Land Pride | Table of Contents |

Section 4: Maintenance & Lubrication

10.If replacing dishpan (#4), nut on gearbox output shaft should be torqued to 550

3/4" maximum |

blade deflection |

when blade |

bolts are tight |

Cutter Blade Assembly

Figure

Land Pride Cutter Blade Parts

Item Part No. | Part Description |

)

1

2

2 | BLADE SPACER 18 GA. (.062") | |

2 | BLADE SPACER 20 GA. (.036") |

2

3

3

3

4

5

6

Drivelines With Slip Clutches

!CAUTION!

Engage parking brake, disengage PTO, shut off tractor, and remove key before working on or around the driveline and/or slip clutch.

!CAUTION!

Slip clutches that have been in use or have been slipped for only two or three seconds during

Cutter drive components are protected from shock loads by a friction slip clutch. The clutch must be capable of slippage during operation to protect the gearbox, driveline and other drive train parts.

Friction clutches should be

each season and when moisture and/or condensation seizes the inner friction plates.

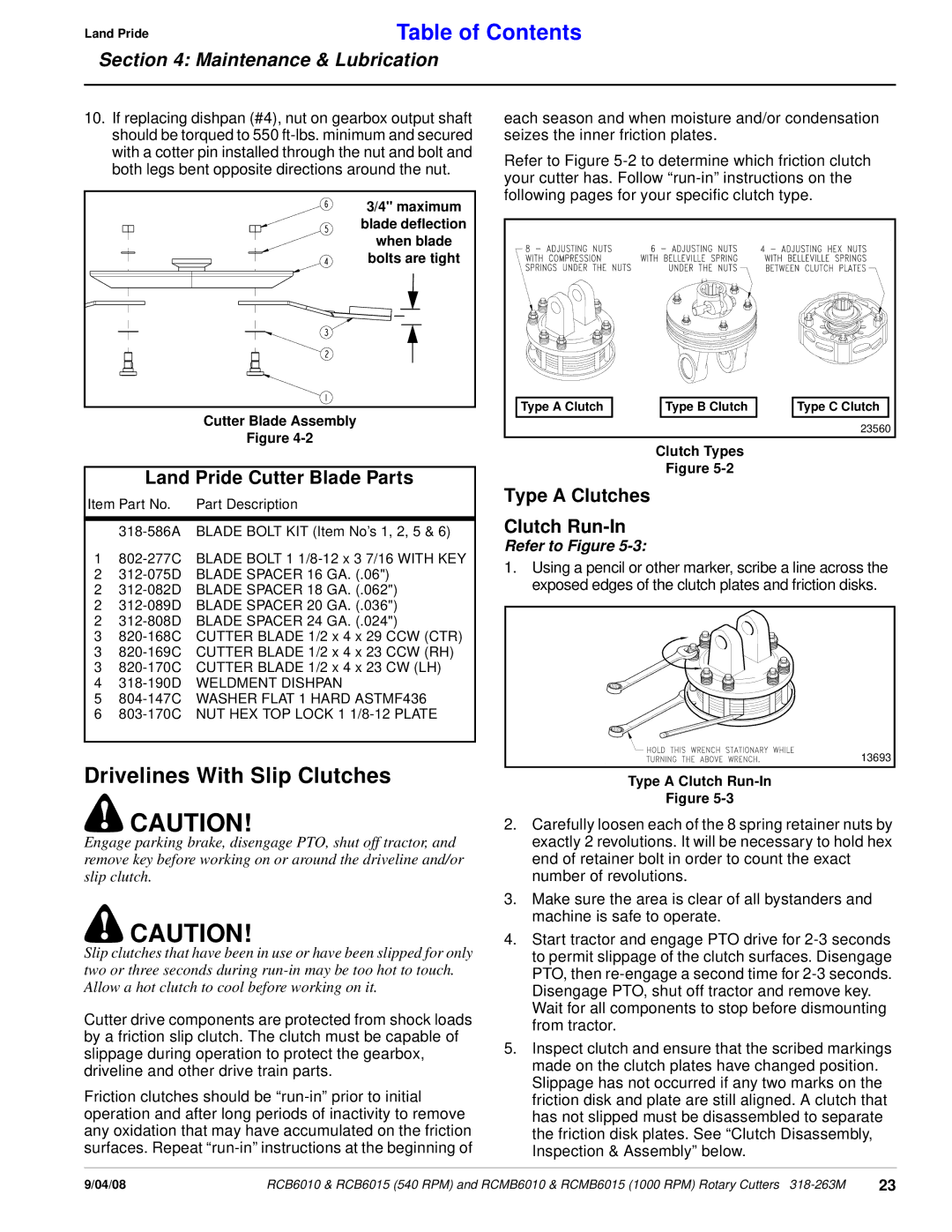

Refer to Figure

Type A Clutch | Type B Clutch | Type C Clutch |

|

| 23560 |

Clutch Types

Figure

Type A Clutches

Clutch Run-In

Refer to Figure 5-3:

1.Using a pencil or other marker, scribe a line across the exposed edges of the clutch plates and friction disks.

13693 |

Type A Clutch

Figure

2.Carefully loosen each of the 8 spring retainer nuts by exactly 2 revolutions. It will be necessary to hold hex end of retainer bolt in order to count the exact number of revolutions.

3.Make sure the area is clear of all bystanders and machine is safe to operate.

4.Start tractor and engage PTO drive for

Wait for all components to stop before dismounting from tractor.

5.Inspect clutch and ensure that the scribed markings made on the clutch plates have changed position. Slippage has not occurred if any two marks on the friction disk and plate are still aligned. A clutch that has not slipped must be disassembled to separate the friction disk plates. See “Clutch Disassembly, Inspection & Assembly” below.

9/04/08 | RCB6010 & RCB6015 (540 RPM) and RCMB6010 & RCMB6015 (1000 RPM) Rotary Cutters | 23 |