Land Pride | Table of Contents |

Section 1: Preparation and

Always engage the PTO at low engine rpm to minimize

1.The driveline shaft from the tractor may be either a constant velocity type or a conventional type. Attach the 1

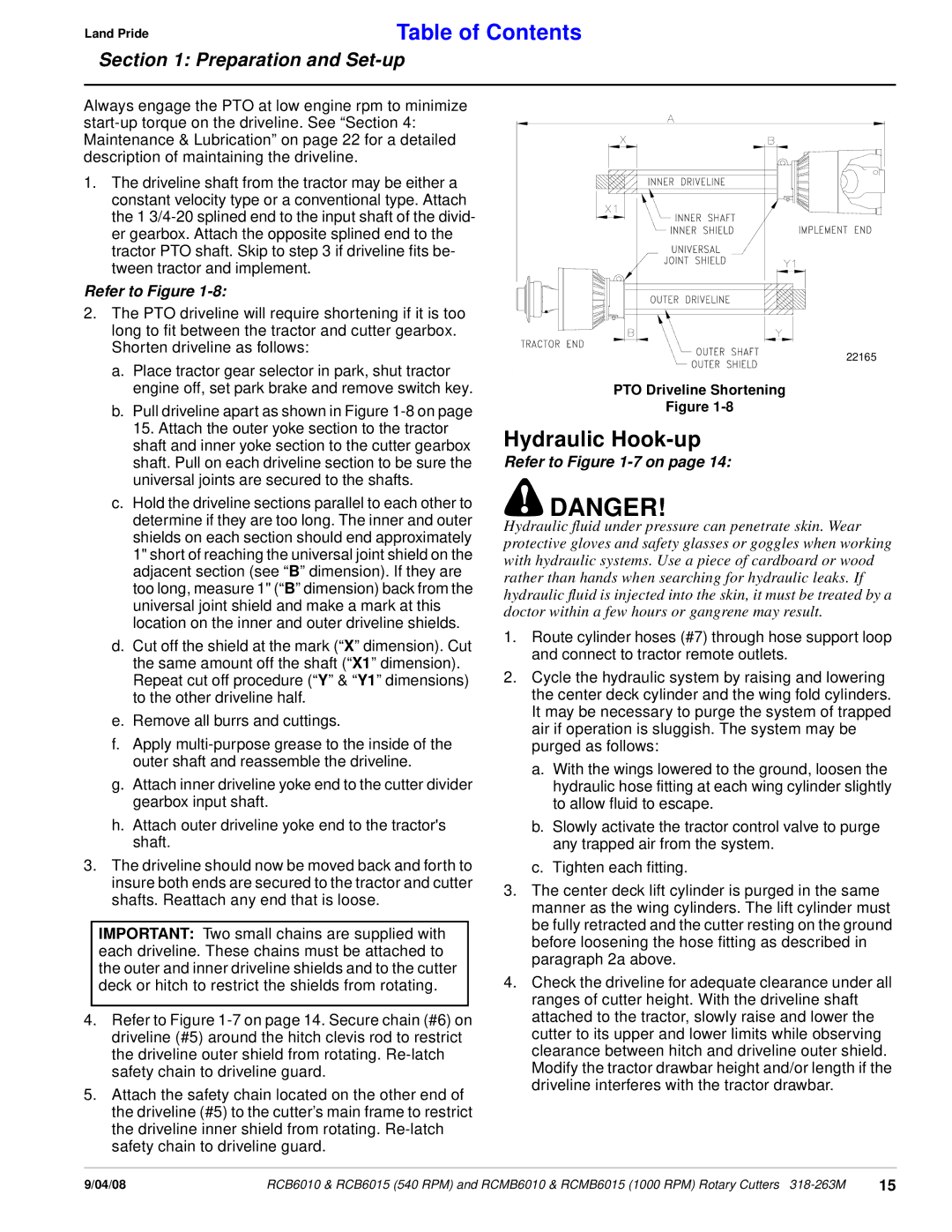

Refer to Figure 1-8:

2.The PTO driveline will require shortening if it is too long to fit between the tractor and cutter gearbox. Shorten driveline as follows:

a.Place tractor gear selector in park, shut tractor engine off, set park brake and remove switch key.

b.Pull driveline apart as shown in Figure

c.Hold the driveline sections parallel to each other to determine if they are too long. The inner and outer shields on each section should end approximately 1" short of reaching the universal joint shield on the adjacent section (see “B” dimension). If they are too long, measure 1" (“B” dimension) back from the universal joint shield and make a mark at this location on the inner and outer driveline shields.

d.Cut off the shield at the mark (“X” dimension). Cut the same amount off the shaft (“X1” dimension). Repeat cut off procedure (“Y” & “Y1” dimensions) to the other driveline half.

e.Remove all burrs and cuttings.

f.Apply

g.Attach inner driveline yoke end to the cutter divider gearbox input shaft.

h.Attach outer driveline yoke end to the tractor's shaft.

3.The driveline should now be moved back and forth to insure both ends are secured to the tractor and cutter shafts. Reattach any end that is loose.

IMPORTANT: Two small chains are supplied with each driveline. These chains must be attached to the outer and inner driveline shields and to the cutter deck or hitch to restrict the shields from rotating.

4.Refer to Figure

5.Attach the safety chain located on the other end of the driveline (#5) to the cutter’s main frame to restrict the driveline inner shield from rotating.

22165

PTO Driveline Shortening

Figure

Hydraulic Hook-up

Refer to Figure 1-7 on page 14:

!DANGER!

Hydraulic fluid under pressure can penetrate skin. Wear protective gloves and safety glasses or goggles when working with hydraulic systems. Use a piece of cardboard or wood rather than hands when searching for hydraulic leaks. If hydraulic fluid is injected into the skin, it must be treated by a doctor within a few hours or gangrene may result.

1.Route cylinder hoses (#7) through hose support loop and connect to tractor remote outlets.

2.Cycle the hydraulic system by raising and lowering the center deck cylinder and the wing fold cylinders. It may be necessary to purge the system of trapped air if operation is sluggish. The system may be purged as follows:

a.With the wings lowered to the ground, loosen the hydraulic hose fitting at each wing cylinder slightly to allow fluid to escape.

b.Slowly activate the tractor control valve to purge any trapped air from the system.

c.Tighten each fitting.

3.The center deck lift cylinder is purged in the same manner as the wing cylinders. The lift cylinder must be fully retracted and the cutter resting on the ground before loosening the hose fitting as described in paragraph 2a above.

4.Check the driveline for adequate clearance under all ranges of cutter height. With the driveline shaft attached to the tractor, slowly raise and lower the cutter to its upper and lower limits while observing clearance between hitch and driveline outer shield. Modify the tractor drawbar height and/or length if the driveline interferes with the tractor drawbar.

9/04/08 | RCB6010 & RCB6015 (540 RPM) and RCMB6010 & RCMB6015 (1000 RPM) Rotary Cutters | 15 |