Planned Service

A service technician should check the following items dur- ing an annual inspection. Power to the unit must be shut off for safety.

Fresh air grilles and louvers (on the unit and in the room where the furnace is installed) − Must be open and unob- structed to provide combustion air.

Burners − Must be inspected for rust, dirt, or signs of water.

Vent pipe − Must be inspected for signs of water, cracked, damaged or sagging pipe, or disconnected joints.

Unit appearance − Must be inspected for rust, dirt, signs of water, burnt or damaged wires, or components.

Blower access door − Must be properly in place and pro- vide a seal between the return air and the room where the furnace is installed.

Return air duct − Must be properly attached and provide an air seal to the unit.

Operating performance − Unit must be observed during operation to monitor proper performance of the unit and the vent system.

Combustion gases − Flue products must be analyzed and compared to the unit specifications.

Problems detected during the inspection may make it nec- essary to temporarily shut down the furnace until the items can be repaired or replaced.

Instruct the homeowners to pay attention to their furnace. Situations can arise between annual furnace in- spections that may result in unsafe operation. For instance, items innocently stored next to the furnace may obstruct the combustion air supply. This could cause incomplete combustion and the production of carbon monoxide gas.

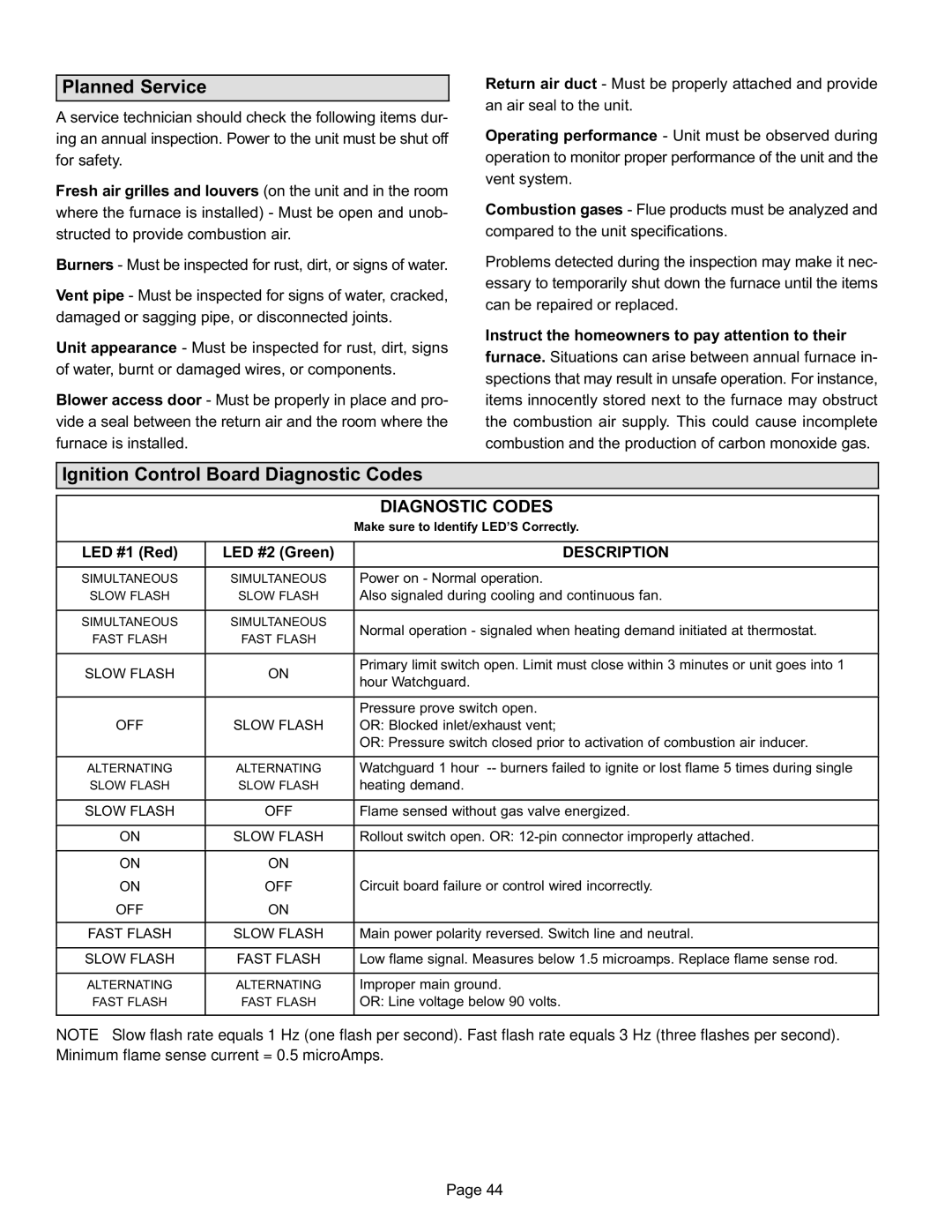

Ignition Control Board Diagnostic Codes

|

| DIAGNOSTIC CODES | |

|

| Make sure to Identify LED’S Correctly. | |

|

|

| |

LED #1 (Red) | LED #2 (Green) | DESCRIPTION | |

|

|

| |

SIMULTANEOUS | SIMULTANEOUS | Power on − Normal operation. | |

SLOW FLASH | SLOW FLASH | Also signaled during cooling and continuous fan. | |

|

|

| |

SIMULTANEOUS | SIMULTANEOUS | Normal operation − signaled when heating demand initiated at thermostat. | |

FAST FLASH | FAST FLASH | ||

| |||

|

|

| |

SLOW FLASH | ON | Primary limit switch open. Limit must close within 3 minutes or unit goes into 1 | |

hour Watchguard. | |||

|

| ||

|

|

| |

|

| Pressure prove switch open. | |

OFF | SLOW FLASH | OR: Blocked inlet/exhaust vent; | |

|

| OR: Pressure switch closed prior to activation of combustion air inducer. | |

|

|

| |

ALTERNATING | ALTERNATING | Watchguard 1 hour −− burners failed to ignite or lost flame 5 times during single | |

SLOW FLASH | SLOW FLASH | heating demand. | |

|

|

| |

SLOW FLASH | OFF | Flame sensed without gas valve energized. | |

|

|

| |

ON | SLOW FLASH | Rollout switch open. OR: | |

|

|

|

ON ON OFF

ON

OFF

ON

Circuit board failure or control wired incorrectly.

FAST FLASH | SLOW FLASH | Main power polarity reversed. Switch line and neutral. |

|

|

|

SLOW FLASH | FAST FLASH | Low flame signal. Measures below 1.5 microamps. Replace flame sense rod. |

|

|

|

ALTERNATING | ALTERNATING | Improper main ground. |

FAST FLASH | FAST FLASH | OR: Line voltage below 90 volts. |

|

|

|

NOTE − Slow flash rate equals 1 Hz (one flash per second). Fast flash rate equals 3 Hz (three flashes per second). Minimum flame sense current = 0.5 microAmps.

Page 44