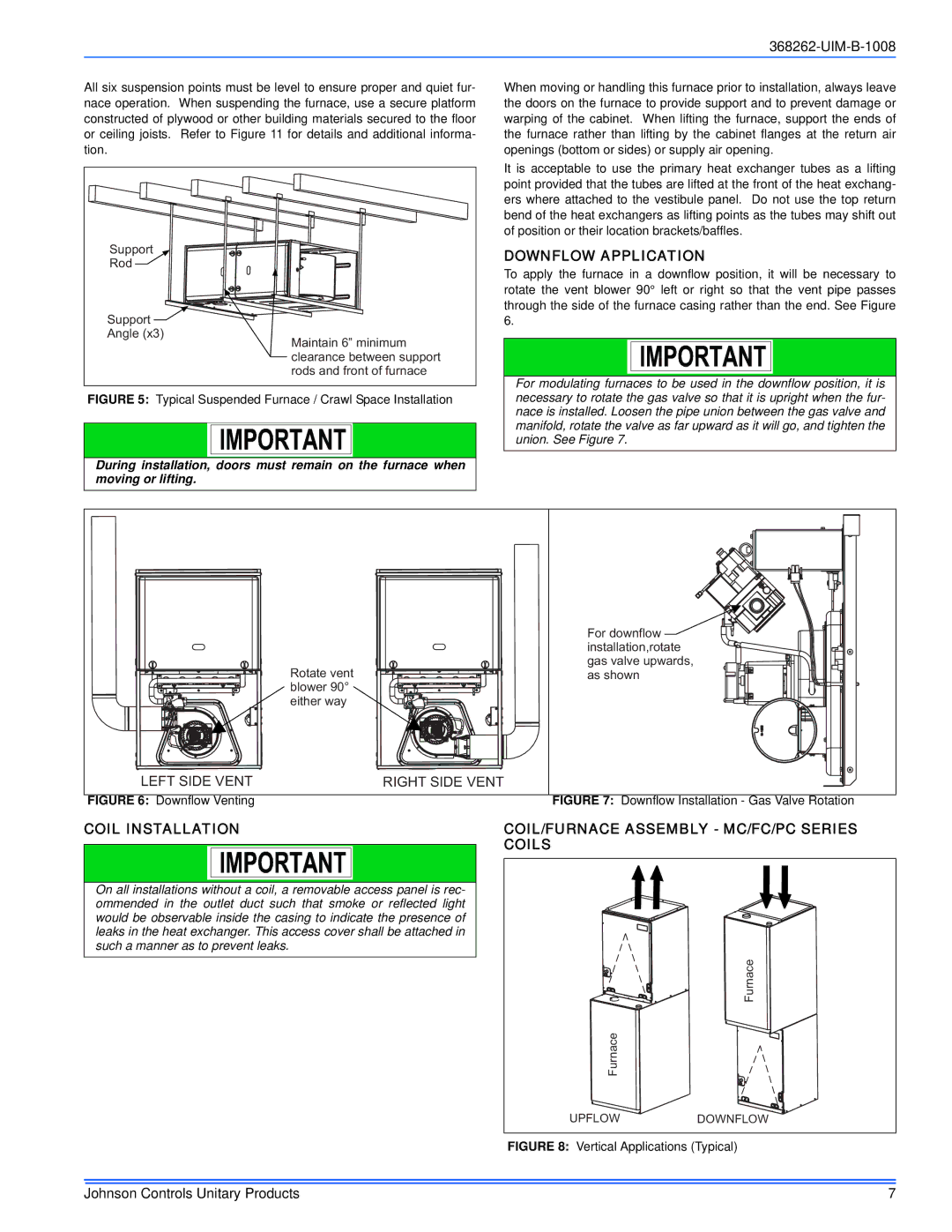

All six suspension points must be level to ensure proper and quiet fur- nace operation. When suspending the furnace, use a secure platform constructed of plywood or other building materials secured to the floor or ceiling joists. Refer to Figure 11 for details and additional informa- tion.

Support

Rod

Support

Angle (x3)

Maintain 6” minimum clearance between support rods and front of furnace

FIGURE 5: Typical Suspended Furnace / Crawl Space Installation

During installation, doors must remain on the furnace when moving or lifting.

When moving or handling this furnace prior to installation, always leave the doors on the furnace to provide support and to prevent damage or warping of the cabinet. When lifting the furnace, support the ends of the furnace rather than lifting by the cabinet flanges at the return air openings (bottom or sides) or supply air opening.

It is acceptable to use the primary heat exchanger tubes as a lifting point provided that the tubes are lifted at the front of the heat exchang- ers where attached to the vestibule panel. Do not use the top return bend of the heat exchangers as lifting points as the tubes may shift out of position or their location brackets/baffles.

DOWNFLOW APPLICATION

To apply the furnace in a downflow position, it will be necessary to rotate the vent blower 90° left or right so that the vent pipe passes through the side of the furnace casing rather than the end. See Figure 6.

For modulating furnaces to be used in the downflow position, it is necessary to rotate the gas valve so that it is upright when the fur- nace is installed. Loosen the pipe union between the gas valve and manifold, rotate the valve as far upward as it will go, and tighten the union. See Figure 7.

Rotate vent blower 90° either way

LEFT SIDE VENT | RIGHT SIDE VENT |

FIGURE 6: Downflow Venting

For downflow ![]() installation,rotate

installation,rotate

gas valve upwards, as shown

FIGURE 7: Downflow Installation - Gas Valve Rotation

COIL INSTALLATION

On all installations without a coil, a removable access panel is rec- ommended in the outlet duct such that smoke or reflected light would be observable inside the casing to indicate the presence of leaks in the heat exchanger. This access cover shall be attached in such a manner as to prevent leaks.

COIL/FURNACE ASSEMBLY - MC/FC/PC SERIES COILS

Furnace

Furnace

UPFLOWDOWNFLOW

FIGURE 8: Vertical Applications (Typical)

Johnson Controls Unitary Products | 7 |