OPERATION | ||

|

|

|

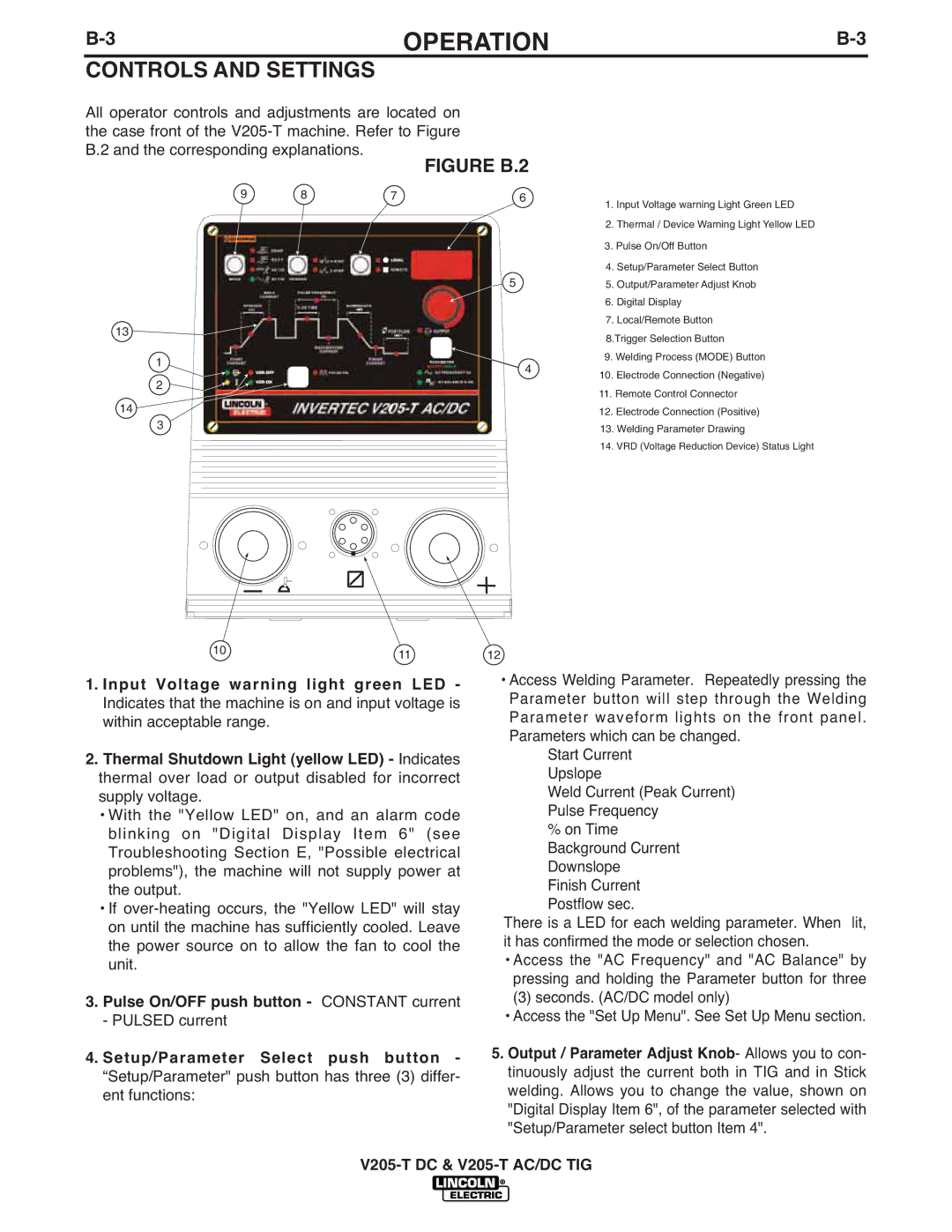

CONTROLS AND SETTINGS

All operator controls and adjustments are located on the case front of the

|

| FIGURE B.2 |

| |

9 | 8 | 7 | 6 | 1. Input Voltage warning Light Green LED |

|

|

|

| |

|

|

|

| 2. Thermal / Device Warning Light Yellow LED |

|

|

|

| 3. Pulse On/Off Button |

|

| LOCAL |

| 4. Setup/Parameter Select Button |

|

|

|

| |

|

| 5 |

| 5. Output/Parameter Adjust Knob |

|

| sec |

| 6. Digital Display |

|

|

|

| |

13 |

|

|

| 7. Local/Remote Button |

| sec |

| 8.Trigger Selection Button | |

|

|

|

| |

1 |

|

| 4 | 9. Welding Process (MODE) Button |

|

|

| ||

| VDR OFF |

| 10. Electrode Connection (Negative) | |

2 | VDR ON |

|

| |

|

|

| ||

|

|

| 11. Remote Control Connector | |

|

|

|

| |

14 |

|

|

| 12. Electrode Connection (Positive) |

3 |

|

|

| 13. Welding Parameter Drawing |

|

|

|

| |

|

|

|

| 14. VRD (Voltage Reduction Device) Status Light |

10 | 11 | 12 |

|

1.Input Voltage warning light green LED - Indicates that the machine is on and input voltage is within acceptable range.

2.Thermal Shutdown Light (yellow LED) - Indicates thermal over load or output disabled for incorrect supply voltage.

•With the "Yellow LED" on, and an alarm code blinking on "Digital Display Item 6" (see Troubleshooting Section E, "Possible electrical problems"), the machine will not supply power at the output.

•If

3.Pulse On/OFF push button - CONSTANT current - PULSED current

4.Setup/Parameter Select push button - “Setup/Parameter" push button has three (3) differ- ent functions:

•Access Welding Parameter. Repeatedly pressing the Parameter button will step through the Welding Parameter waveform lights on the front panel. Parameters which can be changed.

Start Current Upslope

Weld Current (Peak Current)

Pulse Frequency

%on Time Background Current Downslope Finish Current Postflow sec.

There is a LED for each welding parameter. When lit, it has confirmed the mode or selection chosen.

•Access the "AC Frequency" and "AC Balance" by pressing and holding the Parameter button for three

(3) seconds. (AC/DC model only)

•Access the "Set Up Menu". See Set Up Menu section.

5.Output / Parameter Adjust Knob- Allows you to con- tinuously adjust the current both in TIG and in Stick welding. Allows you to change the value, shown on "Digital Display Item 6", of the parameter selected with "Setup/Parameter select button Item 4".