Land Pride | Table of Contents |

Section 1: Preparation and

Tractor Requirements

Horsepower

The cutter is designed to be used on tractors with 50 to 250 hp.

Hitch

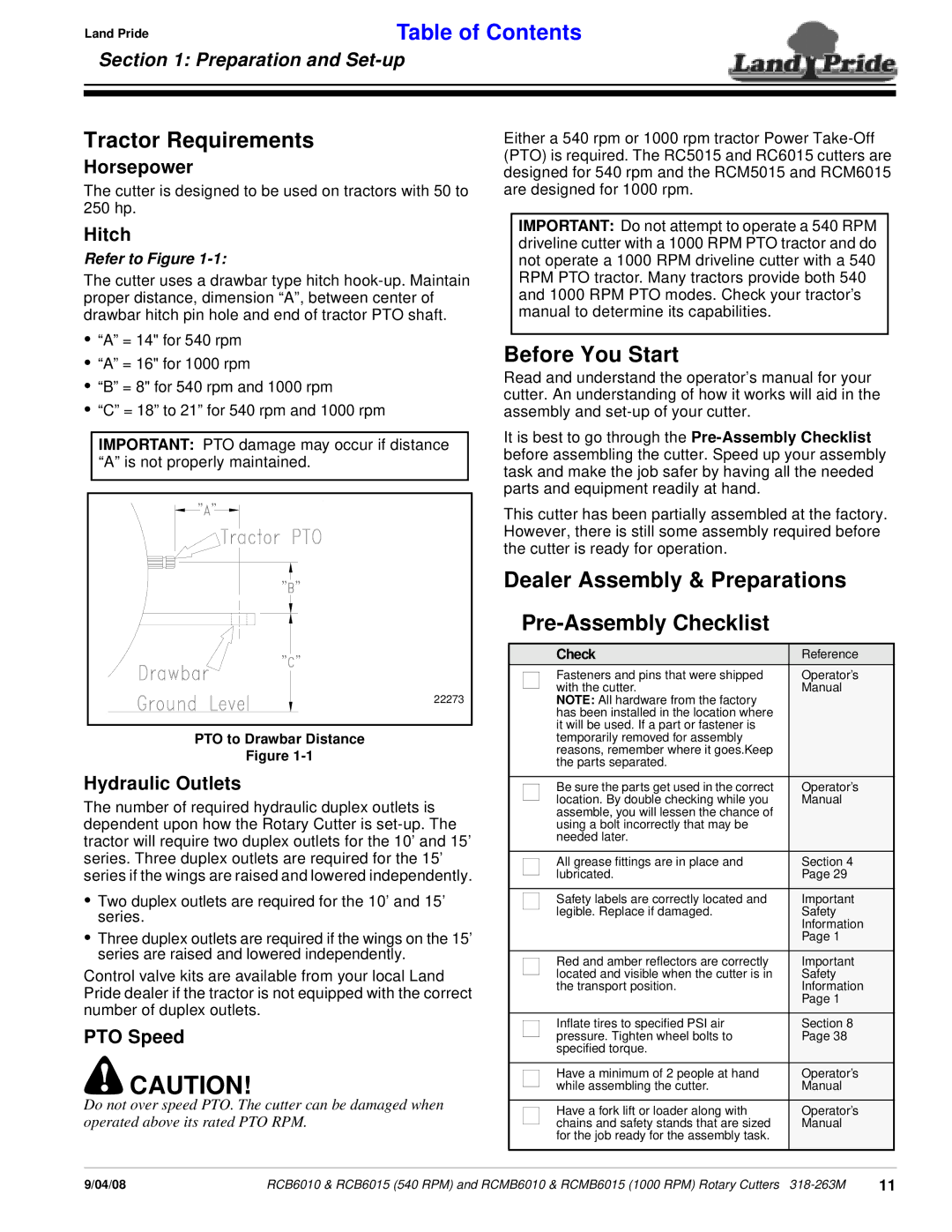

Refer to Figure 1-1:

The cutter uses a drawbar type hitch

•“A” = 14" for 540 rpm

•“A” = 16" for 1000 rpm

•“B” = 8" for 540 rpm and 1000 rpm

•“C” = 18” to 21” for 540 rpm and 1000 rpm

IMPORTANT: PTO damage may occur if distance “A” is not properly maintained.

22273

PTO to Drawbar Distance

Figure

Hydraulic Outlets

The number of required hydraulic duplex outlets is dependent upon how the Rotary Cutter is

•Two duplex outlets are required for the 10’ and 15’ series.

•Three duplex outlets are required if the wings on the 15’ series are raised and lowered independently.

Control valve kits are available from your local Land Pride dealer if the tractor is not equipped with the correct number of duplex outlets.

PTO Speed

!CAUTION!

Do not over speed PTO. The cutter can be damaged when operated above its rated PTO RPM.

Either a 540 rpm or 1000 rpm tractor Power

IMPORTANT: Do not attempt to operate a 540 RPM driveline cutter with a 1000 RPM PTO tractor and do not operate a 1000 RPM driveline cutter with a 540 RPM PTO tractor. Many tractors provide both 540 and 1000 RPM PTO modes. Check your tractor’s manual to determine its capabilities.

Before You Start

Read and understand the operator’s manual for your cutter. An understanding of how it works will aid in the assembly and

It is best to go through the

This cutter has been partially assembled at the factory. However, there is still some assembly required before the cutter is ready for operation.

Dealer Assembly & Preparations

Pre-Assembly Checklist

Check | Reference |

Fasteners and pins that were shipped | Operator’s |

with the cutter. | Manual |

NOTE: All hardware from the factory |

|

has been installed in the location where |

|

it will be used. If a part or fastener is |

|

temporarily removed for assembly |

|

reasons, remember where it goes.Keep |

|

the parts separated. |

|

|

|

Be sure the parts get used in the correct | Operator’s |

location. By double checking while you | Manual |

assemble, you will lessen the chance of |

|

using a bolt incorrectly that may be |

|

needed later. |

|

|

|

All grease fittings are in place and | Section 4 |

lubricated. | Page 29 |

|

|

Safety labels are correctly located and | Important |

legible. Replace if damaged. | Safety |

| Information |

| Page 1 |

|

|

Red and amber reflectors are correctly | Important |

located and visible when the cutter is in | Safety |

the transport position. | Information |

| Page 1 |

|

|

Inflate tires to specified PSI air | Section 8 |

pressure. Tighten wheel bolts to | Page 38 |

specified torque. |

|

|

|

Have a minimum of 2 people at hand | Operator’s |

while assembling the cutter. | Manual |

|

|

Have a fork lift or loader along with | Operator’s |

chains and safety stands that are sized | Manual |

for the job ready for the assembly task. |

|

|

|

9/04/08 | RCB6010 & RCB6015 (540 RPM) and RCMB6010 & RCMB6015 (1000 RPM) Rotary Cutters | 11 |