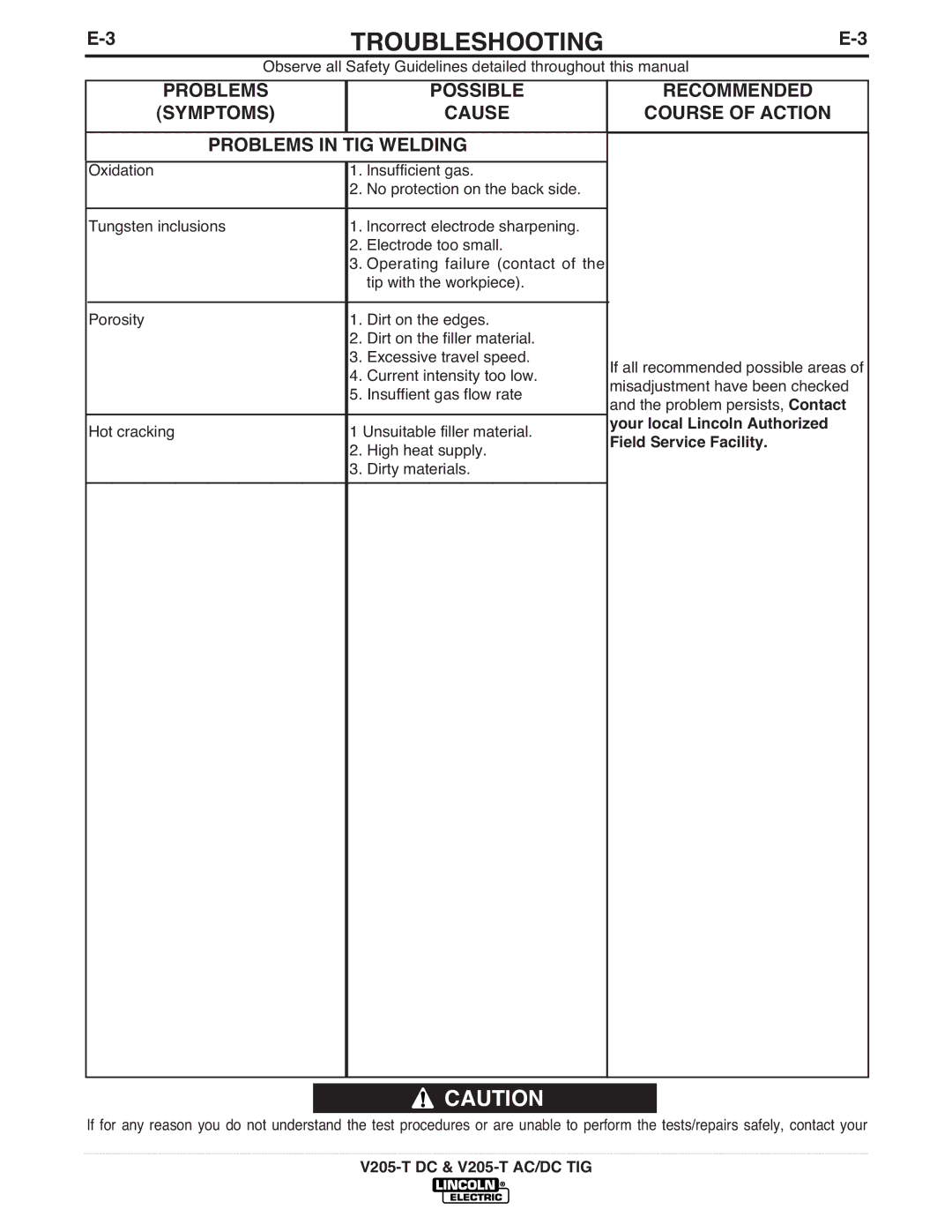

| TROUBLESHOOTING | ||||

|

|

|

|

| |

| Observe all Safety Guidelines detailed throughout this manual | ||||

|

|

|

|

| |

| PROBLEMS |

| POSSIBLE | RECOMMENDED | |

| (SYMPTOMS) |

| CAUSE | COURSE OF ACTION | |

| PROBLEMS IN | TIG WELDING |

| ||

Oxidation | 1. lnsufficient gas. |

| |||

|

| 2. | No protection on the back side. |

| |

|

|

| |||

Tungsten inclusions | 1. lncorrect electrode sharpening. |

| |||

|

| 2. | Electrode too small. |

| |

|

| 3. | Operating failure (contact of the |

| |

|

|

| tip with the workpiece). |

| |

|

|

| |||

Porosity | 1. Dirt on the edges. |

| |||

|

| 2. | Dirt on the filler material. |

| |

|

| 3. | Excessive travel speed. | If all recommended possible areas of | |

|

| 4. | Current intensity too low. | ||

|

| misadjustment have been checked | |||

|

| 5. | Insuffient gas flow rate | ||

|

| and the problem persists, Contact | |||

|

|

|

| ||

Hot cracking | 1 Unsuitable filler material. | your local Lincoln Authorized | |||

Field Service Facility. | |||||

|

| 2. | High heat supply. | ||

|

|

| |||

|

| 3. | Dirty materials. |

| |

|

|

|

|

| |

|

|

|

|

| |

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your