OPERATION | ||

|

|

|

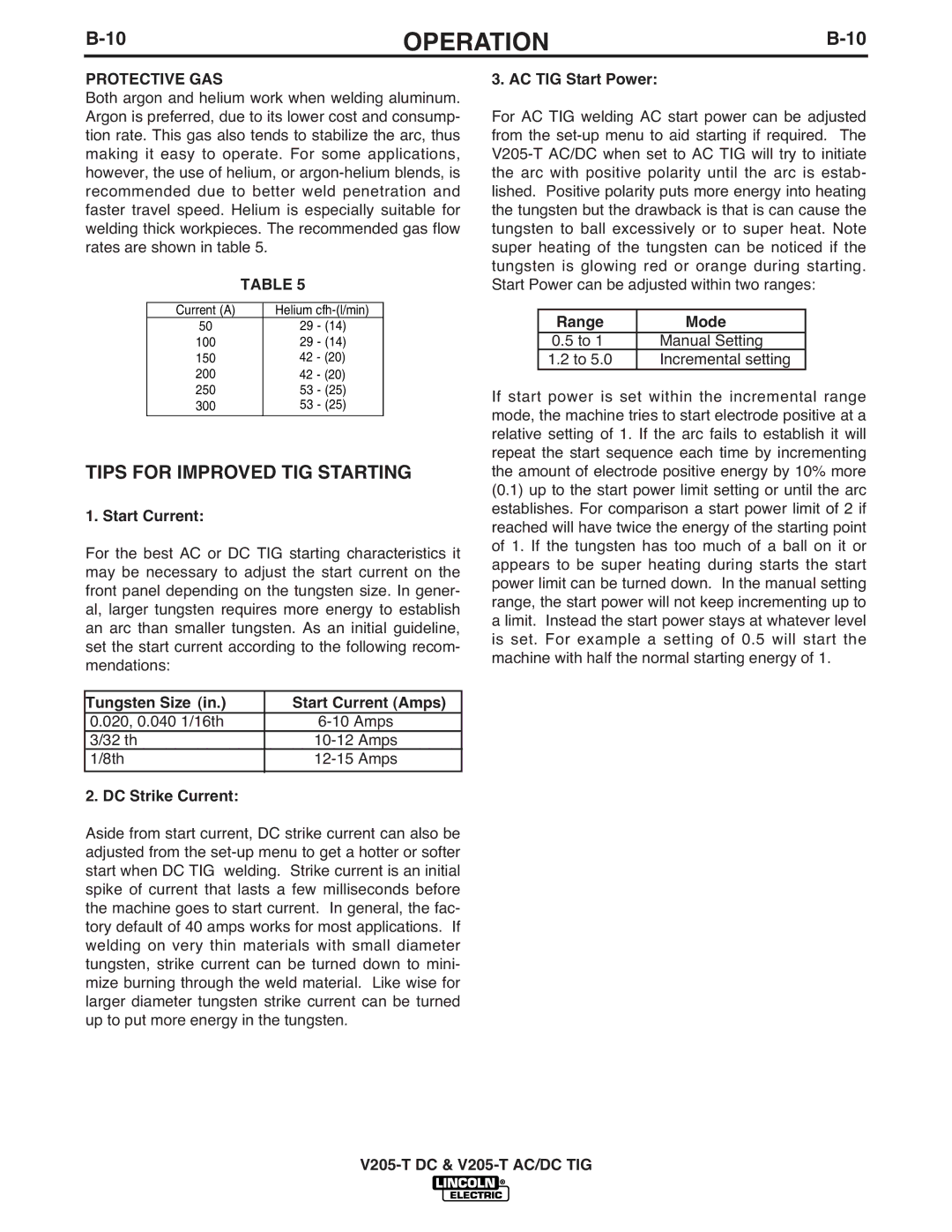

PROTECTIVE GAS

Both argon and helium work when welding aluminum. Argon is preferred, due to its lower cost and consump- tion rate. This gas also tends to stabilize the arc, thus making it easy to operate. For some applications, however, the use of helium, or

| TABLE 5 | |

Current (A) |

| Helium |

50 |

| 29 - (14) |

100 |

| 29 - (14) |

150 |

| 42 - (20) |

200 |

| 42 - (20) |

250 |

| 53 - (25) |

300 |

| 53 - (25) |

|

|

|

TIPS FOR IMPROVED TIG STARTING

1. Start Current:

For the best AC or DC TIG starting characteristics it may be necessary to adjust the start current on the front panel depending on the tungsten size. In gener- al, larger tungsten requires more energy to establish an arc than smaller tungsten. As an initial guideline, set the start current according to the following recom- mendations:

Tungsten Size (in.) | Start Current (Amps) |

0.020, 0.040 1/16th | |

3/32 th | |

1/8th | |

|

|

2. DC Strike Current: |

|

Aside from start current, DC strike current can also be adjusted from the

3. AC TIG Start Power:

For AC TIG welding AC start power can be adjusted from the

Range | Mode |

0.5to 1 Manual Setting

1.2to 5.0 Incremental setting

If start power is set within the incremental range mode, the machine tries to start electrode positive at a relative setting of 1. If the arc fails to establish it will repeat the start sequence each time by incrementing the amount of electrode positive energy by 10% more (0.1) up to the start power limit setting or until the arc establishes. For comparison a start power limit of 2 if reached will have twice the energy of the starting point of 1. If the tungsten has too much of a ball on it or appears to be super heating during starts the start power limit can be turned down. In the manual setting range, the start power will not keep incrementing up to a limit. Instead the start power stays at whatever level is set. For example a setting of 0.5 will start the machine with half the normal starting energy of 1.