Preparing for use

surfaces, slots for letters or butt jointed connections, notches, tongue and groove joints etc.

Cove cutter bit / cove cutter bit with bearing: Cove cutter bits are used for edge profiling (e.g. concave edges), for constructing bureaux (hinged connections with concave profiles), for making dec- orative grooves, for texturing surfaces, for cutting juice channels etc.

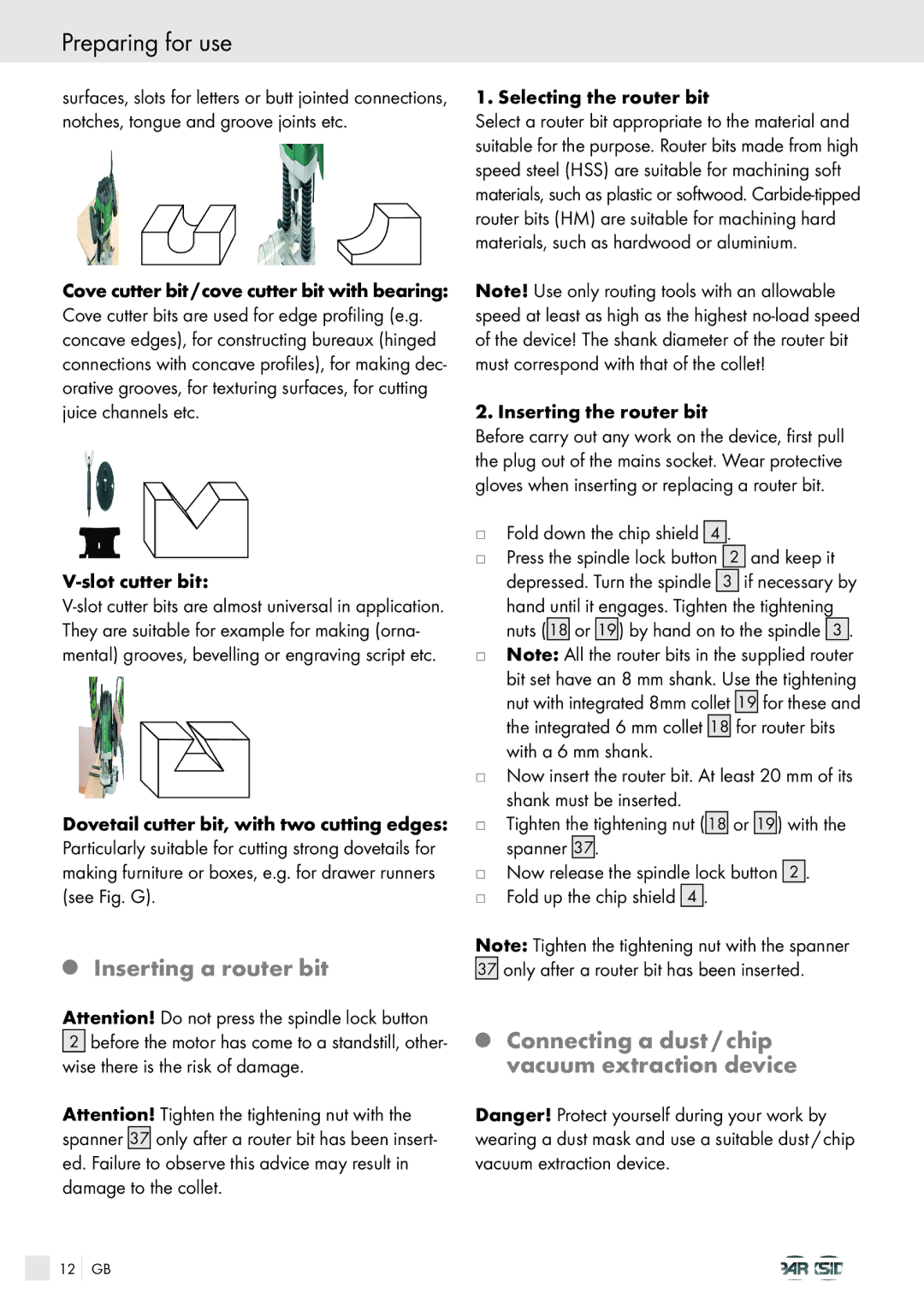

V-slot cutter bit:

Dovetail cutter bit, with two cutting edges: Particularly suitable for cutting strong dovetails for making furniture or boxes, e.g. for drawer runners (see Fig. G).

QInserting a router bit

Attention! Do not press the spindle lock button

2before the motor has come to a standstill, other- wise there is the risk of damage.

Attention! Tighten the tightening nut with the spanner 37 only after a router bit has been insert- ed. Failure to observe this advice may result in damage to the collet.

1. Selecting the router bit

Select a router bit appropriate to the material and suitable for the purpose. Router bits made from high speed steel (HSS) are suitable for machining soft materials, such as plastic or softwood.

Note! Use only routing tools with an allowable speed at least as high as the highest

2. Inserting the router bit

Before carry out any work on the device, first pull the plug out of the mains socket. Wear protective gloves when inserting or replacing a router bit.

jFold down the chip shield 4 .

jPress the spindle lock button 2 and keep it depressed. Turn the spindle 3 if necessary by hand until it engages. Tighten the tightening nuts ( 18 or 19) by hand on to the spindle 3 .

jNote: All the router bits in the supplied router bit set have an 8 mm shank. Use the tightening nut with integrated 8mm collet 19 for these and the integrated 6 mm collet 18 for router bits with a 6 mm shank.

jNow insert the router bit. At least 20 mm of its shank must be inserted.

jTighten the tightening nut ( 18 or 19) with the spanner 37.

jNow release the spindle lock button 2 .

jFold up the chip shield 4 .

Note: Tighten the tightening nut with the spanner

37only after a router bit has been inserted.

QConnecting a dust / chip vacuum extraction device

Danger! Protect yourself during your work by wearing a dust mask and use a suitable dust / chip vacuum extraction device.

12 GB